Filtering device for magnesium alloy casting and pouring

A filter device, magnesium alloy technology, applied in casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to remove tiny particles, no adsorption capacity on the surface, difficult to remove flux impurities, etc., to reduce the phenomenon of secondary oxidation , improve the filtering effect, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is based on the technical solution of the present invention, and provides detailed implementation methods and specific operating procedures, but the scope of protection of the present invention is not limited to the following embodiments. .

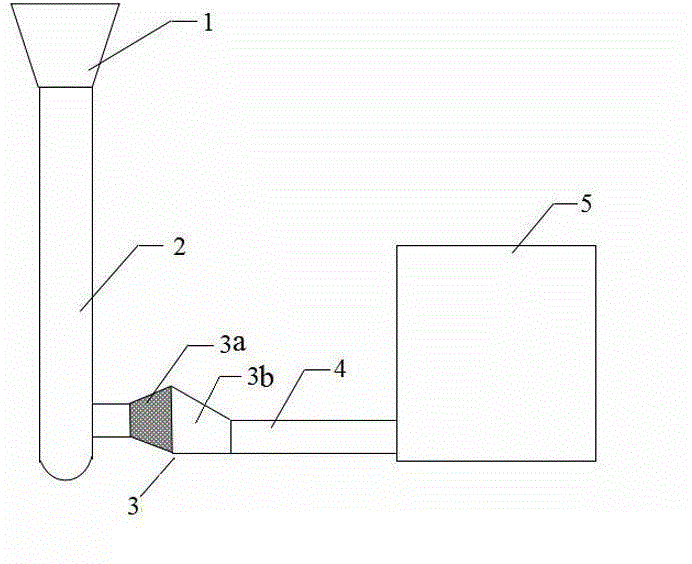

[0012] As shown in the figure, a magnesium alloy casting and pouring filter device is arranged between the sprue cup 1 and the connecting pipe of the casting mold 5, and consists of the sprue 2, the runner 4 and the sprue 4 is composed of a filter tank 3 in the middle, the upper part of the sprue 2 is sealed and connected with the liquid outlet of the sprue cup 1, and the lower part of the sprue 2 is connected with the casting mold 5 through the runner 4. The filter tank It consists of two parts, the filter tank left box 3a and the filter tank right box 3b, which are fastened and connected to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com