Single-roller type shearing tool

A technology of cutting blades and knives, which is applied in the manufacture of tools, wood processing equipment, thin wood chips, etc., can solve the problems of large thickness tolerance of cut products, high cost, and affecting product quality, so as to reduce production costs and divide The effect of high cutting efficiency and improving the utilization rate of bamboo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

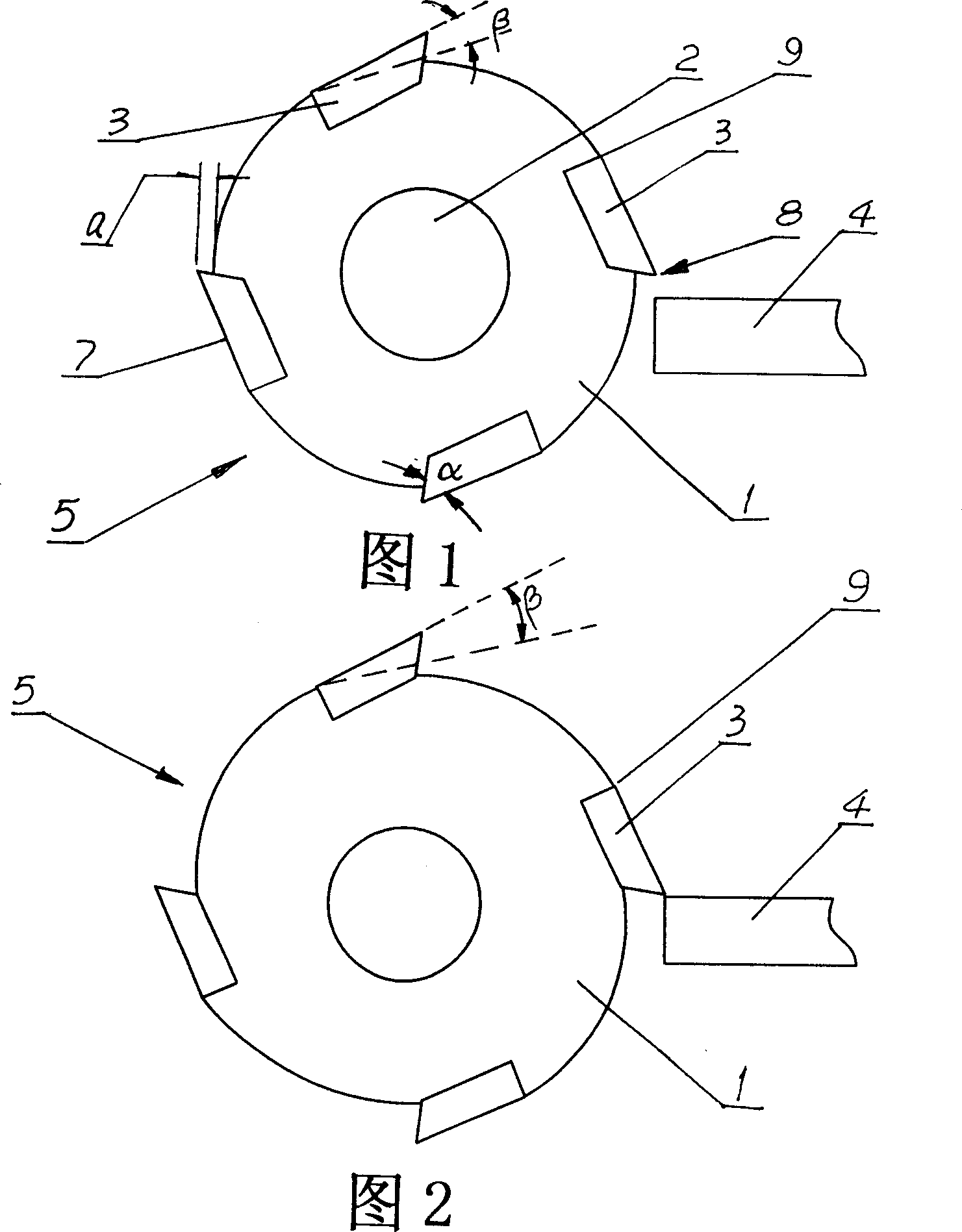

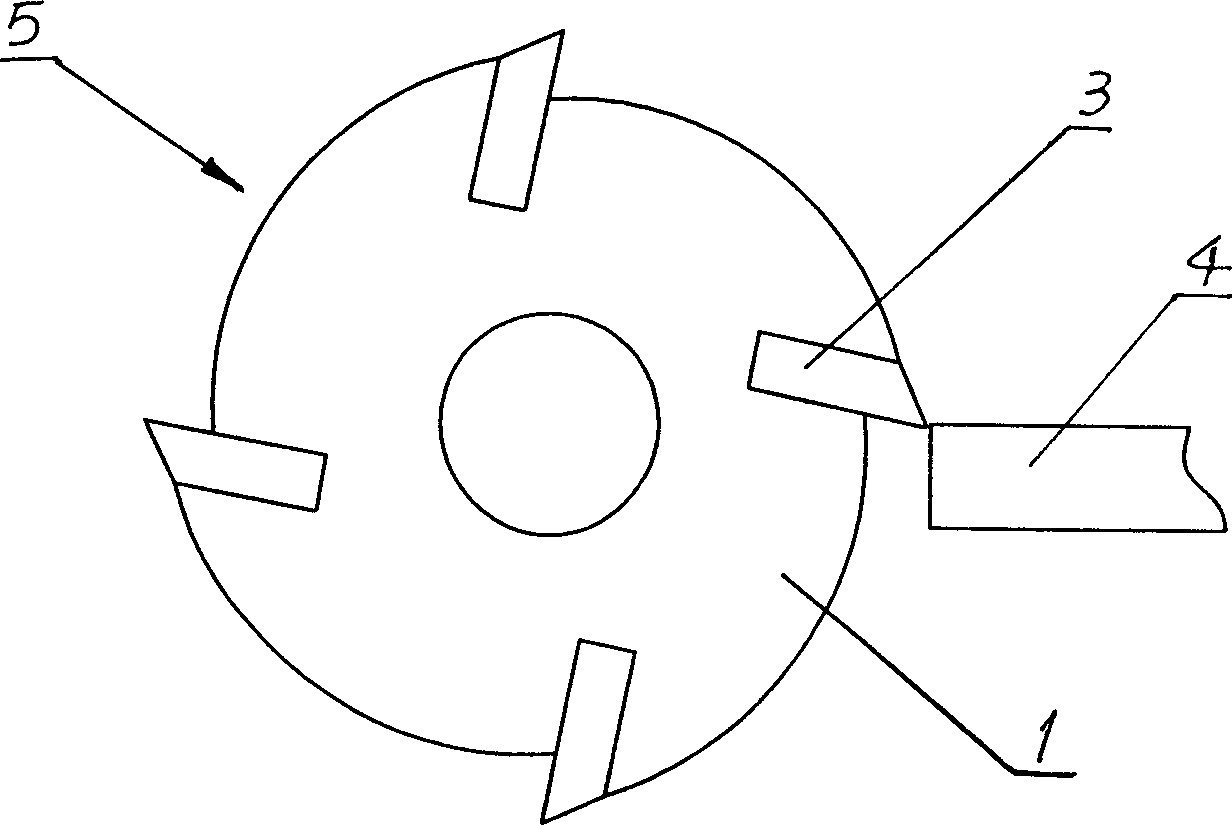

[0023] Example 1: According to the single-roll shear cutter of the present invention according to Figures 1 and 6 and the above-mentioned structure, the diameter and length of the roller body 1 are respectively 300mm and 3000mm or 200mm and 1300mm; the cutting edge line of the shearing blade 3 is 8 to The distance a from the surface of the roller body 1 (ie, the thickness of the cut product) is adjustable from 1-4 mm. The four shearing blades 3 are evenly distributed on the surface of the roller body 1. The surface of the roller body 1 is smoothly curved to the surface 7 of the shearing blade 3 The trailing edge 9 is smoothly connected, and the design speed of the roller body 1 is 40-300rpm.

Embodiment 2

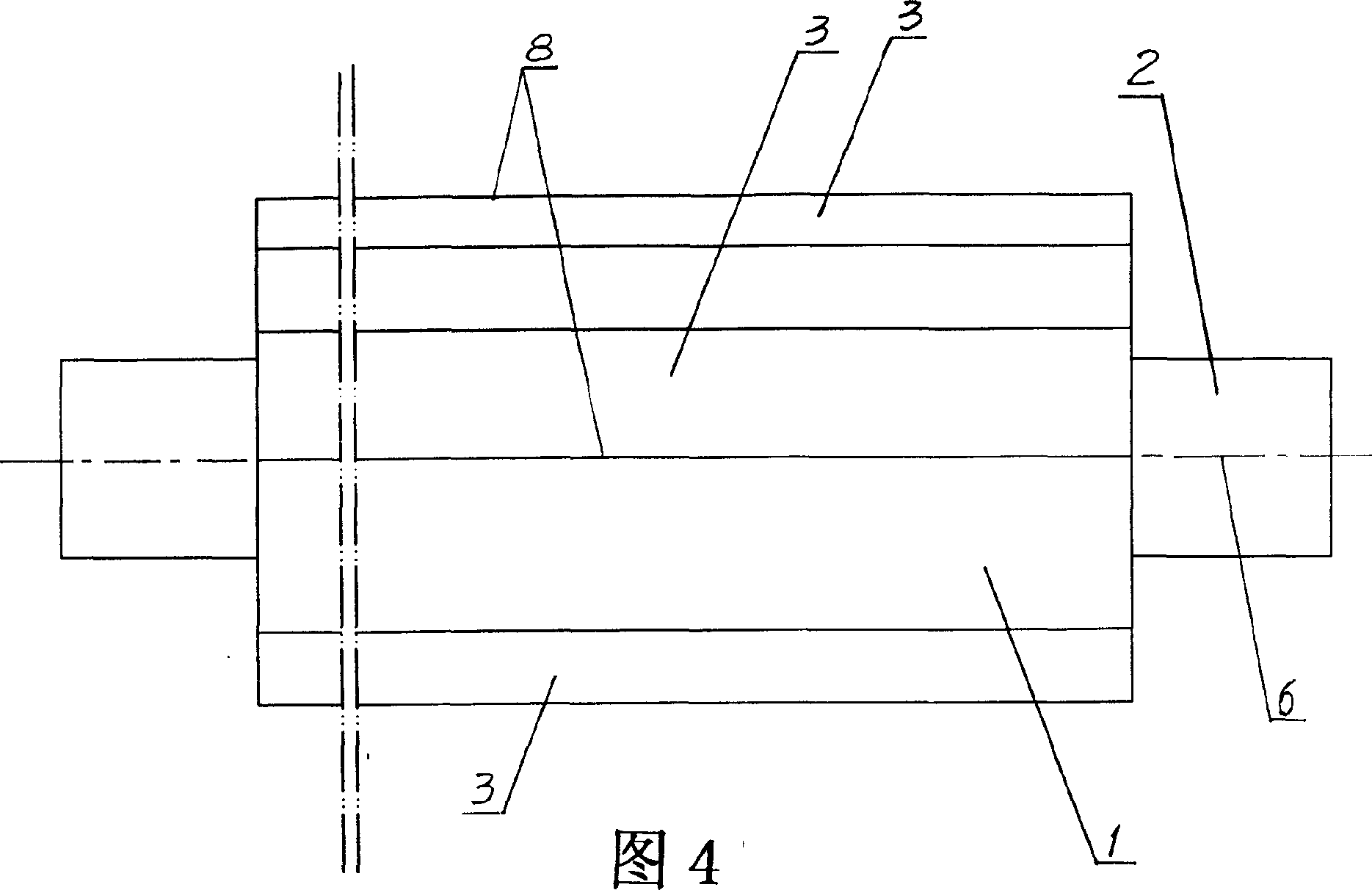

[0024] Embodiment 2: Referring to FIG. 7, the roller body 1 is composed of five single rollers 10 mounted on the roller shaft 2, and the corresponding shearing blade 3 is installed in the unit of each single roller 10 to form the structure shown in FIG. 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com