Heat-conducting insulating composite material and preparation method thereof

A composite material, heat conduction and insulation technology, applied in the direction of coating, etc., to achieve good thermal conductivity and insulation, reduce waste, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

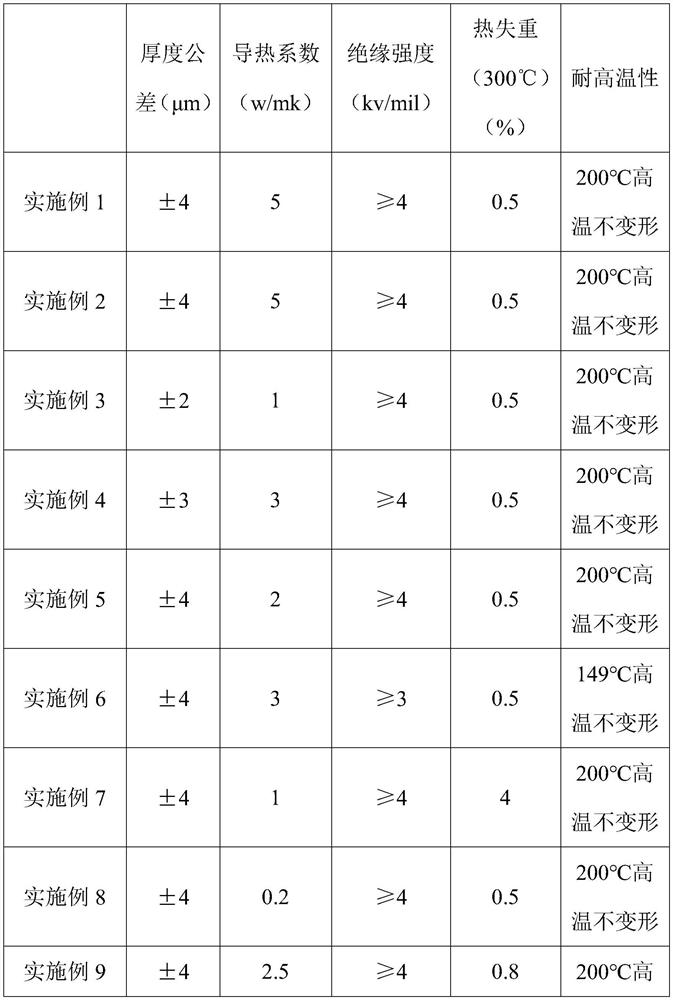

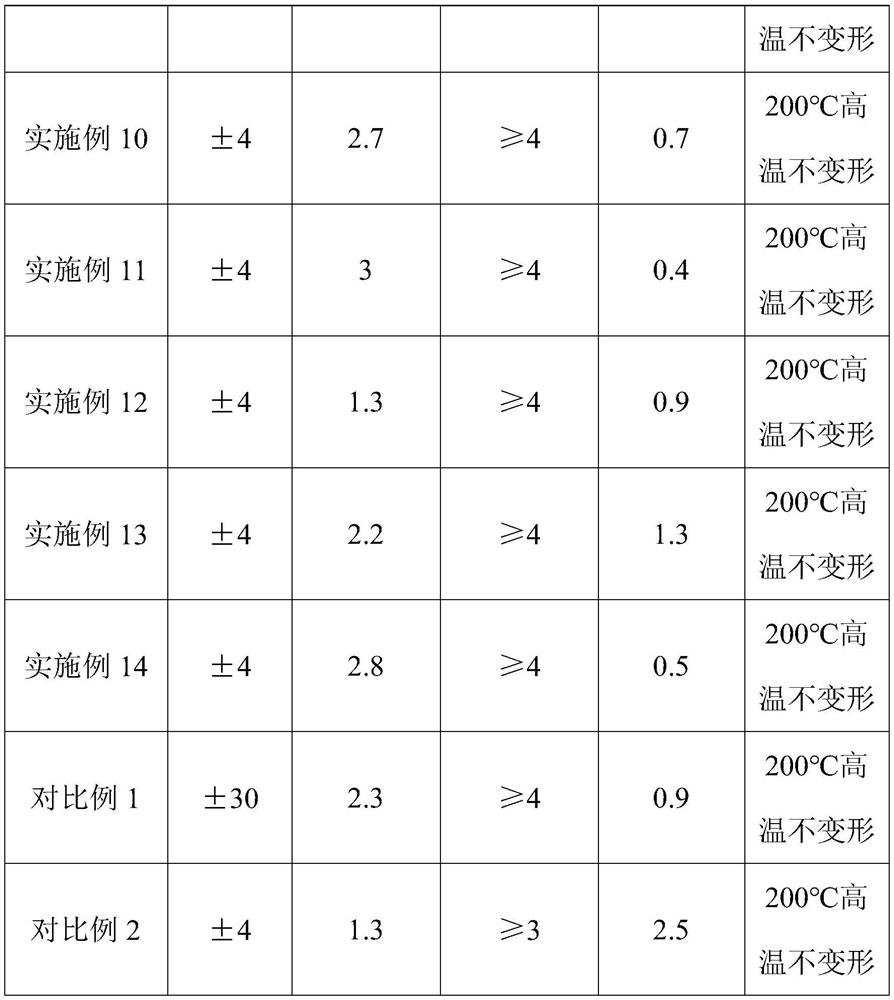

Examples

Embodiment 1

[0065] The present embodiment provides a preparation method of a thermally conductive and insulating composite material, which includes the following steps:

[0066] (1) Unwind the polyimide film to the coating head of the coating equipment, and evenly coat the thermally conductive silicone rubber on one side of the insulating film;

[0067] (2) The insulating film coated in step (1) is transported into an oven to be fully baked, and is wound up after leaving the oven.

[0068] Among them, the coating process is blade coating, the blade is a comma blade; the coating speed is 5m / min; the minimum gap between the comma blade and the coating roller of the coating equipment is 0.02mm.

[0069] The preparation raw materials of thermally conductive silicone rubber include A component and B component, and the mass ratio of A component and B component is 1:1. By mass percentage, component A includes 15% vinyl polysiloxane, 80% thermally conductive filler alumina, 100ppm platinum catal...

Embodiment 2

[0074] The present embodiment provides a preparation method of a thermally conductive and insulating composite material, which includes the following steps:

[0075] (1) After the polyimide film is treated with corona and sticky dust, it is unwound to the coating head of the coating equipment, and the thermally conductive silicone rubber is evenly coated on one side of the insulating film;

[0076] (2) The insulating film coated in step (1) is transported into an oven to be fully baked, and is wound up after leaving the oven.

[0077] Among them, the coating process is scraping, and the scraper is a comma scraper; the coating speed is 5m / min; the minimum gap between the comma scraper and the coating roller of the coating equipment is 0.02mm;

[0078] The preparation raw materials of thermally conductive silicone rubber include A component and B component, and the mass ratio of A component and B component is 1:1. By mass percentage, component A includes 15% vinyl polysiloxane,...

Embodiment 3

[0083] The present embodiment provides a preparation method of a thermally conductive and insulating composite material, which includes the following steps:

[0084] (1) After the polyimide film is treated with corona and sticky dust, it is unwound to the coating head of the coating equipment, and the thermally conductive silicone rubber is evenly coated on both sides of the insulating film;

[0085] (2) The insulating film coated in step (1) is transported into an oven to be fully baked, and is wound up after leaving the oven.

[0086] Among them, the coating process is scraping, and the scraper is a comma scraper; the coating speed is 10m / min; the minimum gap between the comma scraper and the coating roller of the coating equipment is 0.05mm;

[0087] The preparation raw materials of thermally conductive silicone rubber include A component and B component, and the mass ratio of A component and B component is 1:1. By mass percentage, component A includes 15% vinyl polysiloxa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com