Cold drawing, cold rolling production method for high-accuracy weldless steel tube

A technology for seamless steel pipes and production methods, applied in the direction of high-frequency current welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of low weld strength, inability to eliminate weld traces, high production costs, etc., and achieve uniform wall thickness, The effect of low cost and high operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

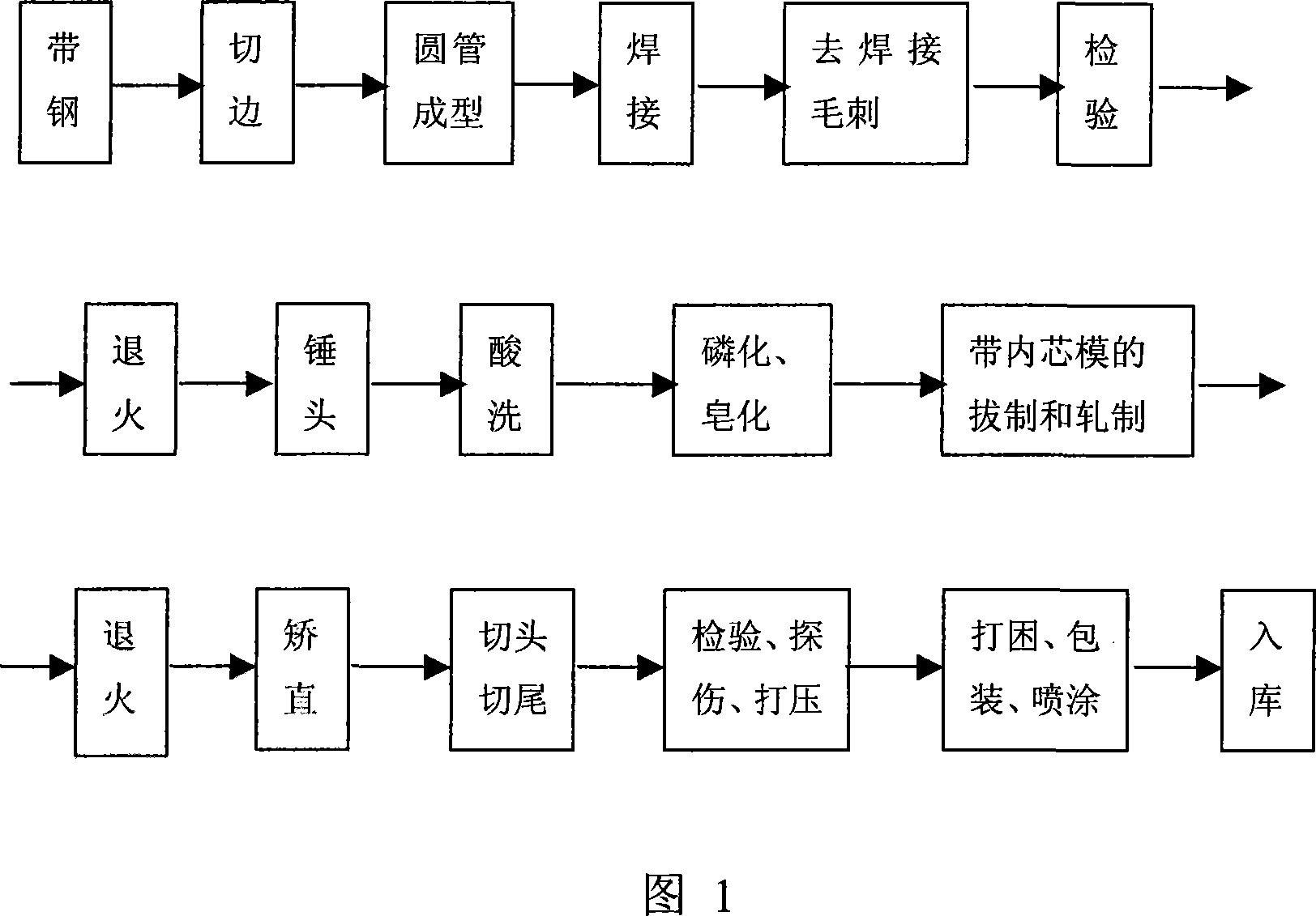

[0023] Referring to Fig. 1, the cold drawing and cold rolling process of the present invention include steps: trimming the edges of the raw material strip steel, round tube forming (the strip steel is formed into a round tube shape on a deformation machine), welding (after adopting a high-frequency welded pipe machine to weld and form round pipe), welding burr removal (to make the welded part flush with the pipe wall and smooth without steps), inspection, heating (heating temperature is 950°C±50°C, time 20-30 minutes), hammer head, pickling, phosphorus Saponification and saponification (lubricating layer), drawing or rolling with an inner mandrel (the welded pipe after heating, hammering, and lubrication is passed through the outer die and inner mandrel of the cold drawing machine or the roll and inner mandrel of the cold rolling mill The drawing or rolling of the core and the extrusion of the inner core make it reduce the diameter, wall and extend. Generally, the diameter redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com