Preparation method of titanium alloy plate

A technology of titanium alloy and plate, which is applied in the field of preparation of titanium alloy plate, can solve the problems of high equipment and operation requirements, small specific heat capacity of titanium alloy, high resistance to processing deformation, etc., achieve efficient and stable production, shorten production cycle, size The effect of precision optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

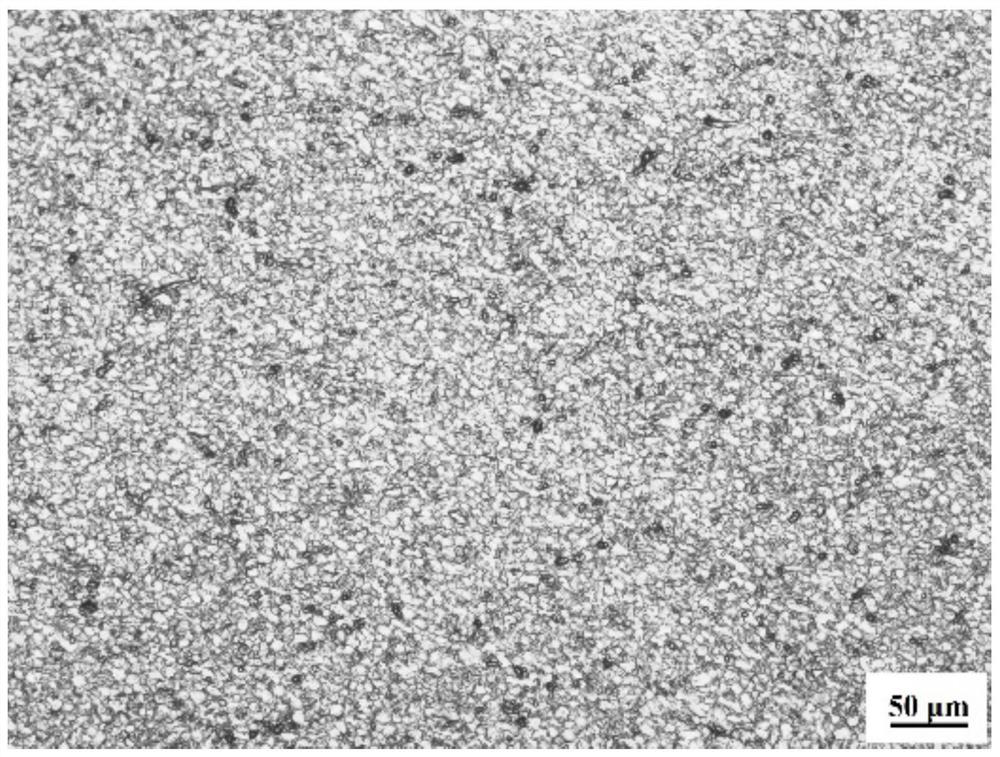

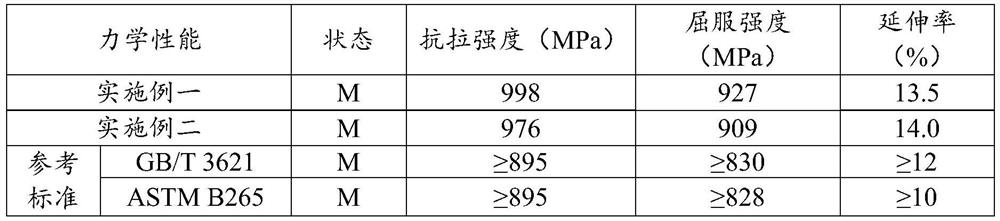

Embodiment 1

[0060] Embodiment 1 of the present invention: a preparation method of a titanium alloy plate: comprising the following steps:

[0061] S1: The TC4 dual-phase titanium alloy large slab (160mm in thickness and 1100mm in width) was first kept warm at 970°C for 260min, and then hot-rolled to obtain TC4 titanium alloy hot-rolled coils with the required thickness; Rolling includes rough rolling and finishing rolling; the rough rolling method is: first roll the large slab to the intermediate billet, the rolling temperature of the intermediate billet is 930°C, and the thickness of the intermediate billet is 42mm; the finishing rolling method is: pass through 7 stands The thickness of the intermediate billet is rolled to 4.5mm, and the exit temperature of the finish rolling is 830°C.

[0062] S2: heat the TC4 titanium alloy hot-rolled coil at about 1000° C. for 18 minutes, force water cooling to 75° C., and coil to obtain a TC4 titanium alloy coil.

[0063] S3: The TC4 titanium alloy ...

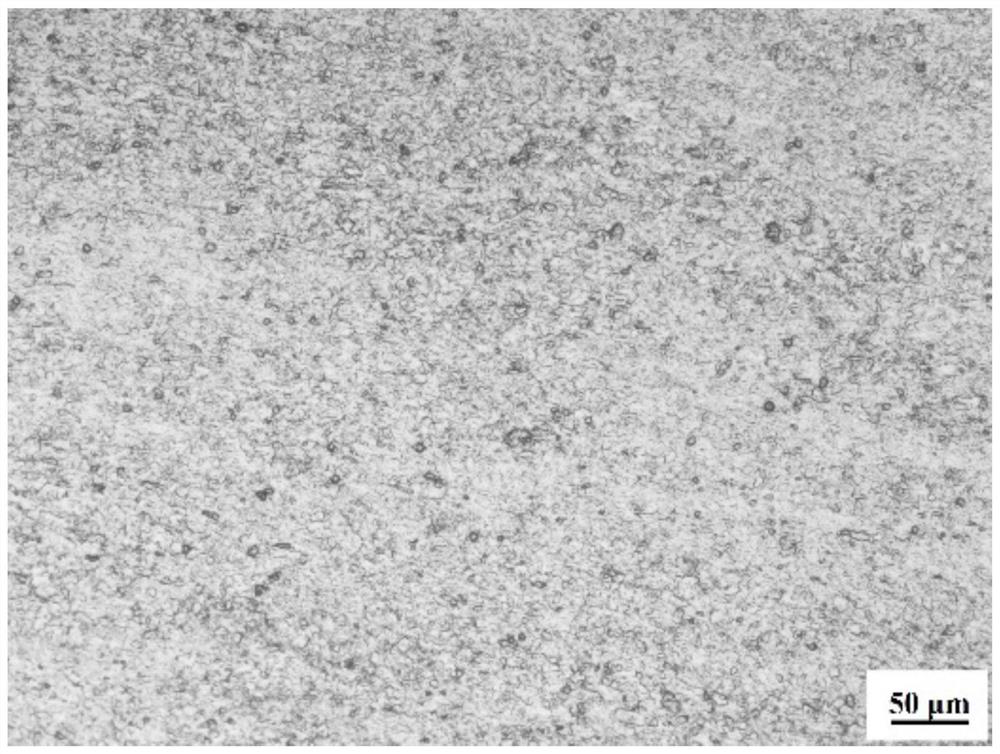

Embodiment 2

[0069] Embodiment 2 of the present invention: a preparation method of a titanium alloy plate: comprising the following steps:

[0070] S1: Gr.38 titanium alloy large slabs (thickness 165mm, width 1150mm) were first kept at 950°C for 280min, and then hot rolled to obtain Gr.38 titanium alloy hot-rolled coils with the required thickness; Continuous rolling includes rough rolling and finishing rolling; the rough rolling method is: firstly roll the large slab to the intermediate billet, the rolling temperature of the intermediate billet is 900°C, and the thickness of the intermediate billet is 48mm; the finishing rolling method is: through 7 stands The thickness of the intermediate billet was rolled to 6.0mm, and the exit temperature of the finish rolling was 810°C.

[0071] S2: heat the hot-rolled Gr.38 titanium alloy coil at about 965°C for 22 minutes, force water cooling to 68°C, and coil to obtain a Gr.38 titanium alloy coil.

[0072] S3: The Gr.38 titanium alloy coil is firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com