Method for producing vanadium trioxide by adopting fluidized bed reactor

A technology of fluidized bed reactor and vanadium trioxide, which is applied in the field of metallurgy and chemical industry, can solve the problems of high heating cost, low heating efficiency, and only suitable for laboratories and small-scale production, so as to improve utilization efficiency, The effect of high heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

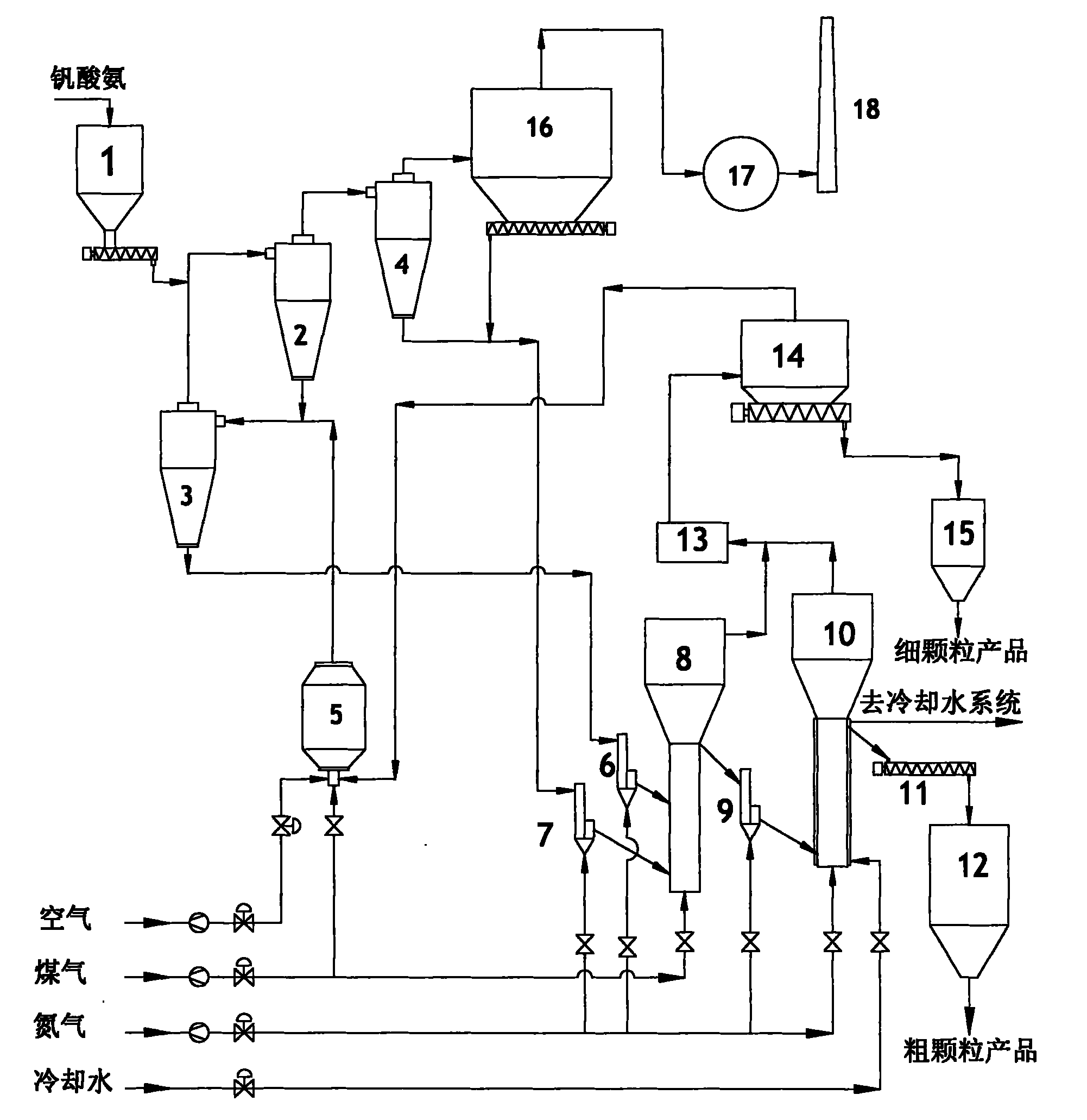

[0029]The ammonium polyvanadate powder enters the primary cyclone preheater 2 and the secondary cyclone preheater 3 from the raw material silo at a rate of 800kg / h, is preheated to about 400°C, and enters the Φ1500×6000mm via feeder 6 Fluidized bed reactor, 200Nm 3 / h The coke oven gas enters from the bottom of the fluidized bed reactor and undergoes a reduction reaction with the material in the bed at 700°C for 20 minutes. Screw conveying into the coarse particle product silo, nitrogen fluidization is used in the fluidized bed cooler, the flow rate is 400Nm 3 / h. The tail gas at the outlet of the fluidized bed reactor is cooled by the tail gas cooler and the fine particle products are collected by the bag filter, and then enters the combustion chamber for combustion. Another coke oven gas 30Nm 3 / h from the gas pipeline directly into the combustion chamber, the air flow is 1300Nm 3 / h, combustion produces high-temperature flue gas at about 1100°C, after heat exchange betwe...

Embodiment 2

[0032] The ammonium polyvanadate powder enters the primary cyclone preheater 2 and the secondary cyclone preheater 3 from the raw material silo at a rate of 800kg / h, is preheated to about 550°C, and enters the Φ1500×6000mm via feeder 6 Fluidized bed reactor, 200Nm 3 / h The coke oven gas enters from the bottom of the fluidized bed reactor and undergoes a reduction reaction with the material in the bed at 850°C for 5 minutes. Screw conveying into the coarse particle product silo, nitrogen fluidization is used in the fluidized bed cooler, the flow rate is 400Nm 3 / h. The tail gas at the outlet of the fluidized bed reactor is cooled by the tail gas cooler, and the fine particle products are collected by the bag filter, and then enters the combustion chamber for combustion. The other coke oven gas 50Nm 3 / h from the gas pipeline directly into the combustion chamber, the air flow is 1500Nm 3 / h, combustion produces high-temperature flue gas at about 1100°C, after heat exchange be...

Embodiment 3

[0035] The vanadium pentoxide powder enters the primary cyclone preheater 2 and the secondary cyclone preheater 3 from the raw material silo at a rate of 600kg / h, is preheated to about 500°C, and enters the Φ1500×6000mm via feeder 6 Fluidized bed reactor, 130Nm 3 / h The coke oven gas enters from the bottom of the fluidized bed reactor and undergoes a reduction reaction with the material in the bed at 800°C for 10 minutes. Screw conveying into the coarse particle product silo, nitrogen fluidization is used in the fluidized bed cooler, the flow rate is 400Nm 3 / h. The tail gas at the outlet of the fluidized bed reactor is cooled by the tail gas cooler and the fine particle products are collected by the bag filter, and then enters the combustion chamber for combustion, and the air flow rate is 300Nm 3 / h, combustion produces high-temperature flue gas at about 1200°C, after heat exchange between the high-temperature flue gas and vanadium pentoxide in the two-stage cyclone prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com