Efficient and energy-saving magnetizing roasting rotary kiln

A magnetized roasting, high-efficiency and energy-saving technology, which is applied in the field of rotary kiln, can solve the problems of high energy consumption, etc., and achieve the effects of stable operation of equipment, prevention of sticking, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better describe the present invention, a high-efficiency and energy-saving magnetization roasting rotary kiln of the present invention will be further described in detail below in conjunction with the accompanying drawings.

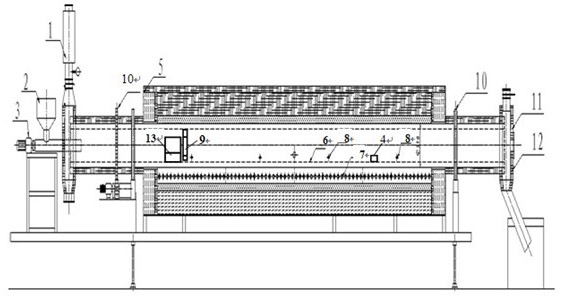

[0027] Depend on figure 1 It can be seen from the schematic cross-sectional structure diagram of a high-efficiency and energy-saving magnetization roasting rotary kiln of the present invention that a high-efficiency and energy-saving magnetization roasting rotary kiln of the present invention is composed of a drive motor, a feeding device, a drum 6 and its transmission support mechanism 10, It is composed of electric heating furnace and electric heating element 7, waste gas exhaust device 1 and discharge device 12 and other parts. A temperature measurement and control device 8 is installed inside the drum 6, the waste gas exhaust device 1 is located at the upper part of the feed end on the side of the kiln tail, the feeding device is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com