Surface processing method of strip laser medium

A laser medium and surface processing technology, applied in metal processing equipment, surface-polished machine tools, manufacturing tools, etc., can solve problems such as crystal chipping, chipping damage, and difficulty in processing and manufacturing slab laser media, and achieve surface accuracy. High, surface shape accuracy and polishing efficiency are improved, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

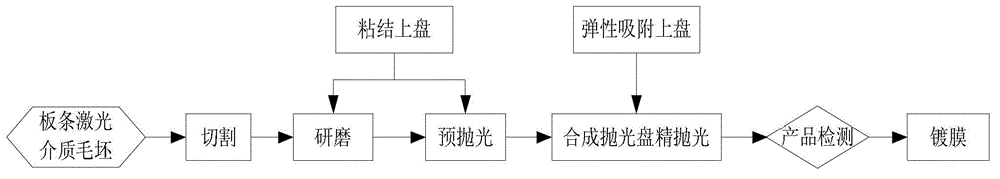

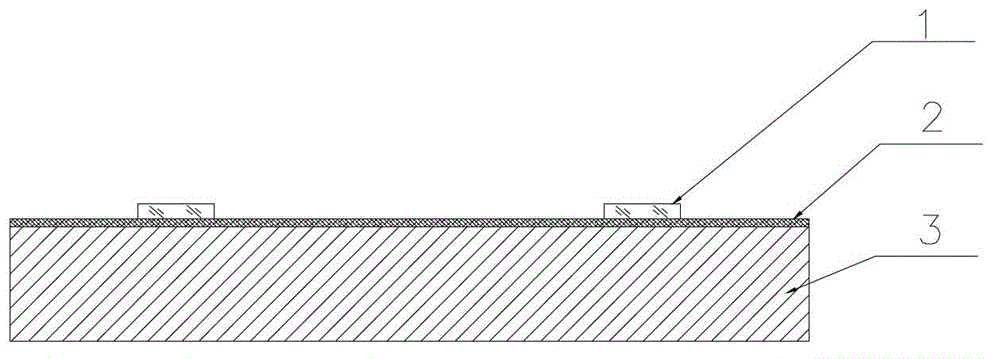

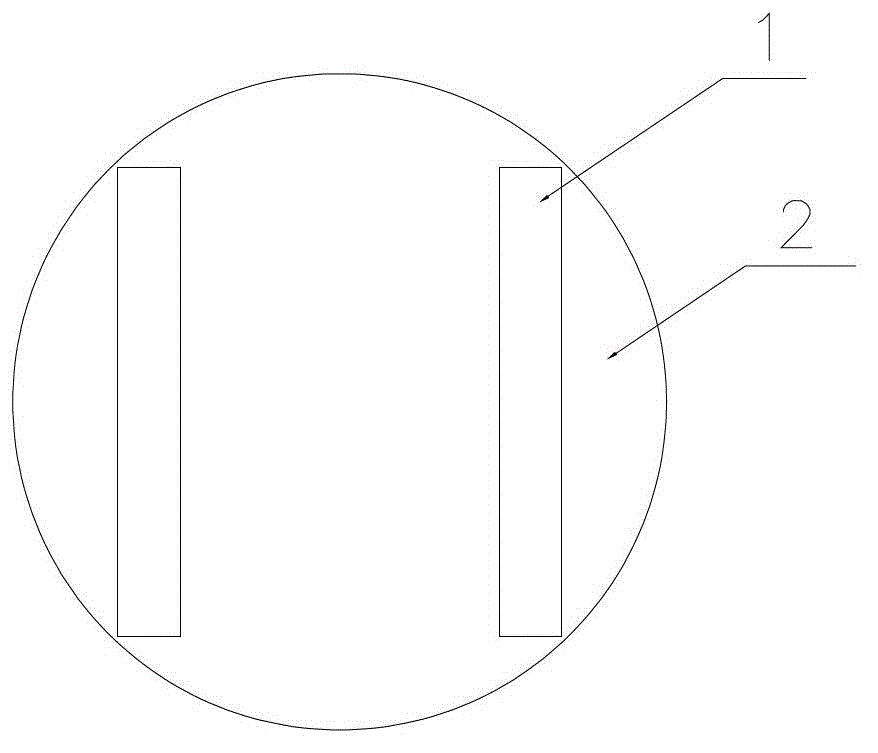

[0016] The technological process of the surface processing method of the slab laser medium of the present invention is as figure 1 As shown, the surface processing method of the slab laser medium of the present invention includes the following steps: (1) firstly use an adhesive to bond the slab laser medium 1 after cutting to the disk, and grind the slab laser medium 1 on a plane grinder. The laser medium is ground and pre-polished, and after the pre-polishing of the first large surface of the slab laser medium 1 is completed, the plate is lowered, turned over, and then the second large surface is bonded, ground, and pre-polished.

[0017] Among them, the binder used for the upper disc is paraffin or asphalt, the grinding disc on the surface grinder is an iron disc or copper disc, the pre-polished polishing disc is made of asphalt or polyurethane, and the grinding liquid is silicon carbide. Green silicon carbide with better purity. Polishing liquid is diamond or Al 2 o 3 Mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com