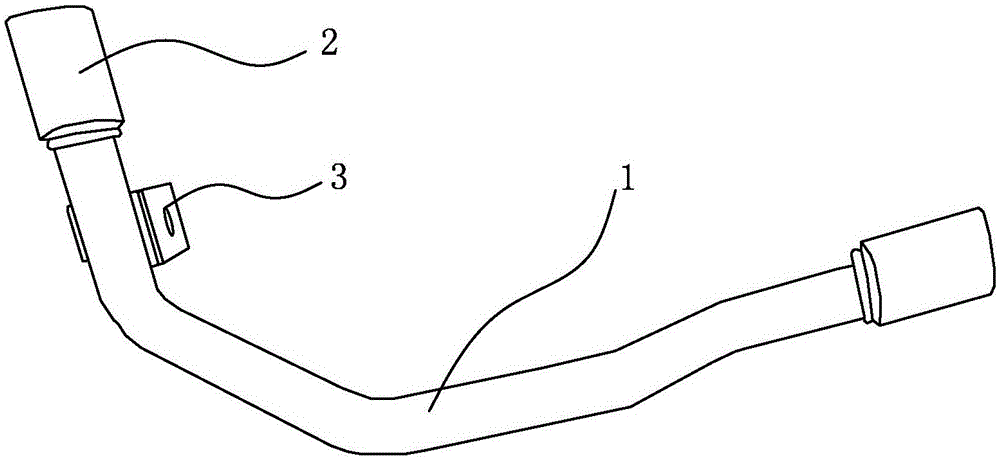

Surface treatment process for cooling water pipe joint assembly

A technology for surface treatment and cooling water pipes, which is applied in metal material coating process, superimposed layer plating, coating, etc. It can solve the problems of easy leakage of medium in the pipe, reduction of pressure bearing capacity, damage of plastic cooling water pipes, etc., and achieve improvement Decorative appearance, improved anti-discoloration ability, and improved anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

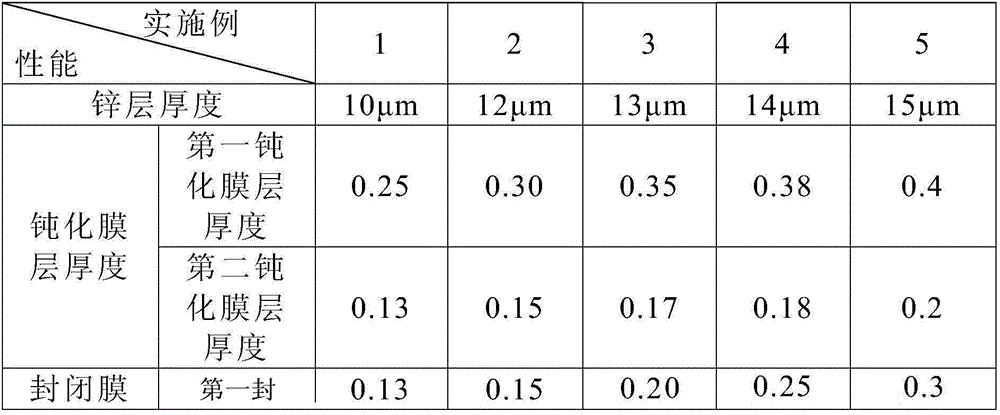

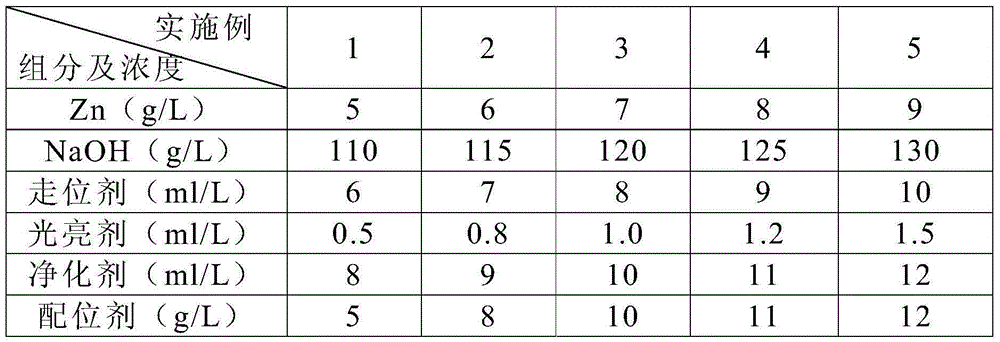

Embodiment 1

[0058] The cooling water pipe joint assembly blank made of iron material is firstly subjected to chemical degreasing and ultrasonic degreasing. The composition and concentration of the chemical degreasing solution are: Presol1700:70ml / L; the temperature of chemical degreasing is 50°C, and the time 10min. The composition and concentration of the ultrasonic degreasing solution are: COVENPREP121: 15g / L; the temperature of ultrasonic degreasing is 50°C, and the time is 5min. Then enter the initial electrolytic cell for initial electrolysis. The composition and concentration of the initial electrolytic electrolyte are: Presol7061: 70g / L; the current density of electrolysis is 1A / dm 2 , the electrolysis temperature is 50°C, and the electrolysis time is 5min. After the initial electrolysis, wash with water once, the flow rate is 200L / h, and the time is 10s. After washing with water, pickle with 25% hydrochloric acid for 10 minutes. After pickling, wash with water again, the flow r...

Embodiment 2

[0062] The cooling water pipe joint assembly blank made of iron material is firstly subjected to chemical degreasing and ultrasonic degreasing. The composition and concentration of the chemical degreasing solution are: Presol1700:75ml / L; the temperature of chemical degreasing is 55°C, and the time 12min. The composition and concentration of the ultrasonic degreasing solution are: COVENPREP121: 18g / L; the temperature of ultrasonic degreasing is 55°C, and the time is 6min. Then enter the initial electrolytic cell for initial electrolysis. The composition and concentration of the initial electrolytic electrolyte are: Presol7061: 75g / L; the current density of electrolysis is 2A / dm 2 , the electrolysis temperature is 55°C, and the electrolysis time is 5min. After the initial electrolysis, wash with water once, the flow rate is 200L / h, and the time is 10s. After washing with water, pickle with 28% hydrochloric acid for 12 minutes. After pickling, carry out two washings with water...

Embodiment 3

[0066] The cooling water pipe joint assembly blank made of iron material is firstly subjected to chemical degreasing and ultrasonic degreasing. The composition and concentration of the chemical degreasing solution are: Presol1700:80ml / L; the temperature of chemical degreasing is 60°C, and the time It is 13min. The composition and concentration of the ultrasonic degreasing solution are: COVENPREP121: 20g / L; the temperature of ultrasonic degreasing is 60°C, and the time is 5min. Then enter the initial electrolytic cell for initial electrolysis. The composition and concentration of the initial electrolytic electrolyte are: Presol7061: 80g / L; the current density of electrolysis is 3A / dm 2 , the electrolysis temperature is 60°C, and the electrolysis time is 6min. After the initial electrolysis, wash with water twice, with a flow rate of 160L / h for 10s each time. After washing with water, pickle with 30% hydrochloric acid for 13 minutes. After pickling, wash with water again, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thick bottom | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com