Fluidized reduction furnace for producing high-purity vanadium trioxide and production method

A vanadium trioxide and fluidization technology, applied in the direction of vanadium trioxide, etc., can solve the problems of unsuitability for high-purity vanadium trioxide, unstable product quality, low reaction efficiency, etc., to avoid material agglomeration and improve operation Stability and the effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

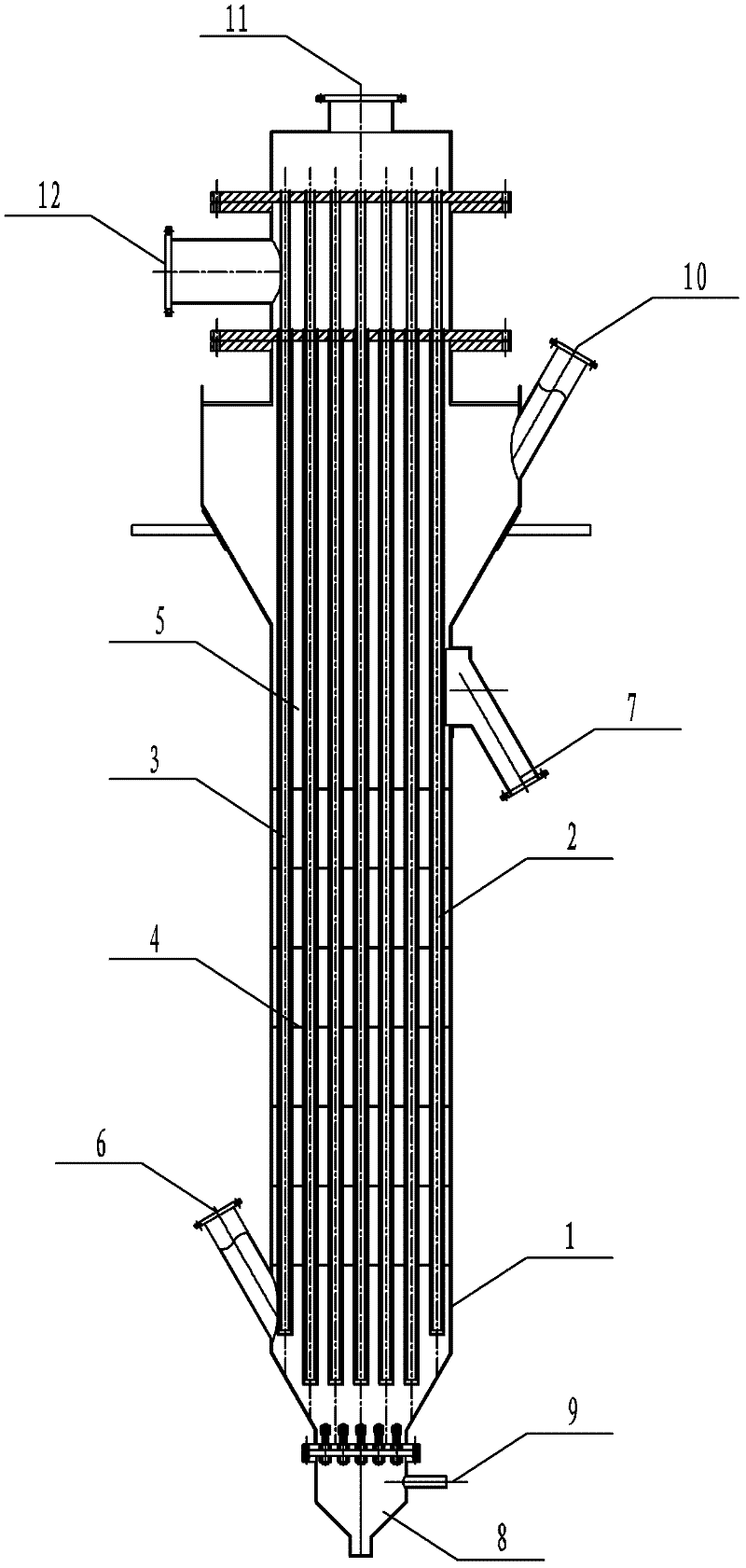

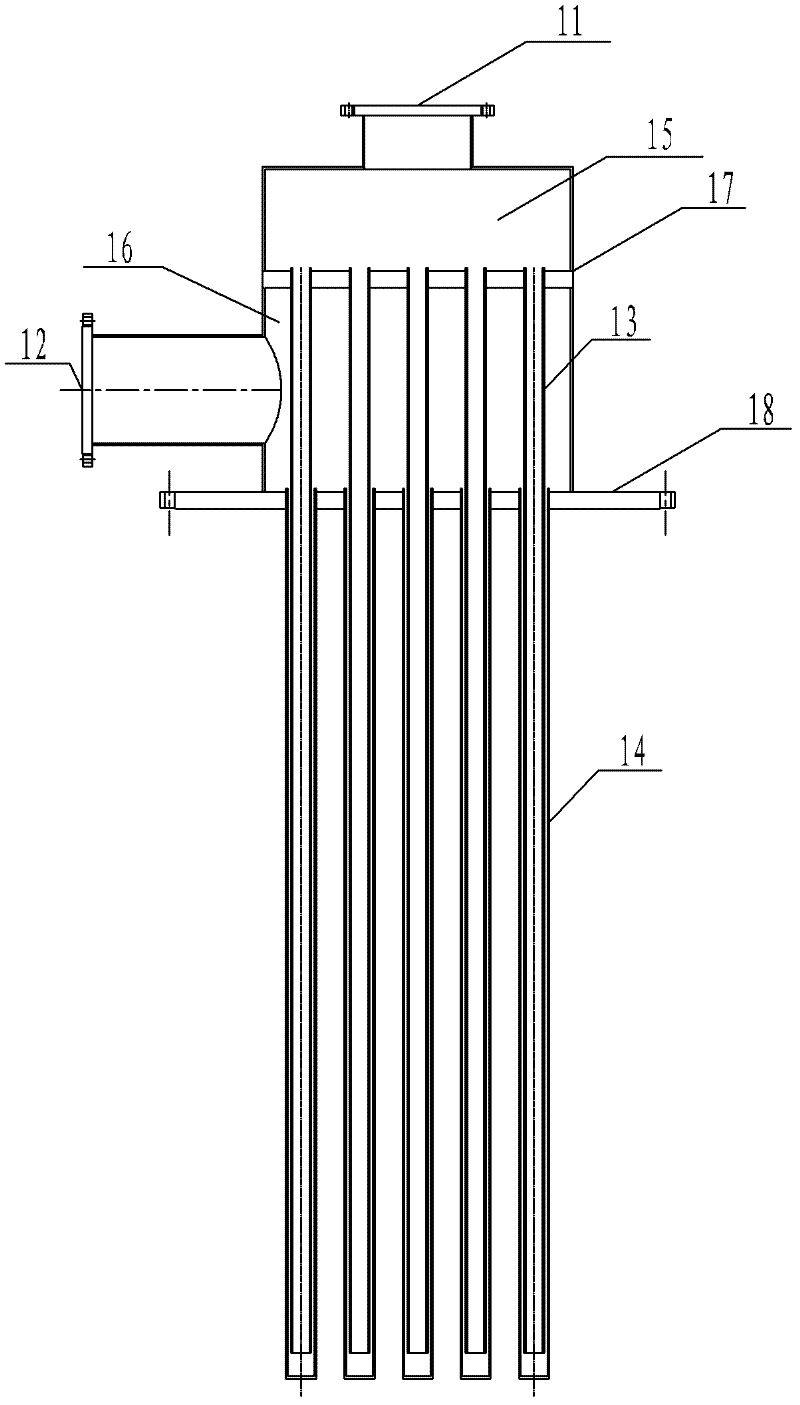

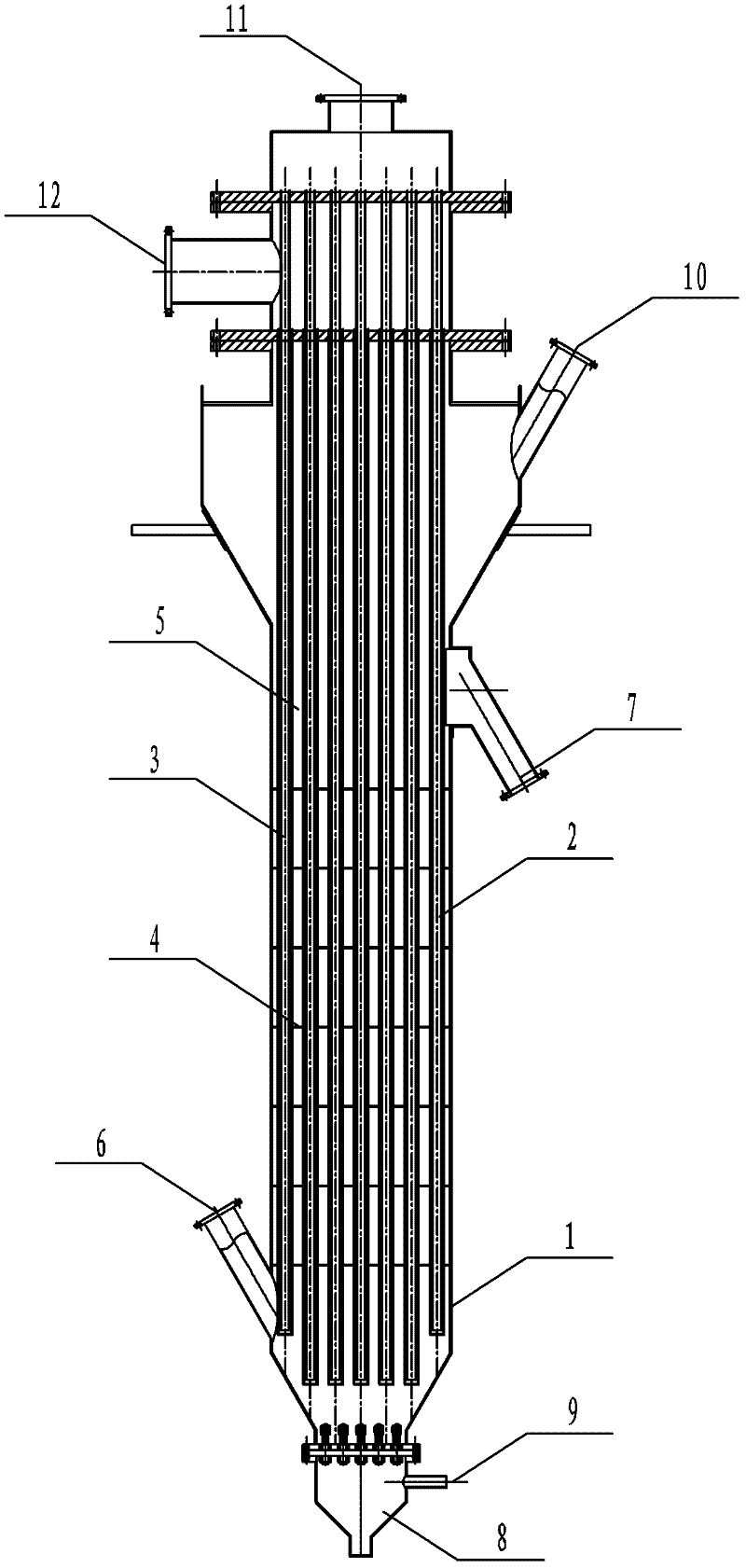

[0038] With a feed rate of 300kg / h, ammonium vanadate powder enters the figure 1 The eight-layer fluidized reduction furnace shown. The flue gas at 1000°C enters the fluidized reduction furnace from the flue gas inlet and heats it. The temperatures of the first to eighth floors are 353°C, 446°C, 535°C, 603°C, 668°C, 728°C, 780°C, 823°C. 150Nm 3 / h of coke oven gas enters from the air funnel at the bottom of the fluidized reduction furnace, and floats the ammonium vanadate powder that enters from the feed inlet, and the ammonium vanadate powder passes through the first to eighth layers in turn, and is gradually heated and reduced , and finally discharged from the outlet after cooling. The reaction tail gas is discharged from the tail gas outlet of the expansion section; the heat supply medium after heat exchange is discharged from the outlet.

Embodiment 2

[0040] With a feed rate of 200kg / h, the vanadium pentoxide powder enters the five-layer fluidized reduction furnace. The flue gas at 950°C enters the fluidized reduction furnace from the flue gas inlet and heats it. The temperatures of the first to fifth floors are 363°C, 485°C, 598°C, 709°C, and 802°C respectively. 140Nm 3 The coke oven gas per hour enters from the air funnel at the bottom of the fluidized reduction furnace, and the vanadium pentoxide powder that enters from the feed inlet floats up, and the vanadium pentoxide powder passes through the first to fifth layers in sequence, and is gradually Heat reduction, and finally discharged from the discharge port. The reaction tail gas is discharged from the tail gas outlet of the expansion section; the heat supply medium after heat exchange is discharged from the outlet.

Embodiment 3

[0042] At a feed rate of 400kg / h, the ammonium vanadate powder enters the ten-layer fluidized reduction furnace. The flue gas at 1000°C enters the fluidized reduction furnace from the flue gas inlet and heats it. The temperatures of the first to tenth floors are 327°C, 426°C, 515°C, 584°C, 648°C, 702°C, 751°C, 793°C, 823°C, 842°C. 170Nm 3 / h of coke oven gas enters from the air funnel at the bottom of the fluidized reduction furnace, and floats the ammonium vanadate powder that enters from the feed inlet, and the ammonium vanadate powder passes through the first to tenth layers in turn, and is gradually heated and reduced , and finally discharged from the outlet. The reaction tail gas is discharged from the tail gas outlet of the expansion section; the heat supply medium after heat exchange is discharged from the outlet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com