Environment-friendly ecological board and production process thereof

A production process and ecological board technology, which is applied in the field of board production, can solve problems such as wave patterns, carbonized bright spots, bubbling, poor brightness of the product board surface, step marks on the substrate surface, etc., and achieve formaldehyde-free environmental protection. Adhesive strength, The effect of improving flatness and improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

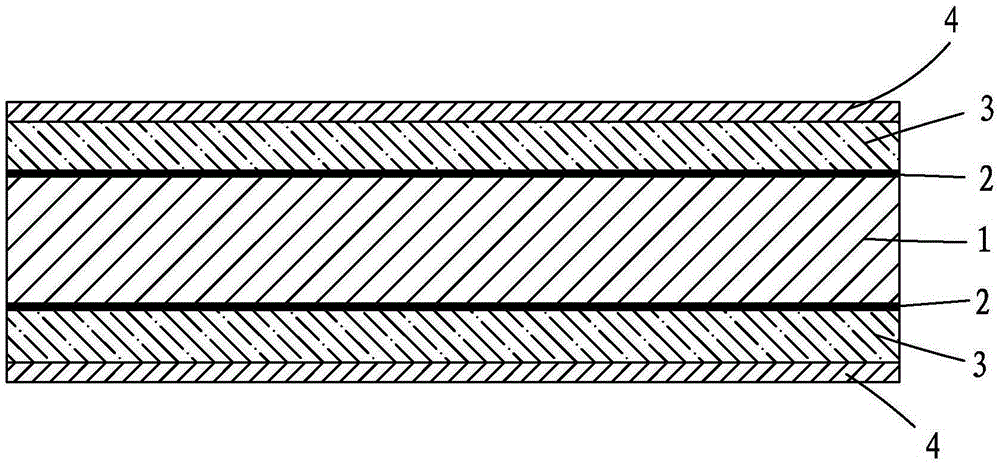

[0020] A production process of an environmentally friendly ecological board, comprising the steps of:

[0021] Step 1: Hot-press glue one side of the three-layer plywood and melamine-impregnated paper to form a melamine-impregnated paper-faced wood-based panel, let it cool down to room temperature, and wait for use; the duration of hot-pressing is 8 minutes, and the temperature is 125°C-130°C. Pressure 0.7MPa.

[0022] In practice, the duration of hot pressing in this step can be in the range of 5-15 minutes, the temperature can be between 100°C-150°C, and the pressure can be between 0.3-1.5MPa.

[0023] Step 2: Apply cold pressing glue on both sides of the substrate, and cold press with the melamine-impregnated paper-faced wood-based panel obtained in the above step 1; wherein the cold pressing glue is a water-based isocyanate adhesive, which is adjusted according to the following ratio: isocyanate adhesive 80%, curing agent 10%, flour 10%. The duration of cold pressing is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com