Automatic continuous casting billet flame cleaning device and operation method thereof

A technology for flame cleaning and continuous casting slabs, which is applied to gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to clean high-temperature continuous casting slabs, rough corners of continuous casting slabs, and high labor intensity, and achieve The effect of reducing labor intensity, reducing production cost and high operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

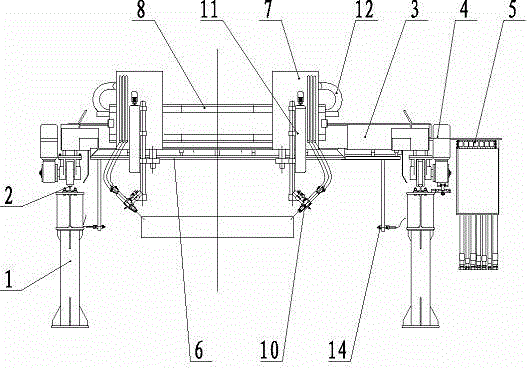

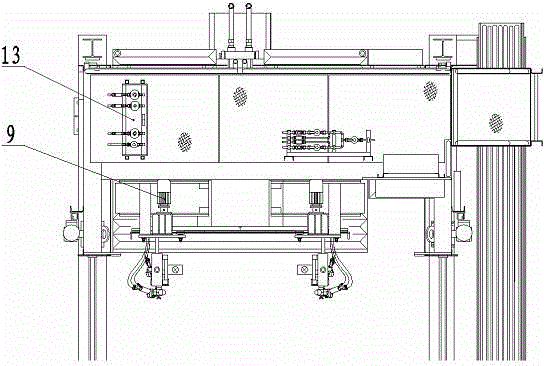

[0015] Such as figure 1 and figure 2 As shown, the device consists of support frame 1, cart track 2, cleaning machine cart 3, cart driving device 4, cart drag chain 5, heat insulation protection plate 6, cleaning trolley 7, cleaning trolley track 8, trolley Drive device 9, cleaning gun 10, automatic height adjustment device 11, trolley drag chain 12, control valve station 13 and slab straightening device 14 are composed. Wherein, the support frame 1 is installed on the base surface, the cart track 2 is installed on the support frame 1, the cleaning machine cart 3 is placed on the cart track 2, and the heat insulation protection plate 6 is installed on the bottom of the cleaning machine cart 3. Cart driving device 4 is fixed on the cleaning machine cart 3, provides power for cleaning machine cart 3 walking. The cable on the cleaning machine cart 3 and the energy medium pipeline are all connected to the ground power supply device and the energy medium point by the cart drag c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com