Method for processing three-dimensional contour of transparent material

A technology of transparent materials and three-dimensional contours, applied in metal processing equipment, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of not achieving the separation effect and unseparated processing materials, so as to ensure absolute uniformity and avoid fine debris , Improve the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

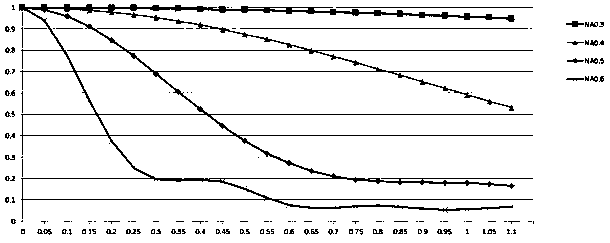

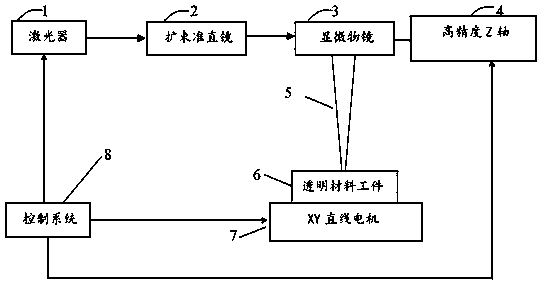

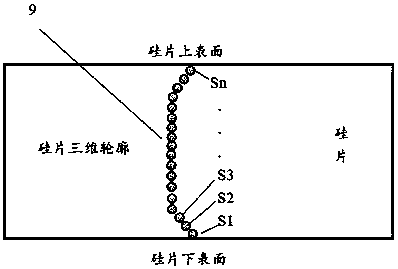

[0078] Please also refer to figure 2 with image 3 , Figure 4 , the present embodiment provides a method for processing a three-dimensional contour of a silicon wafer. The transparent material workpiece 6 is a silicon wafer, and the method includes the following steps: using a laser 1 with a pulse width ranging from picoseconds to femtoseconds and a laser wavelength of 1550 nm; The focused laser beam 5 generated by the laser 1 performs laser modification layer by layer from the lower surface to the upper surface of the silicon wafer. The modified focus position is realized by the high-precision Z-axis lifting table 4 driving the microscopic objective lens 3. The corresponding movement trajectories of different focus positions It is calculated and generated by the control system 8 and realized by controlling the XY linear motor 7; by setting the laser cutting speed, PSO laser point spacing, and laser single pulse size to control the processing depth of each layer from S1 to ...

Embodiment 2

[0092] Please also refer to figure 2 with Figure 9 , Figure 10 , the present embodiment provides a method for machining three-dimensional contours of glass, wherein the transparent material workpiece 6 is made of glass, and the method includes the following steps: using a laser 1 with a pulse width ranging from picoseconds to femtoseconds and a laser wavelength of 1030-1080nm; The focused laser beam 5 generated by the laser 1 performs laser modification layer by layer from the lower surface to the upper surface of the glass. The modified focus position is realized by the high-precision Z-axis lifting table 4 driving the microscopic objective lens 3. The movement trajectory corresponding to different focus positions is determined by The control system 8 calculates and generates, and realizes by controlling the XY linear motor 7; by setting the laser cutting speed, PSO laser point spacing, and laser single pulse size to control the processing depth of each layer from G1 to G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com