Method and device for filling continuous casting tundish with argon

A continuous casting tundish and tundish technology, used in casting equipment, casting melt containers, metal processing equipment, etc., can solve the problems of large diameter of the pouring hole, secondary oxidation of molten steel, affecting the quality of the casting billet, etc. The effect of blowing amount, reducing secondary oxidation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

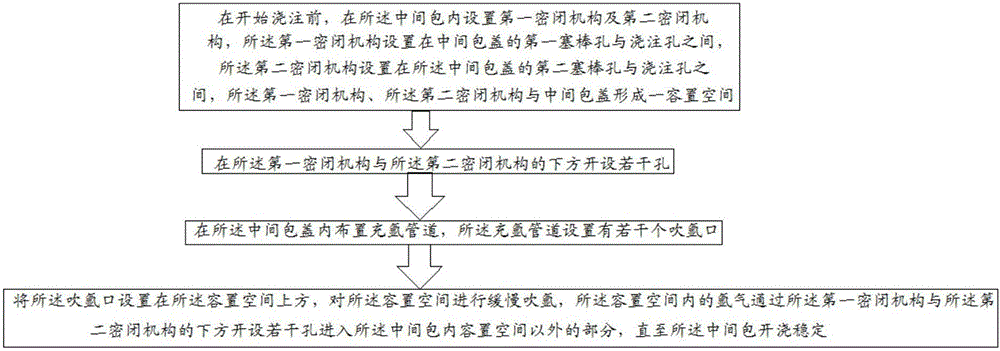

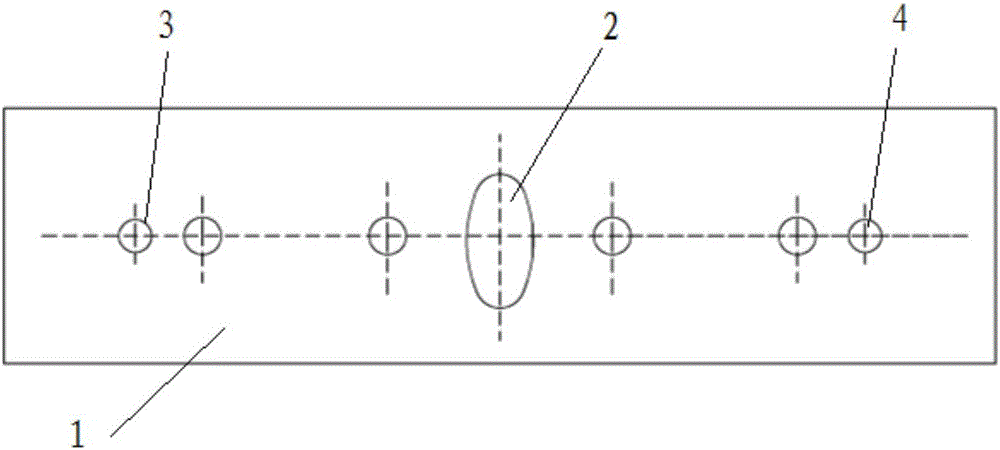

[0020] see figure 1 A method for filling argon in a continuous casting tundish provided in an embodiment of the present invention includes the following steps:

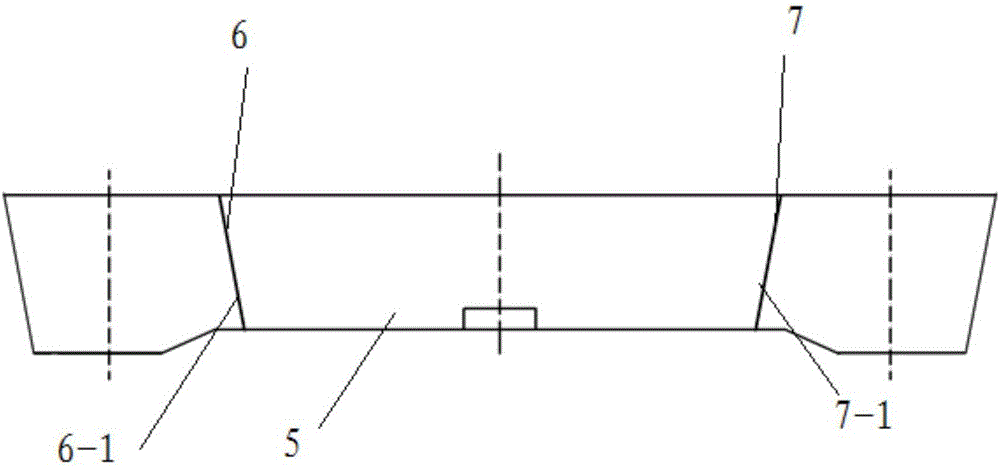

[0021] Step 1, before starting pouring, a first sealing mechanism 6 and a second sealing mechanism 7 are arranged in the tundish 5, and the first sealing mechanism 6 is arranged between the first stopper hole 3 of the tundish cover 1 and the pouring Between the holes 2, the second sealing mechanism 7 is arranged between the second stopper hole 4 of the tundish cover 1 and the pouring hole 2, the first sealing mechanism 6, the second sealing mechanism 7 and the The tundish cover 1 forms an accommodating space.

[0022] Step 2, opening several holes under the first sealing mechanism 6 and the second sealing mechanism 7 .

[0023] Step 3, arrange an argon filling pipeline in the tundish cover 1, and the argon filling pipeline is provided with several argon blowing ports.

[0024] Step 4, setting the argon blowing port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com