Plastic floor and preparation method thereof

A technology of plastic flooring and stone plastic, applied in the direction of chemical instruments and methods, lamination, building components, etc., can solve the problems of large shrinkage rate and expansion rate, poor stability, etc., to improve stability, reduce product thickness, and accurately The effect of product thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

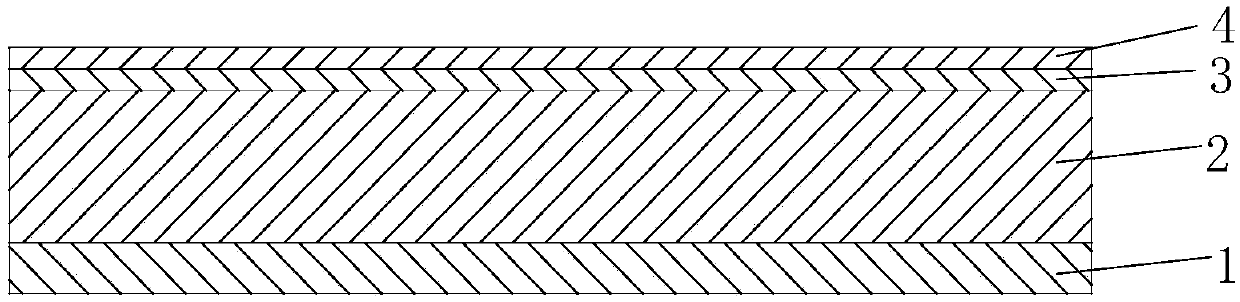

[0027] A plastic floor, comprising a sound-absorbing layer, a stone-plastic substrate layer, a color film layer and a wear-resistant layer arranged sequentially from bottom to top. Wherein, the material of the quiet layer is irradiated cross-linked polyethylene foam material, and its thickness is 1.0mm. The thickness of the stone-plastic substrate layer is 1.0 mm. The thickness of the color filter layer is 0.07mm. The thickness of the wear-resistant layer is 0.07mm. The stone-plastic substrate layer is made of the following raw materials in parts by weight: 50 parts of polyvinyl chloride, 100 parts of calcium carbonate, 6 parts of calcium-zinc composite stabilizer, 0.7 part of stearic acid, 0.5 part of polyethylene wax, acrylate 3 parts of polymer, 3 parts of chlorinated polyethylene.

[0028] The plastic floor is prepared by the following method:

[0029] According to the formula of the stone-plastic base material layer, mix the raw materials of the stone-plastic base mat...

Embodiment 2

[0033] A plastic floor, comprising a sound-absorbing layer, a stone-plastic substrate layer, a color film layer and a wear-resistant layer arranged sequentially from bottom to top. Wherein, the material of the quiet layer is irradiated cross-linked polyethylene foam material, and its thickness is 1.5 mm. The thickness of the stone-plastic substrate layer is 2.0mm. The thickness of the color filter layer is 0.07mm. The thickness of the wear-resistant layer is 0.13mm. The stone-plastic substrate layer is made of the following raw materials in parts by weight: 50 parts of polyvinyl chloride, 110 parts of calcium carbonate, 6 parts of calcium-zinc composite stabilizer, 0.7 part of stearic acid, 0.6 part of polyethylene wax, acrylate 4 parts of polymer, 4 parts of chlorinated polyethylene.

[0034] The plastic floor is prepared by the following method:

[0035] According to the formula of the stone-plastic base material layer, mix the raw materials of the stone-plastic base mat...

Embodiment 3

[0039]A plastic floor, comprising a sound-absorbing layer, a stone-plastic substrate layer, a color film layer and a wear-resistant layer arranged sequentially from bottom to top. Wherein, the material of the quiet layer is irradiated cross-linked polyethylene foam material, and its thickness is 1.5mm. The thickness of the stone-plastic substrate layer is 3.0 mm. The thickness of the color filter layer is 0.07mm. The thickness of the wear-resistant layer is 0.13mm. The stone-plastic substrate layer is made of the following raw materials in parts by weight: 60 parts of polyvinyl chloride, 120 parts of calcium carbonate, 8 parts of calcium-zinc composite stabilizer, 0.8 part of stearic acid, 0.7 part of polyethylene wax, acrylate 4 parts of polymer, 4 parts of chlorinated polyethylene.

[0040] The plastic floor is prepared by the following method:

[0041] According to the formula of the stone-plastic base material layer, mix the raw materials of the stone-plastic base mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com