Grinding method for controlling roughness of surfaces of different rollers

A roll surface and roughness technology, applied in the field of roll grinding, to reduce costs, prolong online time, and improve plate shape and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention.

[0020] The type of grinding wheel used in this embodiment: P900*100*305SA80K8B50; the material of the ground roll is alloy forged steel, the diameter of the roll is Φ380-425mm, the length of the roll body is 1450mm, and the hardness of the roll is HS93-97. It is very important to choose a suitable grinding wheel according to the rolls of different materials and hardness. For rolls with high hardness, choose a relatively soft grinding wheel.

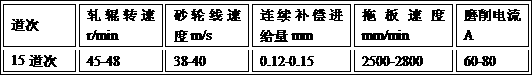

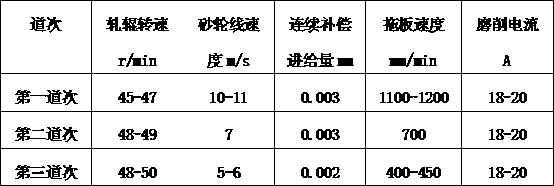

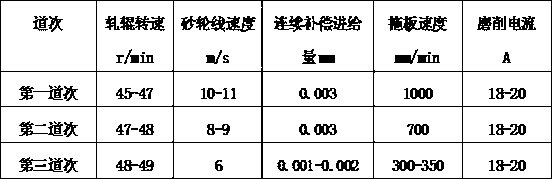

[0021] The grinding method of controlling the surface roughness of different rollers described in this embodiment, its steps are as follows:

[0022] ⑴ Grinding wheel dressing:

[0023] This step is to ensure the balance of the grinding wheel and the smoothness and fineness of the working surface of the grinding wheel. It is carried out according to the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com