Floor plastic rubber lock catch convenient for connecting and positioning

A plastic and flooring technology, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of panel deformation, processing difficulties, poor elasticity, etc., and achieve the effect of reducing maintenance and expanding the use function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

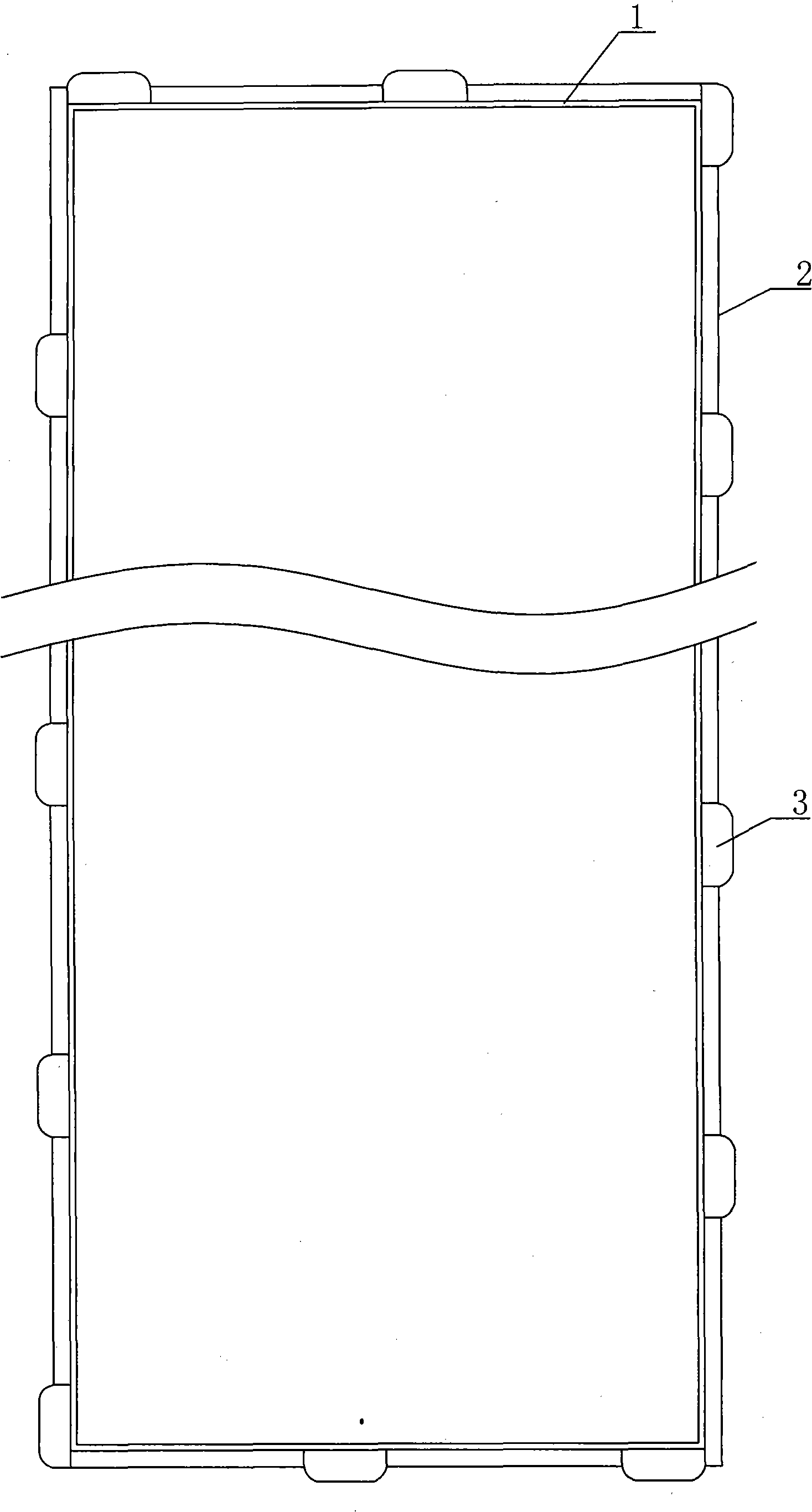

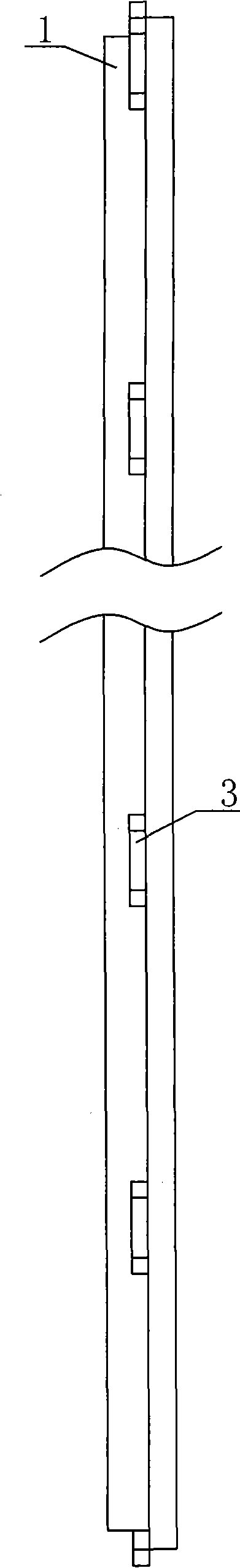

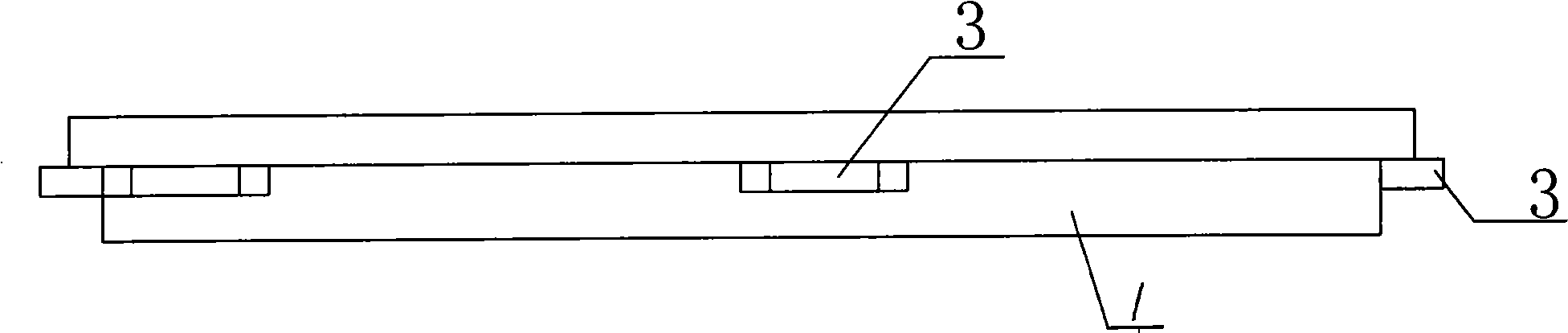

[0051] A floor plastic lock that is convenient for connection and positioning, such asfigure 1 , figure 2 , image 3 , Figure 4 In the shown embodiment 1, a plastic frame 1 is arranged on the periphery of the wooden floor or the fiber plywood floor, and stepped guide rails 2 shrinking inward are respectively arranged on the lower part of the outer surface of the plastic frame 1. On the stepped guide rails 2, respectively, The plastic sliders 3 whose outer ends protrude from the guide rail surface are uniformly arranged to match the guide rail surface of the corresponding assembled floor frame ladder guide rail 2. When assembling, the plastic slider 3 slides along the guide rail 2 to make the plastic slider and the assembled floor ladder guide rail. Matching positioning of the plastic slider. Figure 4 , Figure 5 , Image 6 , Figure 7 In the shown embodiment 2, plastic sliders 3 whose outer ends protrude from the surface of the guide rail are evenly distributed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com