Diamond grinding wheel and manufacturing method thereof

A diamond grinding wheel and diamond technology, which is applied in bonded grinding wheels, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult balance between grinding efficiency and machining accuracy, and achieve hard to burn workpieces, high grinding efficiency, and good surface finish Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

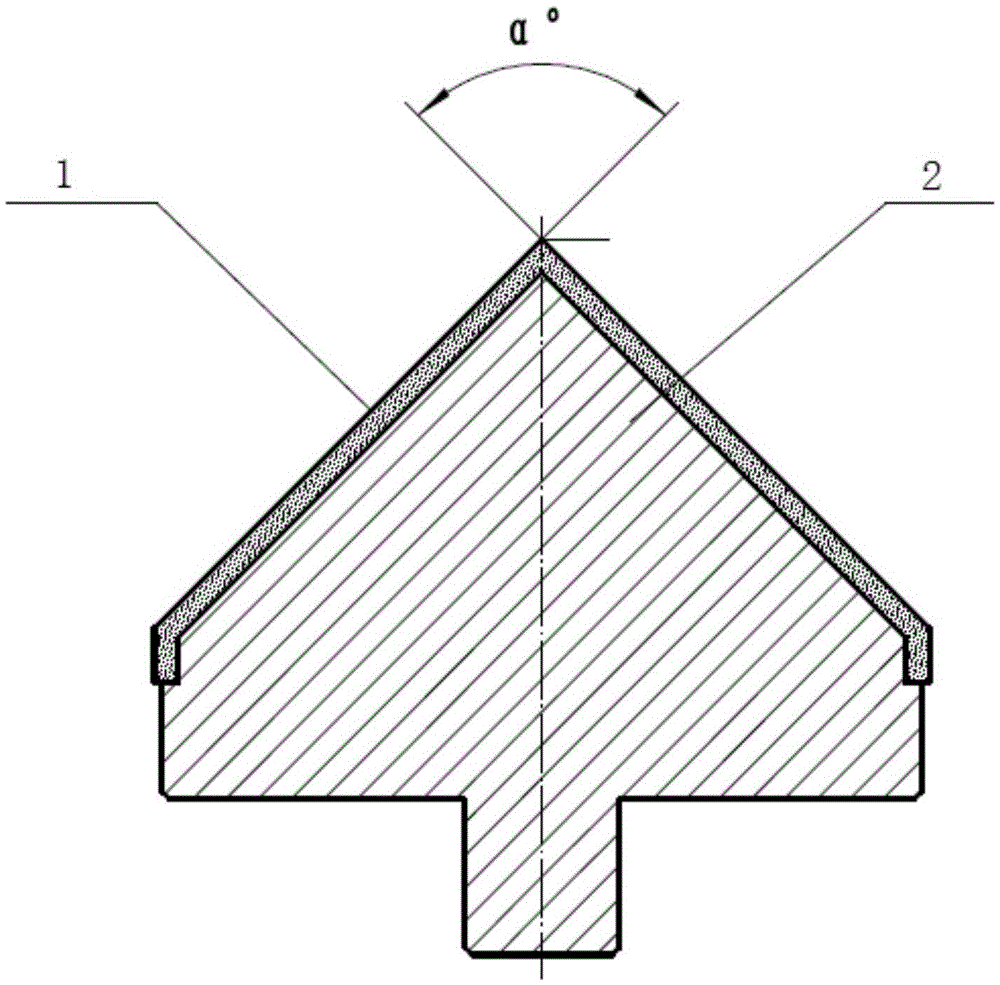

[0028] The diamond grinding wheel of the present embodiment, as figure 1 As shown, it includes a grinding wheel base 2 and an abrasive layer 1 attached to the grinding wheel base 2; the grinding wheel base is a cast aluminum base with a tensile strength ≥ 150Mpa; the grinding wheel base 2 includes a grinding part and is integrally formed with the grinding part The mounting part, the grinding part has a conical protrusion, and the abrasive layer 1 is arranged on the outer conical surface.

[0029] The diamond grinding wheel of the present embodiment is a rough grinding wheel, and the CN56 type nickel-plated diamond abrasive of 120# is selected as the diamond abrasive, and is made up of the following components in volume percentage: 20% of diamond abrasive, 45% of phenolic resin, 10% of carbonyl iron, cryolite 10%, graphite 15%.

[0030] The preparation method of the diamond grinding wheel of the present embodiment may further comprise the steps:

[0031] 1) Diamond abrasives,...

Embodiment 2

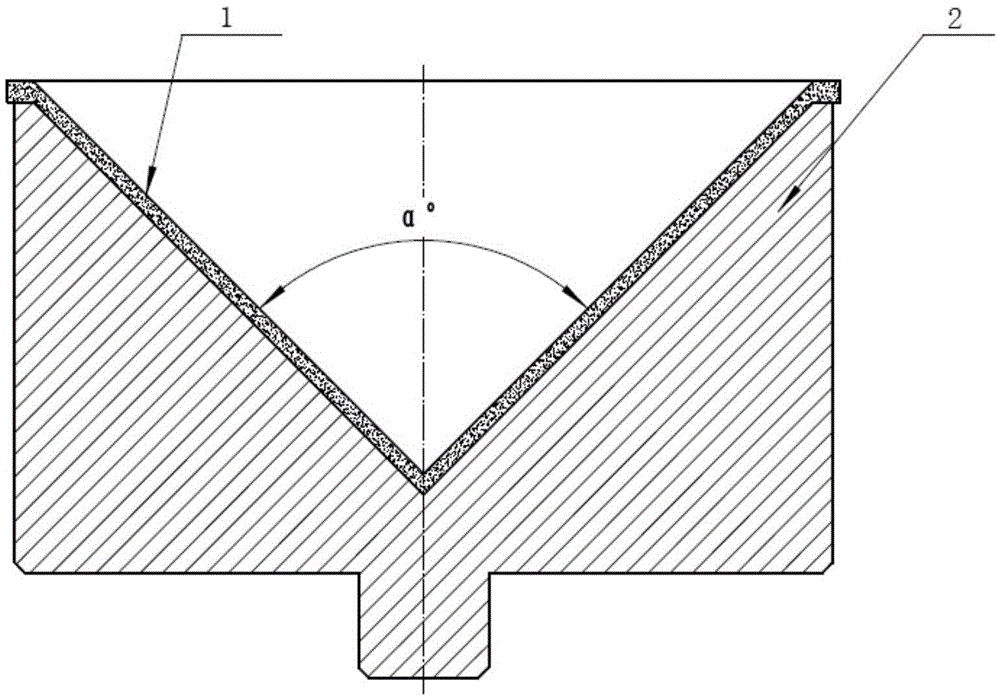

[0034]The present embodiment diamond grinding wheel, as figure 2 As shown, it includes a grinding wheel base 2 and an abrasive layer 1 attached to the grinding wheel base 2; the grinding wheel base is a cast aluminum base with a tensile strength ≥ 150Mpa; the grinding wheel base 2 includes a grinding part and a mounting part, and the grinding wheel An inverted conical groove is arranged on the cutting part, and the abrasive layer 1 is arranged on the inner surface of the inverted conical groove.

[0035] The diamond grinding wheel of the present embodiment is a coarse grinding wheel, and the CN56 type nickel-plated diamond abrasive of diamond abrasive selection 200# is made up of the following components of volume percentage: diamond abrasive 21%, phenolic resin 46%, carbonyl iron 10%, cryolite 8%, graphite 15%.

[0036] The preparation method of the diamond grinding wheel of the present embodiment may further comprise the steps:

[0037] 1) Diamond abrasives, phenolic resi...

Embodiment 3~8

[0040] The diamond grinding wheels of Examples 3-8 are coarse grinding wheels, and the composition and the shape of the grinding part are shown in Table 1.

[0041] The composition and the shape of the grinding part of the diamond grinding wheel used for rough grinding of Table 1 Examples 3 to 8

[0042]

[0043] The preparation method of the diamond grinding wheel of Examples 3-5 is the same as that of Example 1; the preparation method of the diamond grinding wheel of Examples 6-8 is the same as that of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com