Machining method for punching small hole on glass

A processing method and hole processing technology, which are applied in the processing field of small holes punched by a green laser in glass after pressing, can solve the problems of low punching yield and output yield, poor hole collapse, and poor surface discoloration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

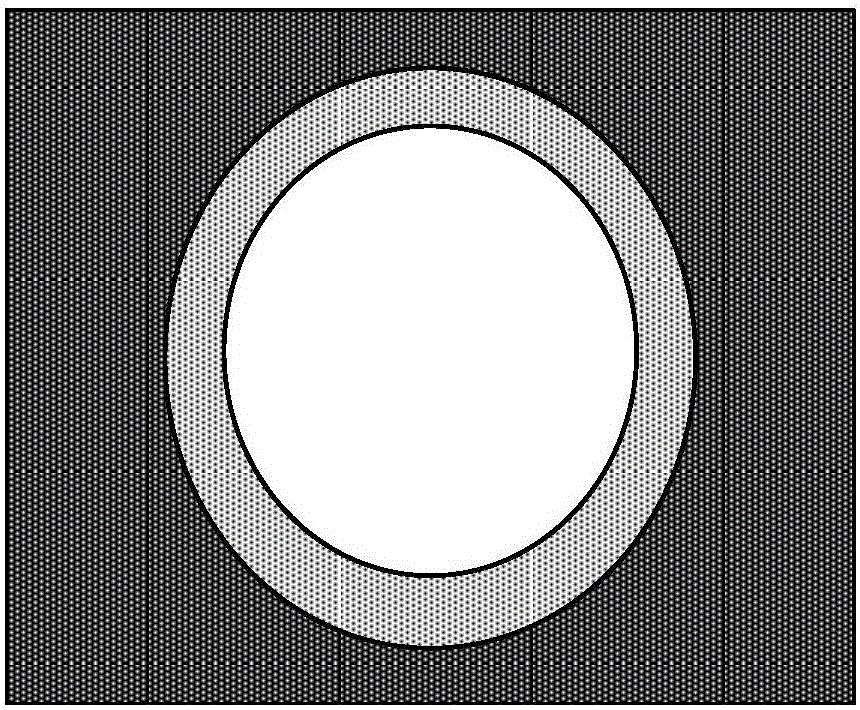

[0042] image 3 A schematic diagram of the AS surface of glass in the processing method for punching small holes in glass provided by the embodiment of the present invention; Figure 4 A schematic diagram of the BM surface of the glass in the processing method for drilling small holes in the glass provided by the embodiment of the present invention.

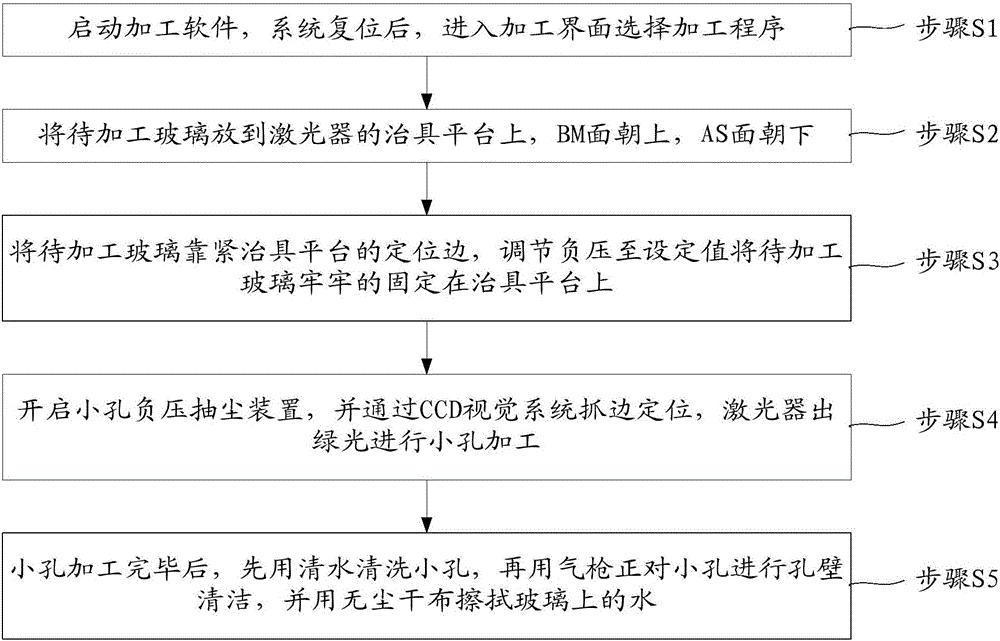

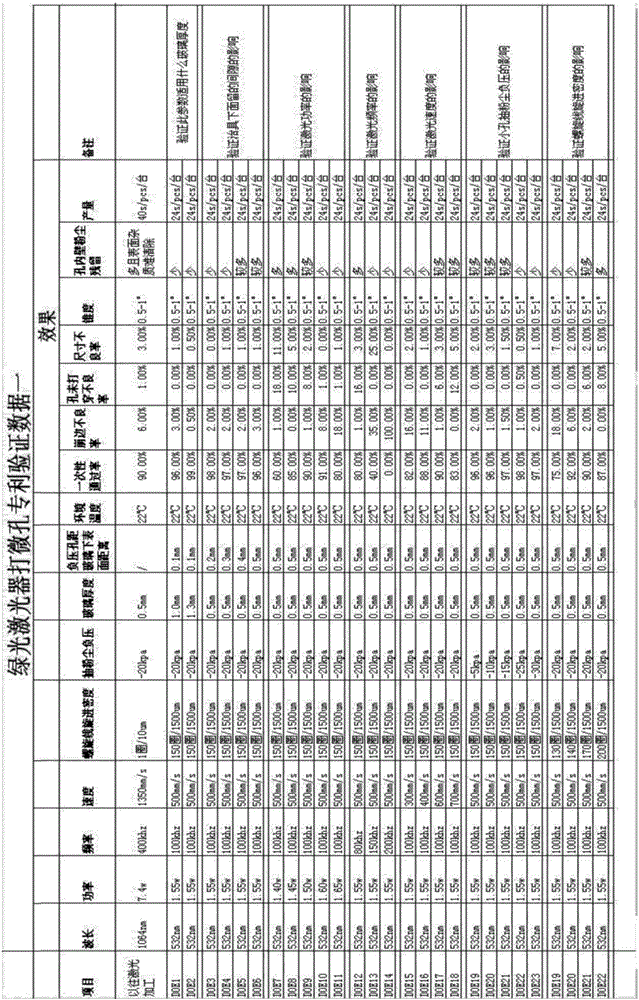

[0043] An embodiment of the present invention provides a processing method for punching a small hole in glass with a green laser after pressurization, comprising the following steps: the first step, starting the processing software, after the system is reset, enter the processing interface and select the program for processing a 0.5mm hole; the second Step 1. Put the 1.3mm thick glass on the fixture platform of the laser, with the BM facing up (such as Figure 4 shown), AS face down (as image 3 shown); the third step is to close the glass to be processed to the positioning edge of the jig platform, start the base suction butto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com