Alloy steel support roll of rolling mill and manufacturing process thereof

A manufacturing process and support roll technology, which is applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of high and low wear resistance, and achieve the effect of high hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] One of embodiment of the present invention is a kind of alloy steel back-up roll of rolling mill, in the alloy steel back-up roll of this rolling mill, the alloy steel contains following composition: by weight percentage, the content of carbon (C) is 0.45%, silicon ( Si) content is 1.6%, manganese (Mn) content is 1.75%, chromium (Cr) content is 1.6%, molybdenum (Mo) content is 0.25%, nickel (Ni) content is 0.5%, vanadium ( The content of V) is 0.08%, the content of niobium (Nb) is 0.06%, and the content of sulfur (S) and phosphorus (P) is less than or equal to 0.025%.

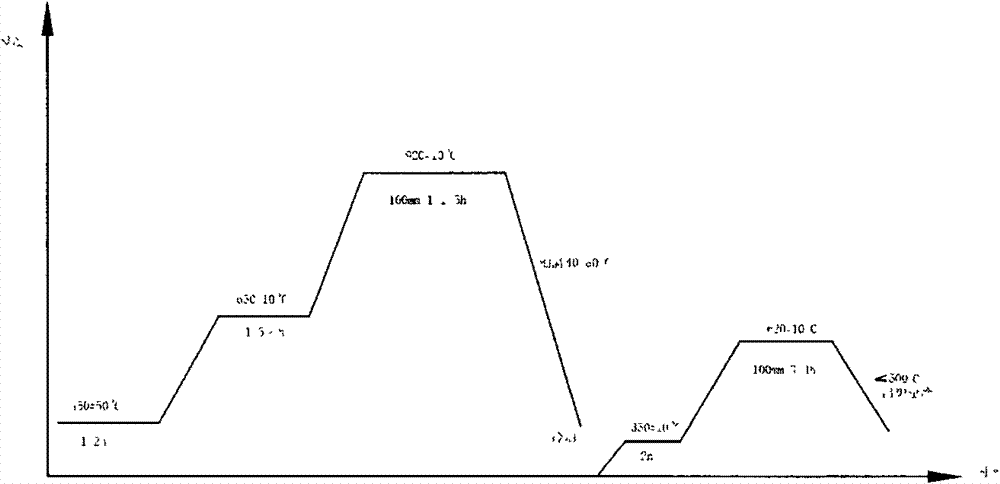

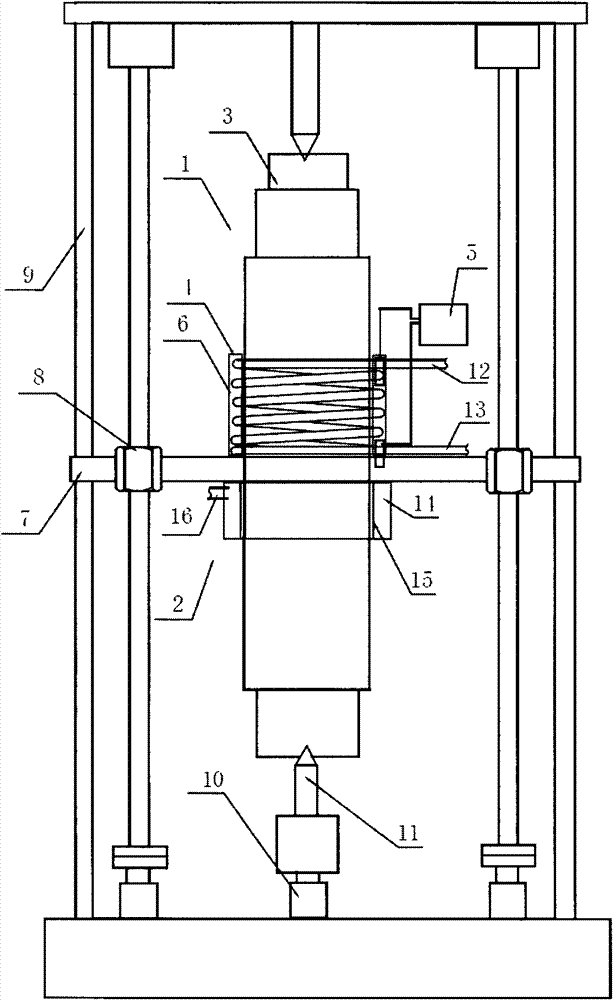

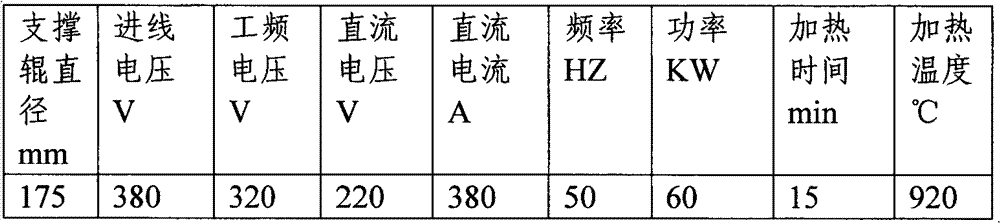

[0031] The technical solution of the present invention also provides a manufacturing process for producing alloy steel backup rolls of rolling mills using the above-mentioned alloy components. The manufacturing process includes a smelting process, a forging process and a heat treatment process. The process steps of the above-mentioned process are:

[0032] The first step: smelting process, the smelting p...

Embodiment 2

[0047] One of embodiment of the present invention is a kind of alloy steel back-up roll of rolling mill, contains following composition in the alloy steel back-up roll of this rolling mill: by weight percentage, the content of carbon (C) is 0.55%, silicon ( Si) content is 1.8%, manganese (Mn) content is 1.85%, chromium (Cr) content is 1.8%, molybdenum (Mo) content is 0.35%, nickel (Ni) content is 0.5%, vanadium ( The content of V) is 0.10%, the content of niobium (Nb) is 0.08%, and the content of sulfur (S) and phosphorus (P) is less than or equal to 0.025%.

[0048] The technical solution of the present invention also provides a manufacturing process for producing alloy steel backup rolls of rolling mills using the above-mentioned alloy components. The manufacturing process includes a smelting process, a forging process and a heat treatment process. The process steps of the above-mentioned process are:

[0049] The first step: smelting process, the smelting process adopts int...

Embodiment 3

[0059] One of embodiment of the present invention is a kind of alloy steel back-up roll of rolling mill, in the alloy steel back-up roll of this rolling mill, the alloy steel contains following composition: by weight percentage, the content of carbon (C) is 0.5%, silicon ( Si) content is 1.7%, manganese (Mn) content is 1.80%, chromium (Cr) content is 1.7%, molybdenum (Mo) content is 0.30%, nickel (Ni) content is 0.5%, vanadium ( The content of V) is 0.09%, the content of niobium (Nb) is 0.07%, the content of aluminum (Al) is 0.0225%, and the content of sulfur (S) and phosphorus (P) is less than or equal to 0.025%.

[0060] The technical solution of the present invention also provides a manufacturing process for producing alloy steel backup rolls of rolling mills using the above-mentioned alloy components. The manufacturing process includes a smelting process, a forging process and a heat treatment process. The process steps of the above-mentioned process are:

[0061] The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com