High carbon high-speed steel of containing granular carbide, and preparation method

A high-speed steel and carbide technology, applied in the field of metal material manufacturing, can solve the problems of low production efficiency, complicated process and equipment, and complicated process, and achieve the effect of improving the operation rate, improving the surface quality, and prolonging the roller changing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

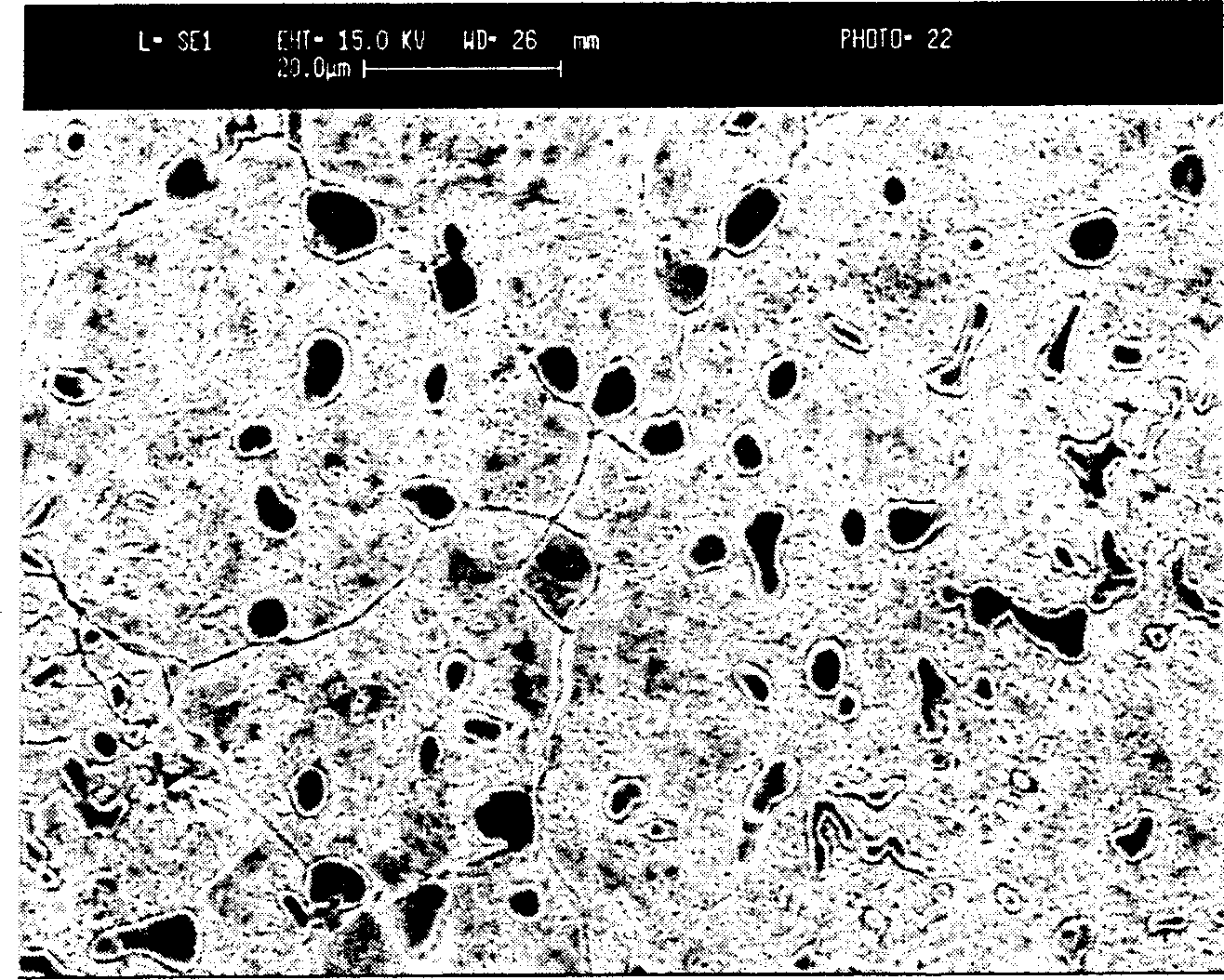

Image

Examples

Embodiment 1

[0035] Melting high-carbon high-speed steel with a 1000 kg alkaline intermediate frequency induction furnace, the manufacturing process steps are:

[0036] ①Heating and melting ordinary steel scrap, ferrotungsten, ferromolybdenum, ferrochromium, ferroniobium and pig iron, adding ferrovanadium after molten steel is melted;

[0037] ② After adjusting the composition before the furnace, the temperature is raised to 1610°C, adding 0.22% of the weight of molten steel for deoxidation, and then out of the furnace;

[0038] ③Crush the rare earth magnesium alloy, ferro-titanium, zinc-containing substances and nitrogen-containing substances into small pieces with a particle size of less than 15mm. After drying below 200°C, place them at the bottom of the ladle, and use the method of pouring into the ladle to compound the molten steel. deal with;

[0039] ④ After the molten steel has been stirred, left still and slag removed, the Φ380mm×1000mm roll is directly poured on the horizontal c...

Embodiment 2

[0044] Melting high-carbon high-speed steel with a 1000 kg alkaline intermediate frequency induction furnace, the manufacturing process steps are:

[0045] ①Heating and melting ordinary steel scrap, ferrotungsten, ferromolybdenum, ferrochromium, cobalt metal and pig iron, adding ferrovanadium after molten steel is melted;

[0046] ② After adjusting the composition before the furnace, the temperature is raised to 1590°C, adding 0.18% of the weight of molten steel for deoxidation of aluminum, and then out of the furnace;

[0047] ③Crush the rare earth magnesium alloy, ferro-titanium, zinc-containing substances and nitrogen-containing substances into small pieces with a particle size of less than 15mm. After drying below 200°C, place them at the bottom of the ladle, and use the method of pouring into the ladle to compound the molten steel. deal with;

[0048] ④ After the molten steel has been stirred, left still and slag removed, the Φ380mm×1000mm rolls are directly poured on th...

Embodiment 3

[0053] Melting high-carbon high-speed steel with a 500-kg neutral medium-frequency induction furnace, the manufacturing process steps are:

[0054] ①Heating and melting ordinary steel scrap, ferrotungsten, ferromolybdenum, ferrochromium, ferroniobium, cobalt metal and pig iron, adding ferrovanadium after molten steel is melted;

[0055] ② After adjusting the composition before the furnace, the temperature is raised to 1603°C, adding 0.14% of the weight of molten steel to deoxidize the aluminum, and then out of the furnace;

[0056] ③Crush the rare earth magnesium alloy, ferro-titanium, zinc-containing substances and nitrogen-containing substances into small pieces with a particle size of less than 15mm. After drying below 200°C, place them at the bottom of the ladle, and use the method of pouring into the ladle to compound the molten steel. deal with;

[0057] ④ After the molten steel has been stirred, left still and slag removed, the Φ350mm×600mm rolls are directly poured on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com