Ground remote control system for downhole electric locomotives

A remote control, electric locomotive technology, applied in electrical program control, comprehensive factory control, etc., can solve the problems of working environment, safety guarantee transportation efficiency restriction, human efficiency reduction, safety hidden danger, etc., to improve the level of intrinsic safety and improve the operation. rate, the effect of system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

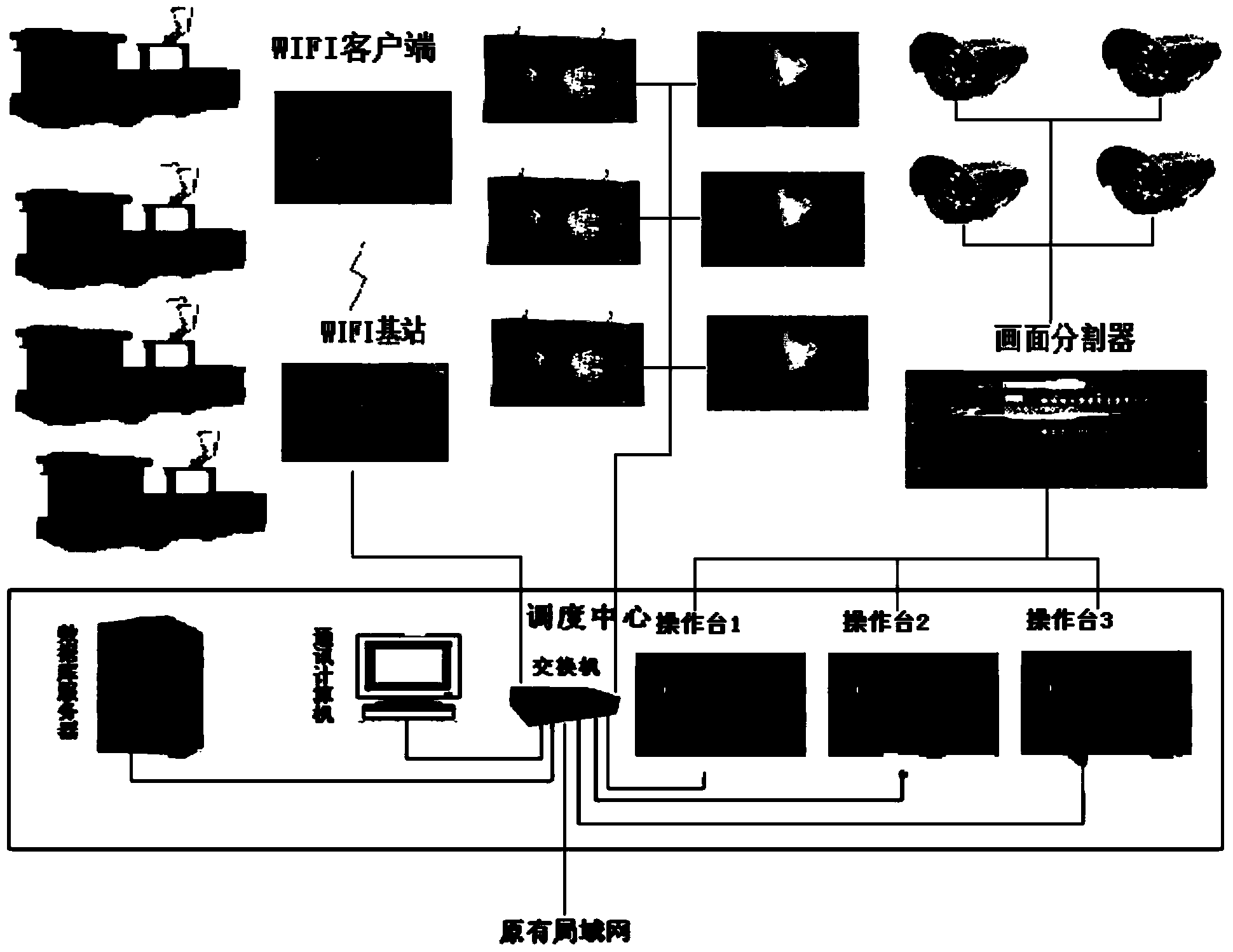

[0056] 1. Introduction to Xingshan Iron Mine of Shougang Mining Company

[0057] Xingshan Iron Mine is the first underground mining mine built by Shougang. The mining range of the first phase of Xingshan underground mining is determined to be above the level of -330m. The mine scale of the first phase project is 3.2 million t / a of ore and 250,000 t / a of rock (among them, 150,000 t / a of quasi-excavated rock and 100,000 t / a of developed rock.).

[0058] According to the distribution of ore bodies, 13 ore rock slide shafts are built in the mining area. The ore rock in the mining area above -180m reaches the -180m level through the slide shafts. The transportation level at the -180m stage adopts a circular layout. In this way, the ore rocks from 13 ore chute shafts are transported to the main chute shaft to prepare raw materials for the lower crushing and lifting system.

[0059] The ore transportation in the stope is driven by a 20t electric locomotive and the 10m3 bottom side u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com