A self-adaptive working roll box of a tension leveling scale breaker

A work roll, self-adaptive technology, applied in the direction of manufacturing tools, metal rolling stands, metal rolling mill stands, etc., can solve the problems of serious wear, uneven deformation, increased frequency of roll change, etc., to reduce production operation cost, improving the state of contact force, reducing the effect of changing the frequency of rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

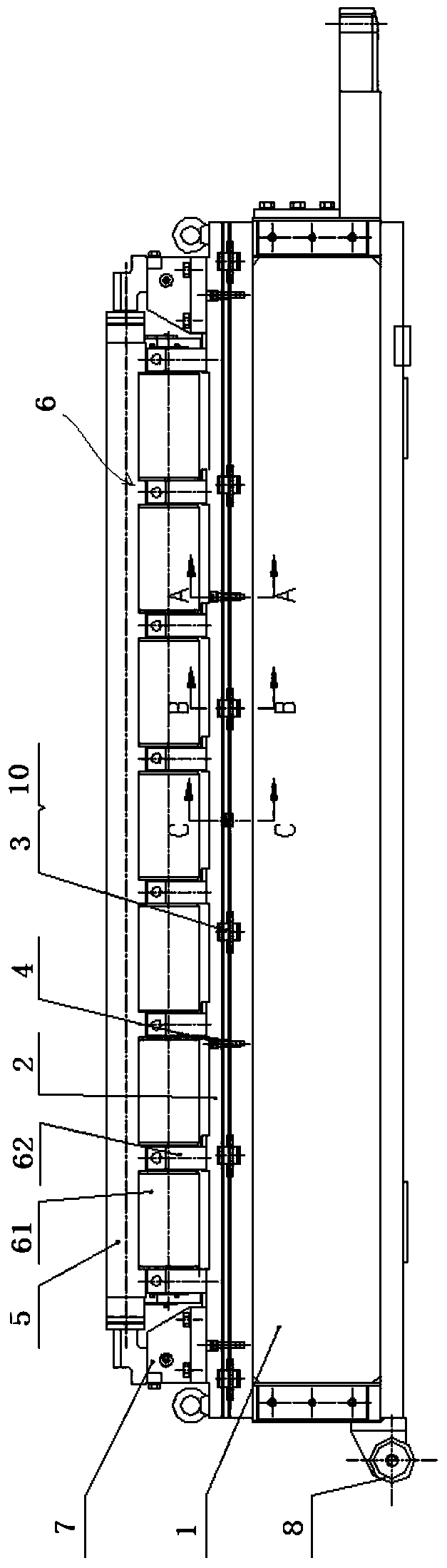

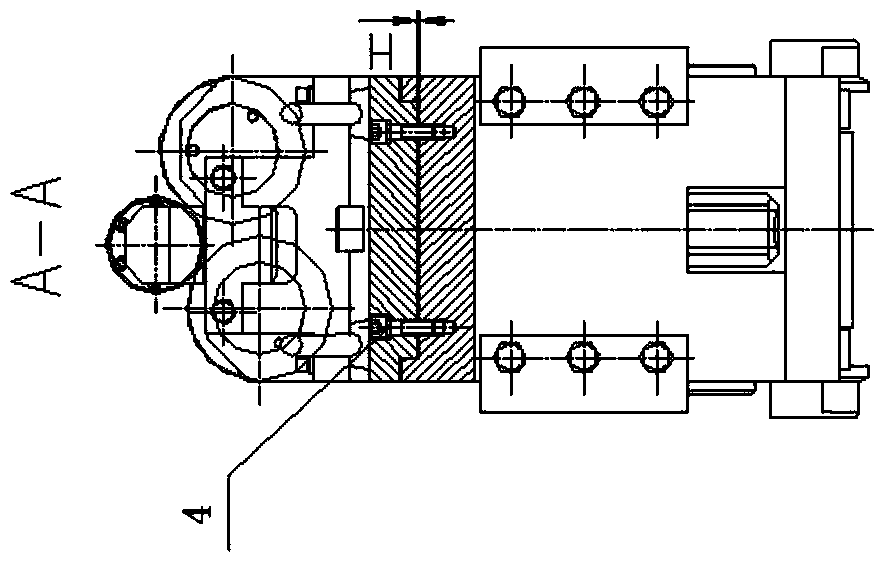

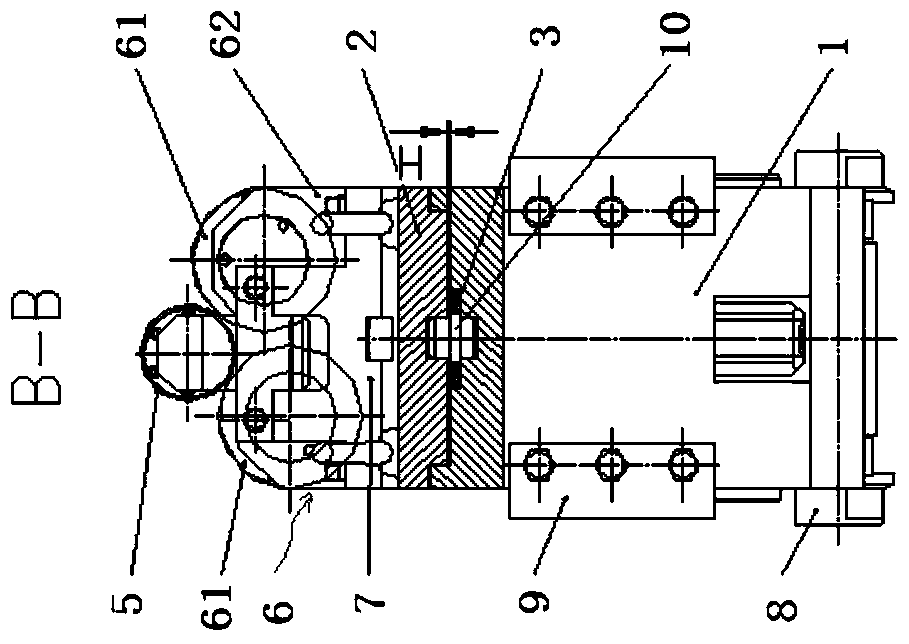

[0029] Such as Figure 1-4 As shown, the present invention provides a self-adaptive work roll box of a tension leveling scale breaker, comprising a roll box body, on which a work roll 5, a support roll assembly 6 for supporting the work roll 5, and a support roll assembly 6 for supporting the work roll 5 are provided on the roll box body. The anti-slip device 7 for preventing the axial shifting of the work roll 5 and the roller assembly 8 for the sliding of the roll box body, the roll box body includes a base I1 and a base II2 connected to the base I1 through a connecting piece, the base An elastic deformation mechanism is provided between I1 and base II2; the base I1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com