Argon blowing device capable of improving metallurgical ability of tundish and reducing flocculant flow of nozzle and use method thereof

A tundish and nozzle technology, applied in the field of iron and steel metallurgy, can solve problems such as affecting the production rhythm of the production plant, clogging the inner wall of the nozzle, and increasing production costs, and achieve the effects of improving the quality of molten steel, reducing secondary oxidation, and being easy to use and maintain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

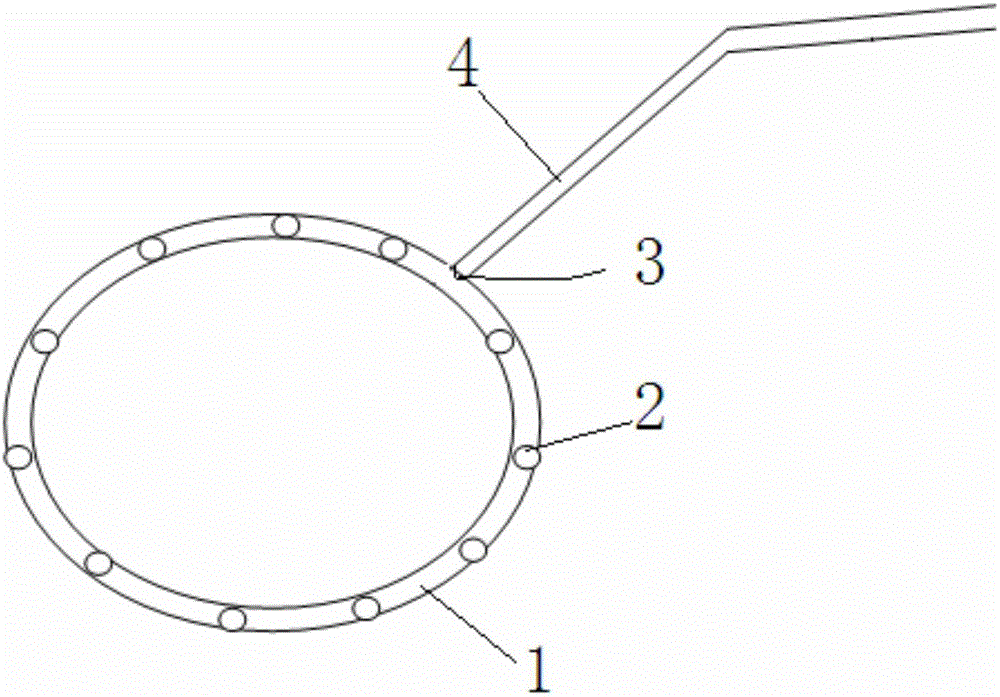

[0022] Such as figure 1 As shown, an argon blowing device for improving the metallurgical capacity of the tundish and reducing nozzle flocculation includes a hollow closed ring 1, and a plurality of air outlet holes 2 for argon to flow out are arranged at even intervals on the closed ring 1. The airtight ring is made of an oxygen-burning tube, and the airtight ring is provided with an air inlet 3, and the air inlet is connected to a section of approximately right-angled ventilation pipeline 4, and the ventilation pipeline is connected to an external argon pipeline connect. A protective casing is provided on the ventilation pipeline at the ladle tapping hole, and the protective casing is closely connected with the ladle tapping hole and is on a central axis. Make sure that the argon ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com