Gating system for casting chemical standard blanks

A pouring system and standard sample technology, which is applied to casting molding equipment, casting molds, and casting mold components, can solve the problem of reducing the chemical stability and accuracy of standard sample blanks, prolonging the time from melting to pouring, and affecting chemical standards. The quality of sample blanks and other issues can be reduced to achieve the effects of low probability of secondary oxidation, reduced energy consumption, and avoiding casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings.

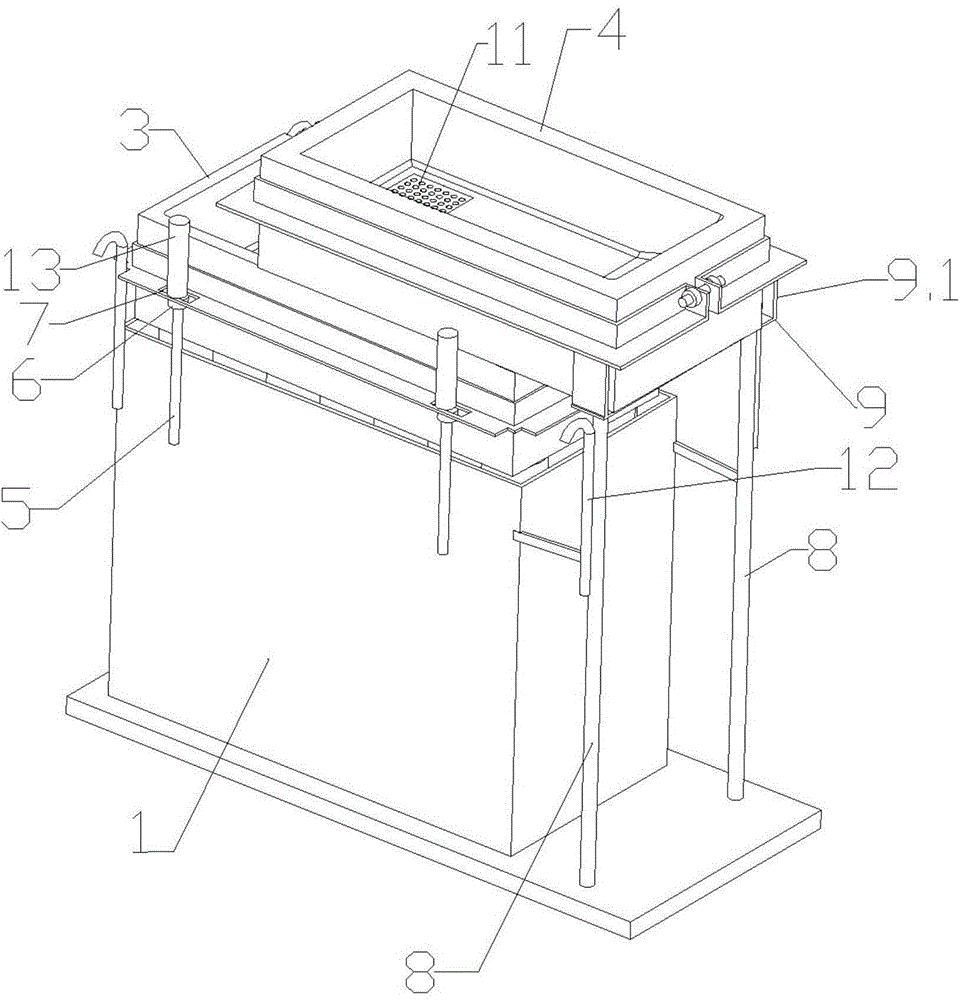

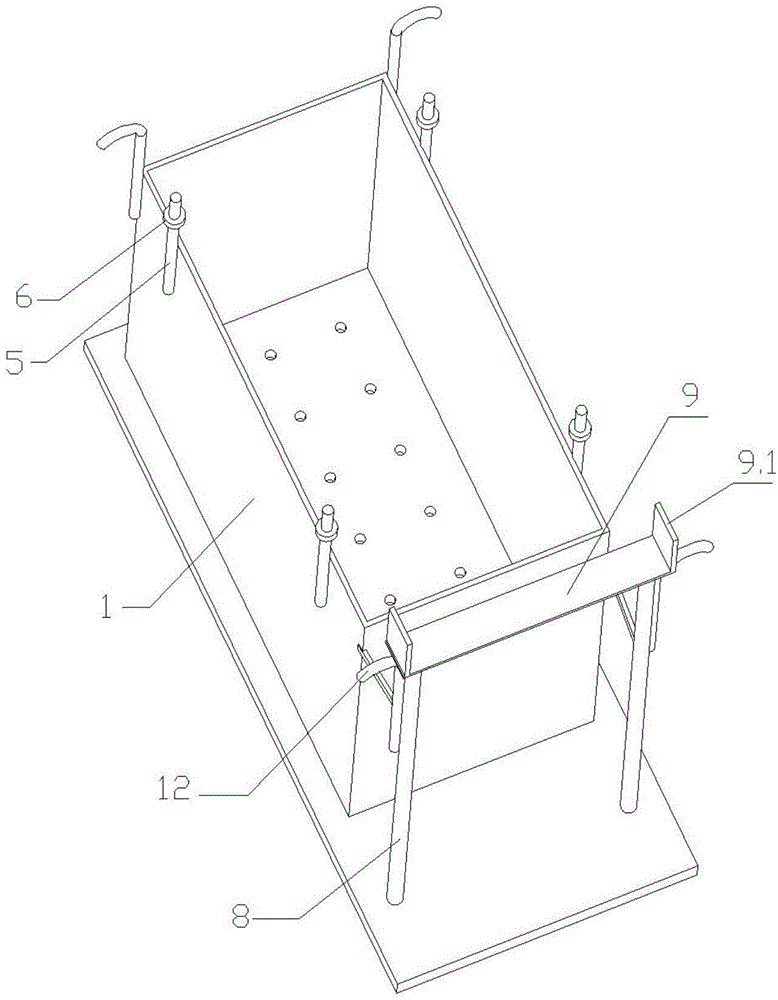

[0022] As shown in the figure, a pouring system for casting chemical standard sample blanks includes a base box 1 with an open top and a plurality of forming molds 2 positioned in the base box 1. The base box 1 includes a box body and a bottom substrate. The top of the box body is open and has an open structure. The bottom of the box body is sealed by the bottom substrate. The bottom substrate is provided with a plurality of positioning holes for the positioning of the forming mold 2 .

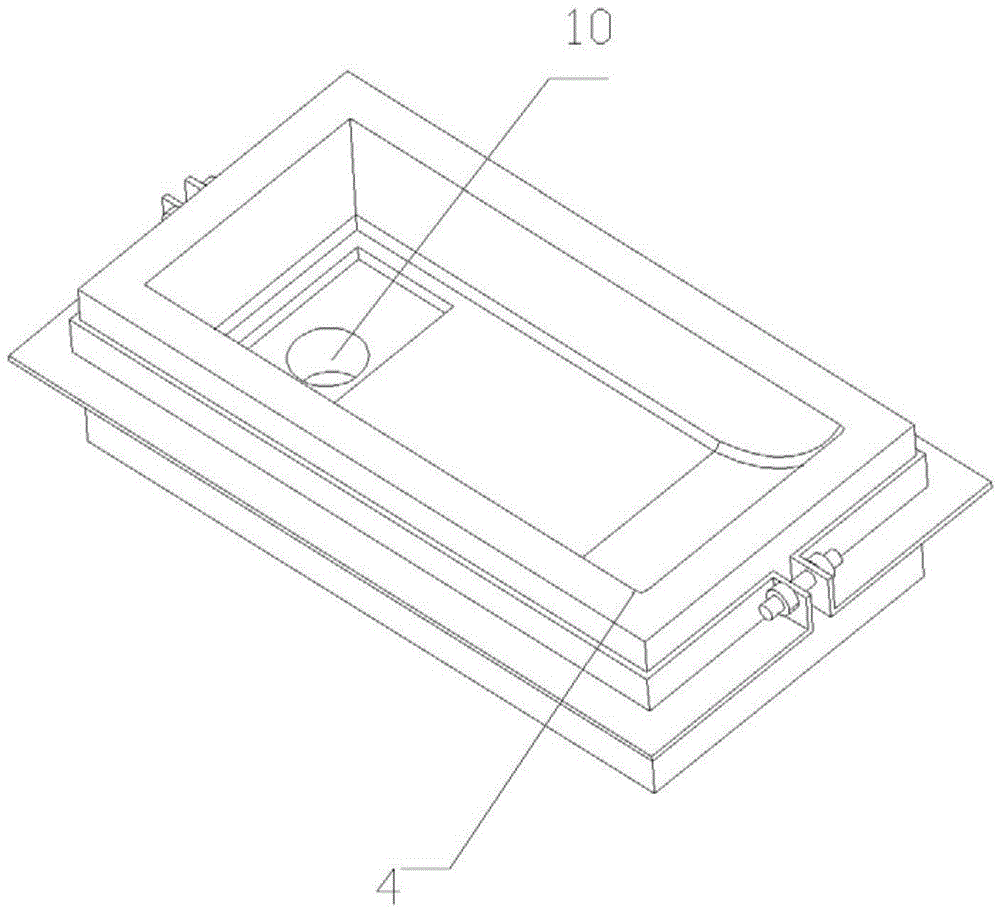

[0023] The pouring system for casting chemical standard sample blanks of the present invention also includes a current collector 3 positioned on the open end of the base box 1 via a positioning structure, and is placed on the current collector 3 and one end is limited left and right and supported on the base box. 1 The damper 4 on the support body. The current collector 3 is positioned on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com