Preparation method of ultrathin adiabatic and insulated flexible non-woven fabrics resistant to 1000 degrees

A non-woven fabric and thermal insulation technology, which is applied in the direction of non-woven fabrics, textiles, papermaking, fiber types, etc., can solve the problems of continuous production, long-term use, and burnt supports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

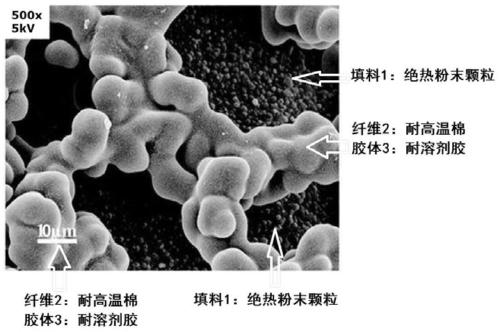

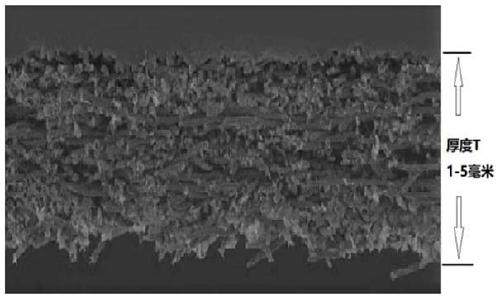

[0035] A preparation method of ultra-thin 1000°C heat-insulating flexible non-woven fabric, comprising the following steps,

[0036] S1) The non-metallic crystal minerals are melted and purified at a high temperature of 1500 ° C, and rare metal zirconium compounds (mass concentration 1.0%) and metal lithium compounds (mass concentration 0.3%) are added, and the diameter is 7 μm and the length is 4 mm. Grade glass fiber, which can be formed into high temperature resistant fiber;

[0037] S2) combing the high temperature resistant fiber into a thin cotton web with a uniform thickness of 2 mm by physical opening;

[0038] S3) Apply the solvent-resistant glue stock solution on the thin cotton net by the gravure transfer coating method. The solvent-resistant glue stock solution is compounded by water-based epoxy-modified polyurethane resin and soft water. The mass solubility of the two is 50% and 50% respectively. The amount of glue is 6%. After high temperature reaction, the orig...

Embodiment 2

[0042] A preparation method of ultra-thin 1000°C heat-insulating flexible non-woven fabric, comprising the following steps,

[0043] S1) The non-metallic crystal minerals are melted and purified at a high temperature of 1500°C, and rare metal titanium compounds (mass concentration 0.5%) and metal molybdenum compounds (mass concentration 0.3%) are added, and the fiber diameter is 11 μm and the length is 6 mm. Basalt fiber can be formed into high temperature resistant fiber;

[0044] S2) combing the high temperature resistant fiber into a thin cotton web with a uniform thickness of 5mm by physical opening;

[0045] S3) Apply the solvent-resistant glue stock solution on the thin cotton net by flat padding method. The solvent-resistant glue stock solution is compounded by water-based butadiene rubber, water-based silicone rubber and soft water. The mass solubility of the three is respectively 10%, 25% and 65%, the sizing amount is 10%, the glue stock solution is polymerized into ...

Embodiment 3

[0049] A preparation method of ultra-thin 1000°C heat-insulating flexible non-woven fabric, comprising the following steps,

[0050] S1) The non-metallic crystal minerals are melted and purified at a high temperature of 1500°C, and rare metal zirconium compounds (mass concentration 1.0%) and metal lithium compounds (mass concentration 0.3%) are added, and the S grade with a diameter of 7 μm and a length of 4 mm is produced by centrifugal spinning method Glass fibers and silica fibers with a diameter of 9 μm and a length of 6 mm are mixed to form a high-temperature-resistant fiber composite material according to the fiber weight ratio of 50% and 50%;

[0051] S2) Carding the high temperature resistant fiber composite material into a thin cotton web with a uniform thickness of 3 mm by physical opening;

[0052] S3) The solvent-resistant glue stock solution is applied on the thin cotton net by vacuum suction method, and the solvent-resistant glue stock solution is compounded by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com