Manufacturing method of abrasion resistant transmission connecting rod assembly of automobile turbocharger

A transmission connecting rod and turbocharging technology, applied in connecting rods, vehicle parts, engine components, etc., can solve the problems of low material utilization and production efficiency, unstable quality, low mold life, etc., and achieve low processing cost, The effect of high material utilization rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

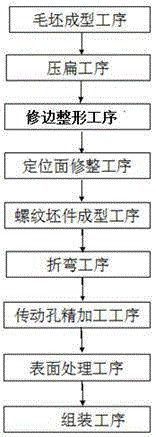

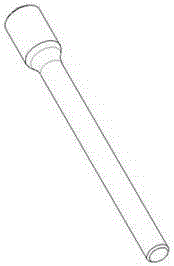

[0028] Such as Figure 1 to Figure 10 As shown, the manufacturing method of the automobile turbocharger wear-resistant transmission connecting rod assembly of the present invention comprises the following steps:

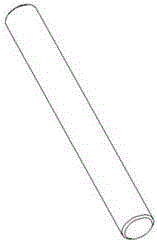

[0029] Step 1, blank forming process, step 1 adopts cold heading process or machining blanking and then cold heading and forming to form a wear-resistant transmission connecting rod blank, which is an automobile turbocharged wear-resistant transmission connecting rod blank. The outer diameter, length, structure, etc. of the blank are converted according to the total volume of the designed product. According to the theoretical volume, 5~10% of the trimming allowance is added to form a cylindrical or stepped cylindrical blank. The utilization rate of materials is high, which can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com