Preparation method of hot rolled steel coil used for oil and gas pipeline

A technology for hot-rolled steel coils and pipelines, which is used in metal rolling, metal rolling, rolling mill control devices, etc. and other problems, to achieve the effect of eliminating corner cracks and center segregation, small performance anisotropy, and reducing the probability of secondary oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

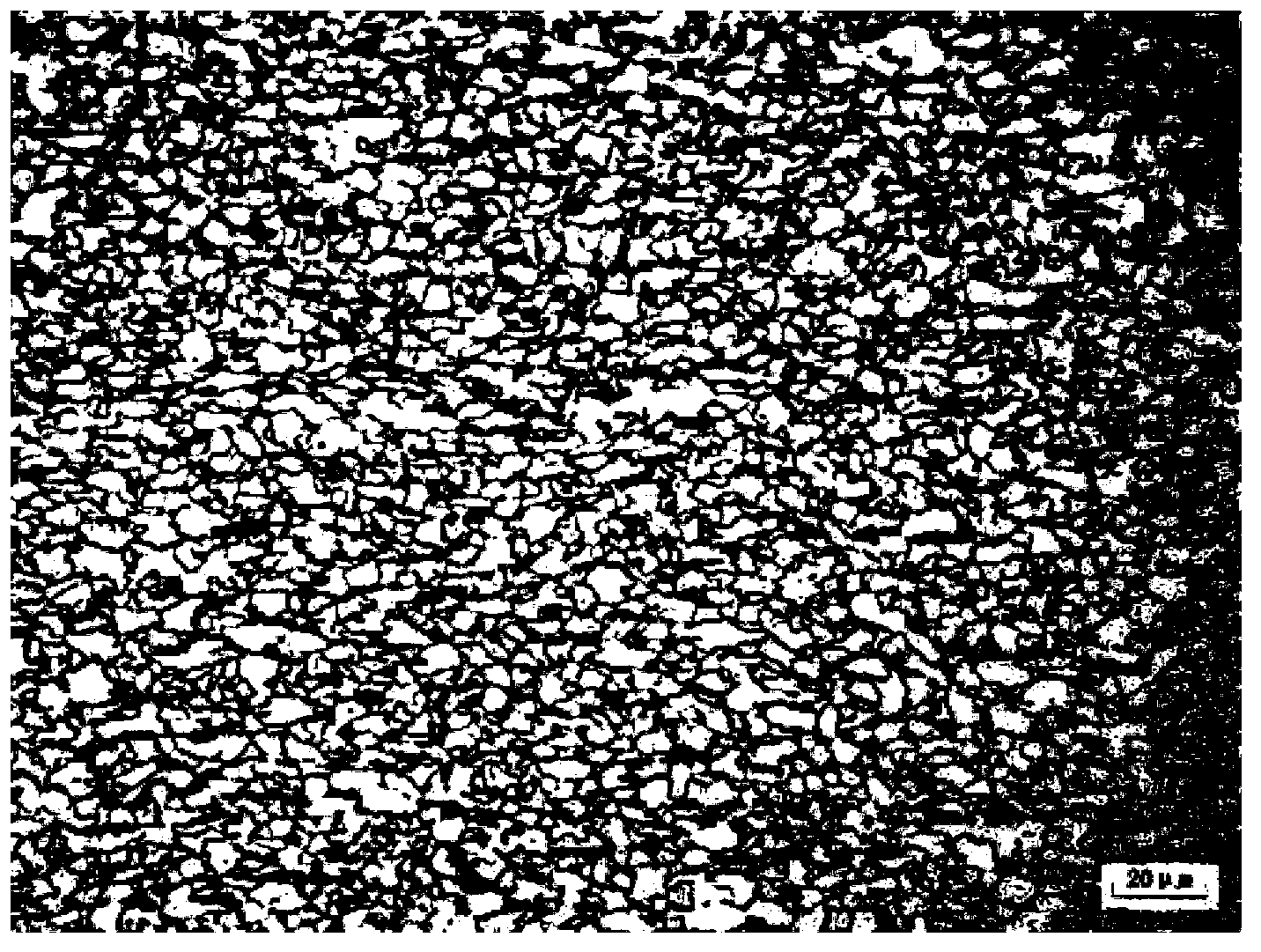

Embodiment 1

[0039] (1) After the composition is designed, desulfurize the molten iron, then carry out converter smelting, switch nitrogen and argon, and then perform deep desulfurization and calcium treatment in the ladle furnace to obtain molten steel;

[0040] (2) Perform continuous casting of the above molten steel to obtain slabs, then heat the obtained slabs, perform rough rolling and finish rolling after dephosphorization by high-pressure water, and finally coil to obtain hot-rolled steel coils;

[0041] The composition of the hot-rolled steel coil is C0.05%, Si0.15%, Mn1.0%, P0.010%, S0.005%, Ti0.025%, Nb0.010% by weight percentage, and the rest is Iron and unavoidable impurities.

[0042] Before the molten steel treatment described in step (1), Ar is weakly blown on the ladle for 5 minutes, and its bright circle is 100 mm; double slag is blocked when tapping.

[0043] The liquidus temperature in the continuous casting described in step (2) TL=1521° C.; the continuous casting is p...

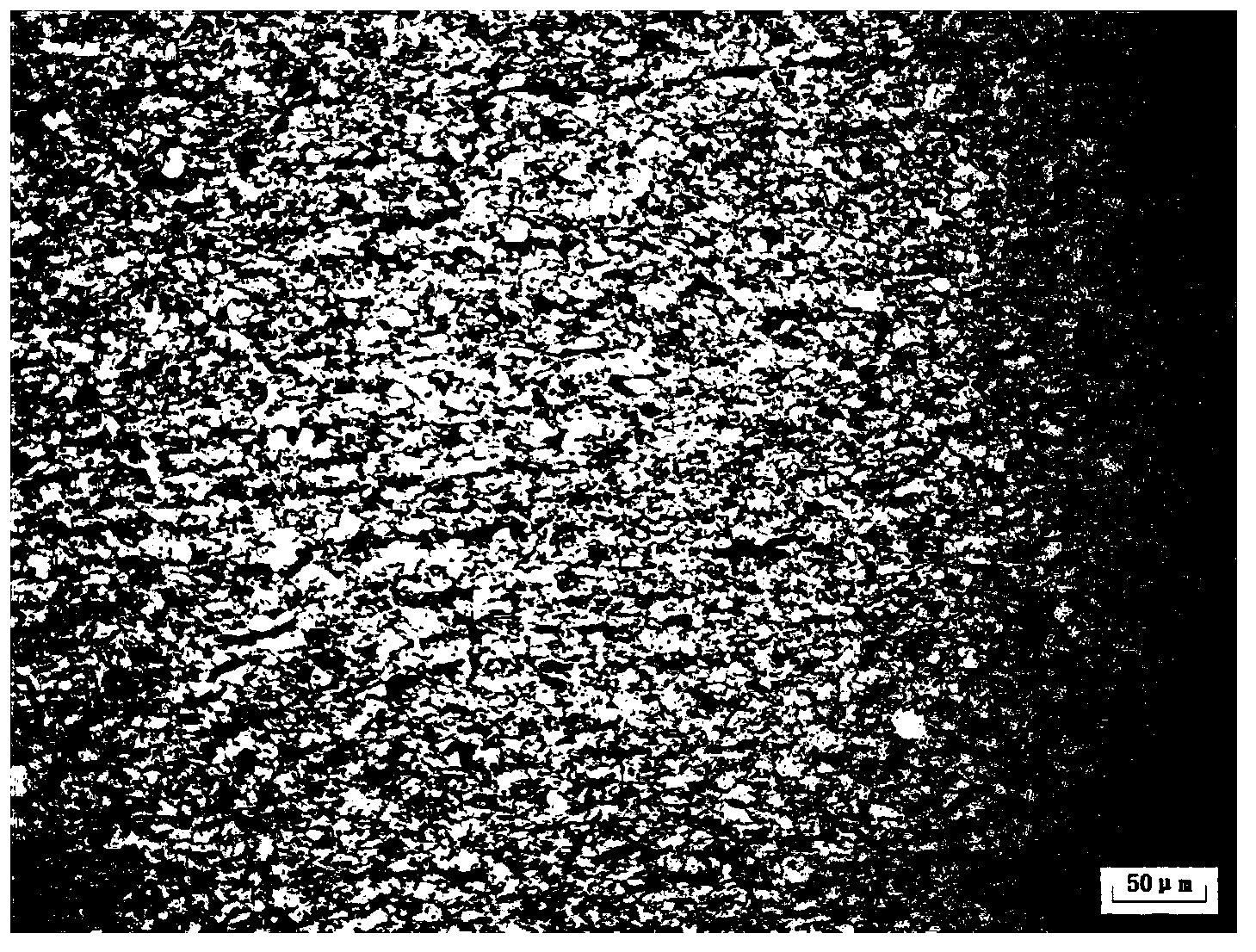

Embodiment 2

[0047] (1) After the composition is designed, desulfurize the molten iron, then carry out converter smelting, switch nitrogen and argon, and then perform deep desulfurization and calcium treatment in the ladle furnace to obtain molten steel;

[0048] (2) Perform continuous casting of the above molten steel to obtain slabs, then heat the obtained slabs, perform rough rolling and finish rolling after dephosphorization by high-pressure water, and finally coil to obtain hot-rolled steel coils;

[0049] The composition of the hot-rolled steel coil is C0.06%, Si0.25%, Mn1.20%, P0.015%, S0.008%, Ti0.030%, Nb0.015% by weight percentage, and the rest is Iron and unavoidable impurities.

[0050] Before the molten steel treatment described in step (1), the ladle is weakly blown with Ar for 6 minutes, and its bright circle is 200 mm; double slag is blocked when tapping.

[0051] The liquidus temperature in the continuous casting described in step (2) TL=1521° C.; the continuous casting is ...

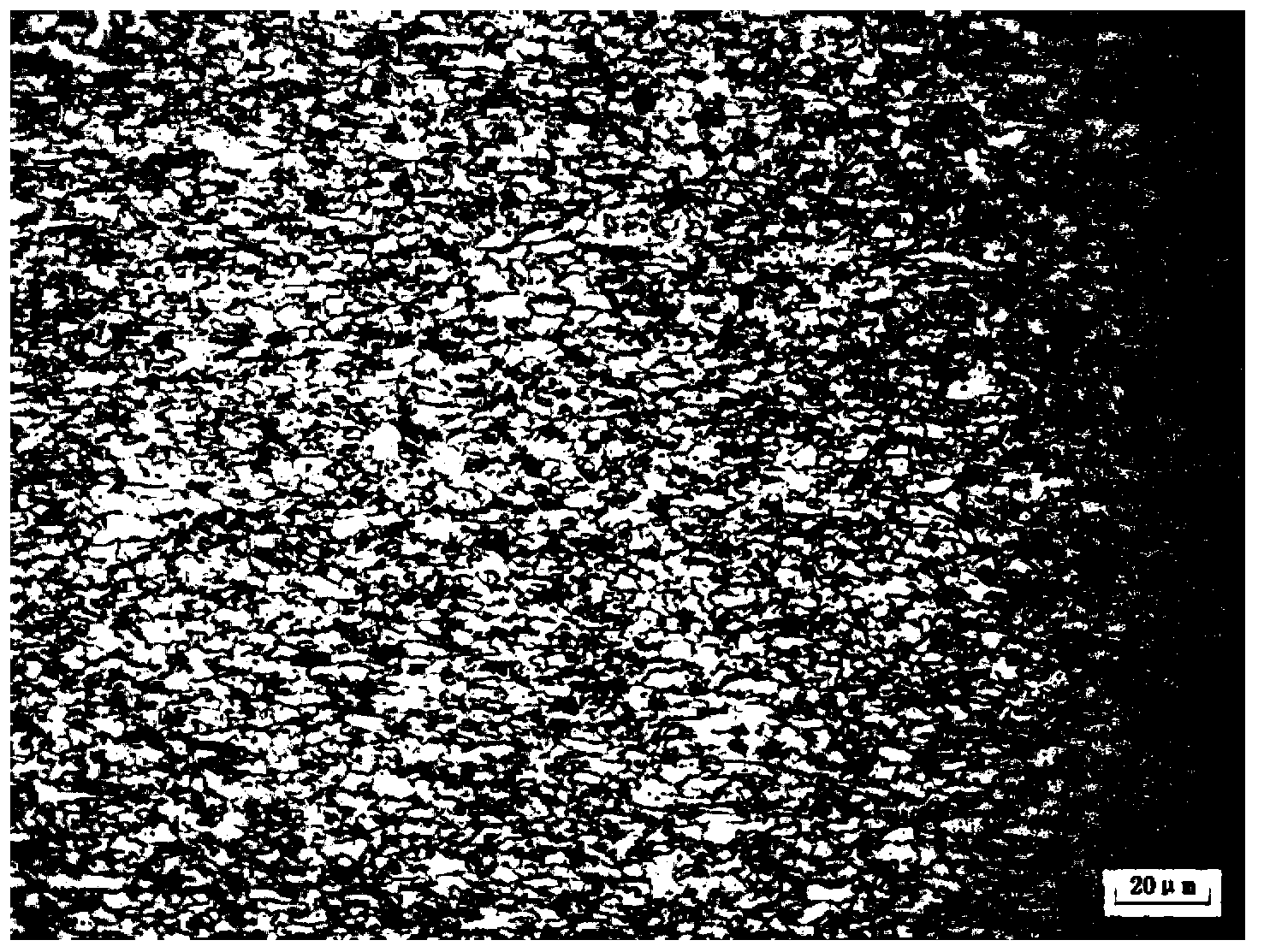

Embodiment 3

[0055] (1) After the composition is designed, desulfurize the molten iron, then carry out converter smelting, switch nitrogen and argon, and then perform deep desulfurization and calcium treatment in the ladle furnace to obtain molten steel;

[0056] (2) Perform continuous casting of the above molten steel to obtain slabs, then heat the obtained slabs, perform rough rolling and finish rolling after dephosphorization by high-pressure water, and finally coil to obtain hot-rolled steel coils;

[0057] The composition of the hot-rolled steel coil is C0.08%, Si0.20%, Mn1.20%, P0.010%, S≤0.009%, Ti0.040%, Nb≤0.018% by weight percentage, and the rest is Iron and unavoidable impurities.

[0058] Before the molten steel treatment in step (1) is completed, Ar is weakly blown on the ladle for 8 minutes, and its bright circle is 150 mm; double slag is blocked when tapping.

[0059] The liquidus temperature in the continuous casting described in step (2) TL=1521° C.; the continuous castin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com