Working layer for forming continuous casting tundish refractory lining

A continuous casting tundish and refractory lining technology, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of high construction technology requirements and high raw material costs, and achieve strong slag corrosion resistance, simple operation, The effect of improving the operating environment

Inactive Publication Date: 2020-06-30

XINJIANG BAYI IRON & STEEL

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But the disadvantage is that the cost of raw materials is high, the requirements for construction technology are high, and there are high requirements for the operation level of the tundish working layer of the workers.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

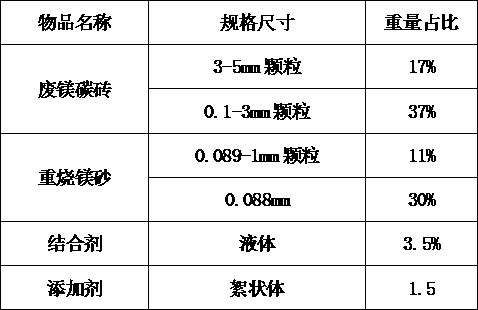

[0031] A working layer constituting the refractory lining of a continuous casting tundish, including a refractory lining of a continuous casting tundish composed of a heat insulating layer, a permanent layer and a working layer, and the weight ratio of the working layer of the tundish is shown in Table 3.

[0032] Table 3: Tundish Working Layer Composition Weight Ratio

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a working layer for forming a continuous casting tundish refractory lining. The continuous casting tundish refractory lining is composed of a heat insulation layer, a permanentlayer and the working layer. The composition proportion of the continuous casting tundish refractory lining is shown in the specification, by weight, 15 to 20% of waste magnesia carbon brick with theparticle size of 3-5 mm, 35 to 40% of waste magnesia carbon brick with the particle size of 0.1-2.9 mm, 8 to 14% of dead burned magnesia with the particle size of 0.089-1 mm, 28 to 32% of dead burnedmagnesia with the particle size of 0.088 mm, 3 to 4% of a binding agent and 1.4 to 1.6% of an additive. The working layer is reasonable in design, the probability of secondary oxidation of molten steel in the tundish can be reduced, hydrogen absorption of the molten steel is reduced, pollution to the molten steel is reduced, the service life of a working layer is prolonged, the quality of steel billets is improved, and the labor productivity in the tundish maintenance process is improved.

Description

technical field [0001] The invention belongs to the improvement of the working layer material constituting the refractory inner lining of the continuous casting tundish, in particular to the working layer constituting the refractory inner lining of the continuous casting tundish. Background technique [0002] The tundish is a transitional device between the crystallizer and the ladle in the steelmaking and continuous casting process. The use of the tundish can make the molten steel injected into the mold better and more smoothly, and can ensure the stability and stability of the molten steel and the role of clean molten steel. Therefore, the tundish In the process of steelmaking, the role is to connect the previous and the next. Tundish refractory lining mainly includes insulation layer, permanent layer and working layer. [0003] The dry material of the tundish is the material of the working layer lining the tundish, which is in direct contact with molten steel and slag, a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/043C04B35/634B22D41/02

CPCC04B35/043C04B35/62204C04B35/63476B22D41/02C04B2235/9676

Inventor 闫芳卜志胜谢英明李明王金城王建海曾广娅金永强陈宝辉米合热古丽·艾提

Owner XINJIANG BAYI IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com