Method and device for carrying out protected casting for shaped blank continuous casting by using single immersed nozzle

A special-shaped billet continuous casting and immersion technology, which is applied in the field of metallurgical continuous casting steel protection and casting, can solve problems such as unreasonable temperature field, and achieve the effect of promoting the floating of inclusions, improving uniformity and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

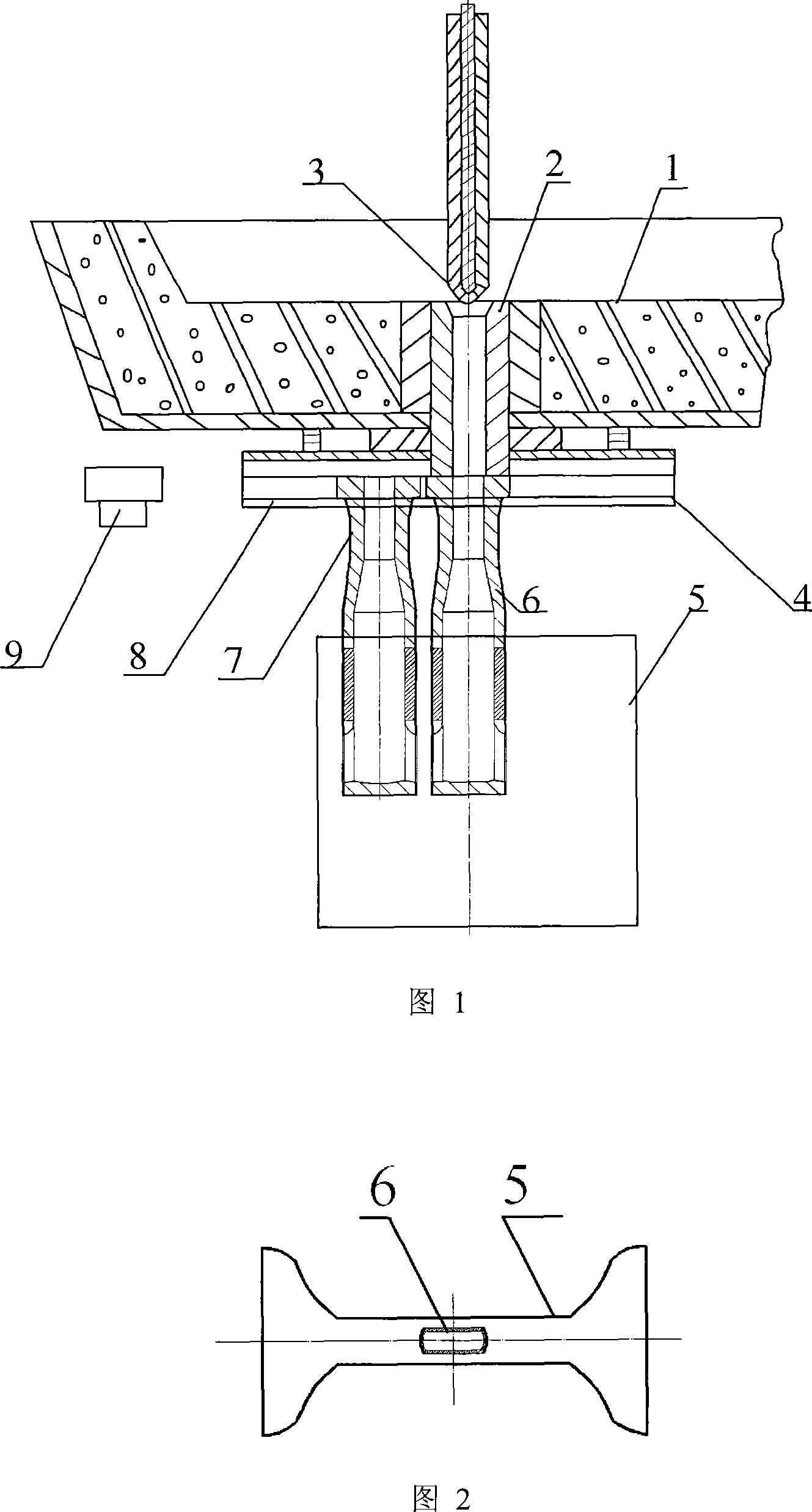

[0028] As shown in Figure 1, the method of the present invention is: insert a submerged nozzle 6 in the middle of the web plate of a shaped billet crystallizer 5 for casting, and the upper nozzle 2 of the tundish 1 through the quick change mechanism 8 above the submerged nozzle connected to form a closed injection channel between the tundish 1 and the crystallizer 5; above the upper nozzle 2, a stopper rod 3 is used to control the injection flow of molten steel so as to realize the liquid level control of the crystallizer.

[0029] The device of the present invention includes a tundish 1 , a submerged nozzle 6 and a profile crystallizer 5 . The tundish 1 is at least provided with an upper nozzle 2 and a corresponding stopper rod 3; there is also at least one quick change mechanism 8 and a submerged nozzle 6; the submerged nozzle 6 is connected to the bottom of the tundish 1 The quick-change mechanism 8 is connected with the upper nozzle 2 in the tundish 1, and the submerged no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com