Method and device for correlative multi-focus laser separation of fragile transmission material

A multi-focus, through-beam technology, used in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the ideal design of laser multi-focus position and focus energy distribution, affect the thickness and quality of cutting and separation materials, The laser focus energy distribution is quite different and other problems, to achieve high-quality safe cutting separation, large practical use value, and improve the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

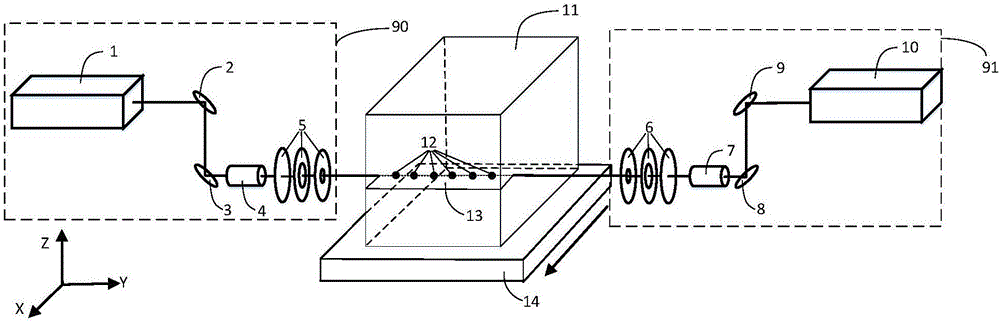

[0027] The technical solution provided by the present invention can be completed by one embodiment, and there are two specific embodiments for the composition and optical path of the multifocal lens group. The specific implementation includes the following steps:

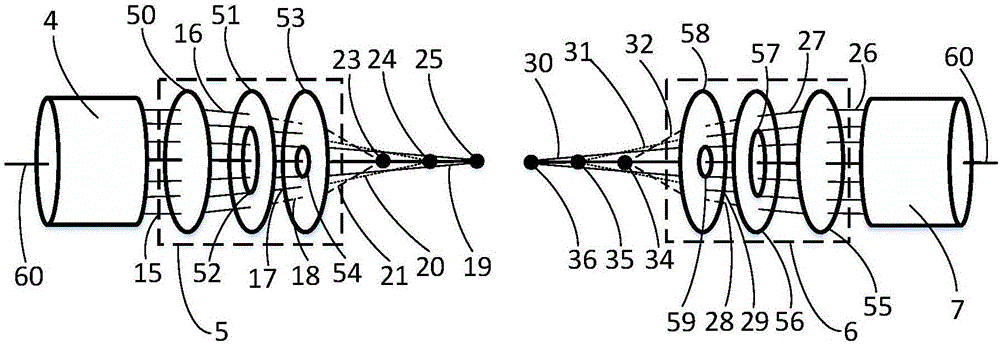

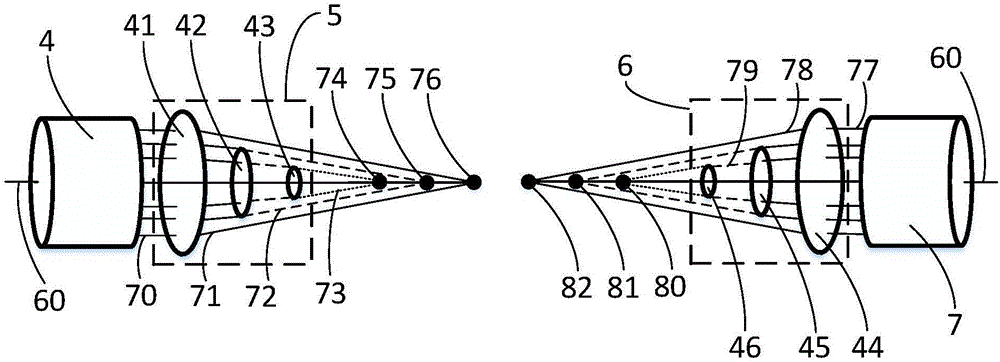

[0028] (1) Two sets of multifocal lens groups are composed of a series of focusing lenses with small holes in the center or different diameters. Among them, the number, focal length, aperture diameter, or focusing lens diameter of each focusing lens is determined by the thickness, absorptivity, refractive index and other parameters of the cut brittle transmission material. Adjust the distance of each focusing lens to make the laser focus position moderate.

[0029] (2) The laser, light guide mirror, and beam expander form the first laser processing system, and the multifocal lens group is placed in front of the first laser processing system so that its optical axis is coaxial. Among them, the choice of laser type is de...

example 1

[0041] Two YLM-150 model fiber lasers are used as the first and second lasers, with an output wavelength of 1070nm and a maximum output power of 150W. The cutting material is KDP optical crystal, and the cutting size is 150mm×150mm×150mm. Two sets of identical lens groups are formed by using 1 conventional focusing lens and 2 focusing lenses with different diameters. Each laser beam will produce 3 laser focal points after passing through the lens group. The distance between the laser focal points is 20mm, and the laser energy The distribution (laser focus is arranged in sequence along the laser transmission direction) ratio is 30%, 30%, 40%. The two sets of laser processing systems produce a total of 6 laser focal points, and the center distance between the two sets of laser focal points produced by the two sets of laser processing is 20mm. Experimental method: The first and second laser processing systems emit light at the same time, and the laser output power is adjusted to ...

example 2

[0043] Two SD-YAG-600W Nd:YAG lasers are used as the first and second lasers, with an output wavelength of 1064nm and a maximum output power of 600W. The cutting material is quartz material, and the cutting size is 200mm×200mm×200mm. Two sets of identical lens groups are formed by using 1 conventional focusing lens and 2 focusing lenses with a small hole in the center. Each laser beam will produce 3 laser focal points after passing through the lens group. The distance between the laser focal points is 30mm. The energy distribution (laser focus is arranged in sequence along the laser transmission direction) ratio is 30%, 30%, 40%. The two sets of laser processing systems produce a total of 6 laser focal points, and the center distance between the two sets of laser focal points produced by the two sets of laser processing is 20mm. Experimental method: The first and second laser processing systems emit light at the same time, and the output power of the two lasers is adjusted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com