A control system for prolonging the service life of the soft roll surface in the roll nip

A technology of control system and soft roll, which is applied in the field of pressurization in the roll nip, can solve the problems of reducing production time, increasing maintenance workload, and prolonging equipment maintenance time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

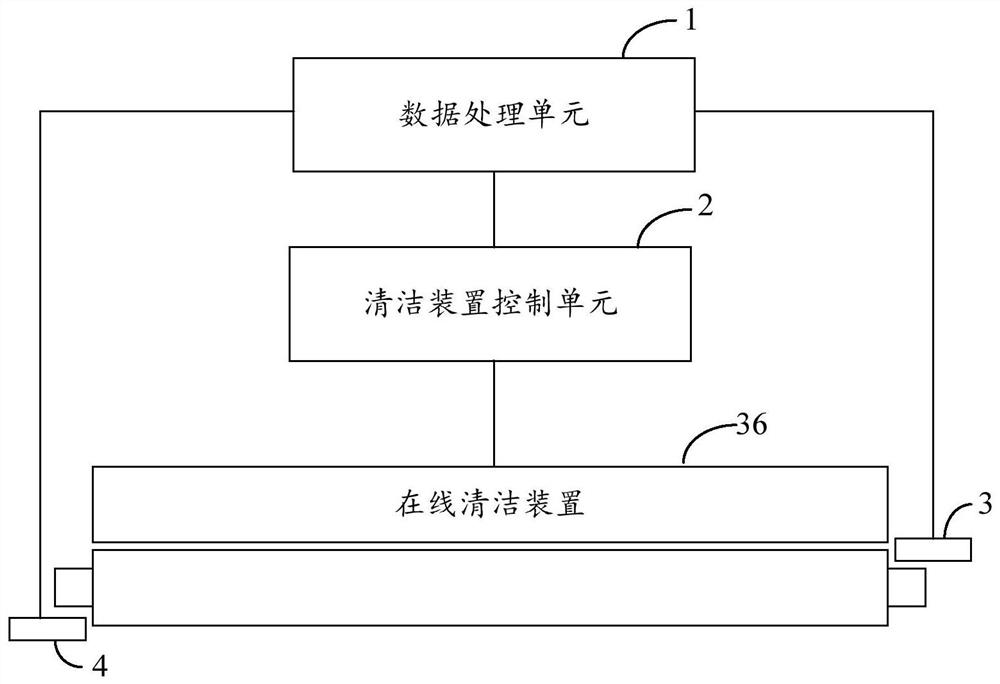

[0045] figure 1 It is a structural schematic diagram of the control system for prolonging the service life of the soft roll surface in the roll nip provided by the embodiment of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown in the figure.

[0046] The control system for extending the service life of the soft roll surface in the roll nip includes a data processing unit 1, a cleaning device control unit 2, and vibration sensors 3 and rotational speed sensors 4 arranged at both ends of the soft roll in the nip, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com