Vanadium electrolytic solution and preparation method thereof

A technology of electrolyte and vanadium solution, which is applied in the field of energy chemistry, can solve the problems of low vanadium utilization rate, large loss, difficulty in removing aluminum and silicon elements to less than 0.02%, and achieve the effect of reducing vanadium loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

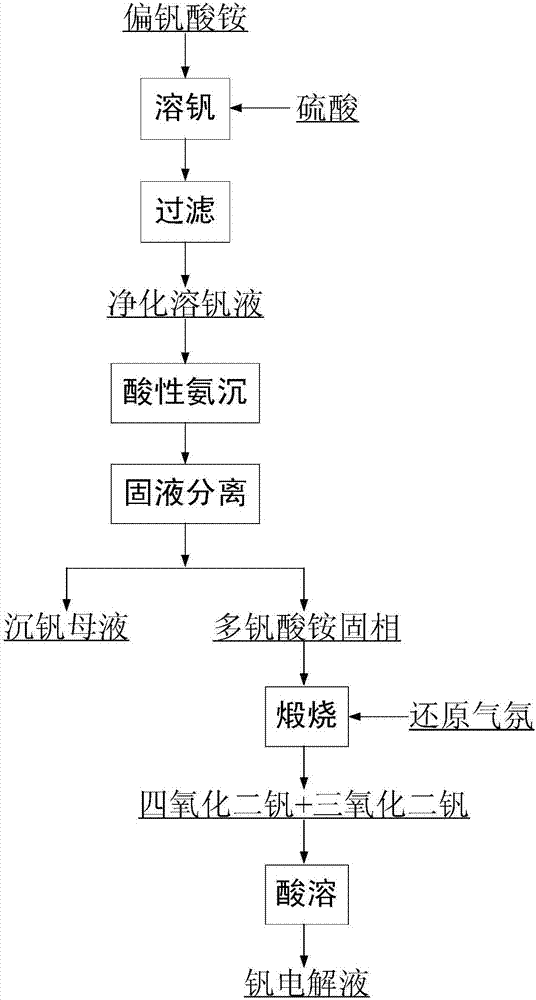

Method used

Image

Examples

Embodiment 1

[0042] 1) Weigh 99.5g of ammonium metavanadate with a purity of 99.5% and a water content of about 10%, put it into 3L of water, slowly add sulfuric acid to pH 5, react at a constant temperature at 50°C for 50 minutes, and filter to obtain a vanadium concentration of 13g / L The purified vanadium solution; in the purified vanadium solution, sulfuric acid was added dropwise to adjust the pH to 3, and heated and stirred until boiling. After 180 minutes of reaction, the solid-liquid separation was completed to obtain the vanadium precipitation mother liquor and the ammonium polyvanadate solid phase. The solid material was washed with water Times

[0043] 2) The ammonium polyvanadate is calcined at 850°C for 3 hours under a reducing gas atmosphere to obtain a mixture containing vanadium tetroxide and vanadium trioxide, wherein the molar ratio of vanadium tetraoxide to vanadium trioxide is 1.01:1;

[0044] 3) Take the mixture obtained in step 2) and dissolve it with an aqueous sulfuric ac...

Embodiment 2

[0052] 1) Weigh 191g of ammonium metavanadate with a purity of 99.5% and a water content of about 10%, put it into 3L of water, slowly add sulfuric acid to a pH of 3, and react at a constant temperature at 99°C for 10 minutes to obtain a purification with a vanadium concentration of 25g / L Vanadium solution: Add sulfuric acid dropwise to the purified vanadium solution to adjust the pH to 1.5, heat and stir until boiling, and complete the solid-liquid separation after 40 minutes of reaction to obtain the vanadium precipitation mother liquor and the solid phase of ammonium polyvanadate;

[0053] 2) The ammonium polyvanadate is calcined at 980°C for 1 hour under a reducing gas atmosphere to obtain a mixture containing vanadium tetroxide and vanadium trioxide, wherein the molar ratio of vanadium tetraoxide to vanadium trioxide is 1.02:1;

[0054] 3) Take the mixture obtained in step 2) and dissolve it with an aqueous sulfuric acid solution to obtain a vanadium electrolyte with a vanadium...

Embodiment 3

[0056] 1) Weigh 160g of ammonium metavanadate with a purity of 99.5% and a water content of about 10%, put it into 3L of water, slowly add sulfuric acid to a pH of 4.8, and react at a constant temperature of 75°C for 30 minutes to obtain a purification with a vanadium concentration of 21g / L Vanadium solution: Add sulfuric acid dropwise to the purified vanadium solution to adjust the pH to 2.5, and heat and stir until boiling. After 130 minutes of reaction, the solid-liquid separation is completed to obtain the vanadium precipitation mother liquor and ammonium polyvanadate solid phase;

[0057] 2) The ammonium polyvanadate is calcined at 930°C for 2 hours under a reducing gas atmosphere to obtain a mixture containing vanadium tetroxide and vanadium trioxide, wherein the molar ratio of vanadium tetraoxide to vanadium trioxide is 0.95:1;

[0058] 3) Take the mixture obtained in step 2) and dissolve it with an aqueous sulfuric acid solution to obtain a vanadium electrolyte with a vanadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com