Method for producing vanadium trioxide

A technology of vanadium trioxide and vanadium pentoxide, which is applied in the direction of vanadium oxide, etc., can solve the problems of low production efficiency, low filling rate, and low product grade, etc., and achieve the improvement of equipment utilization rate, production efficiency, and reduction time. The effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: produce vanadium trioxide with the inventive method

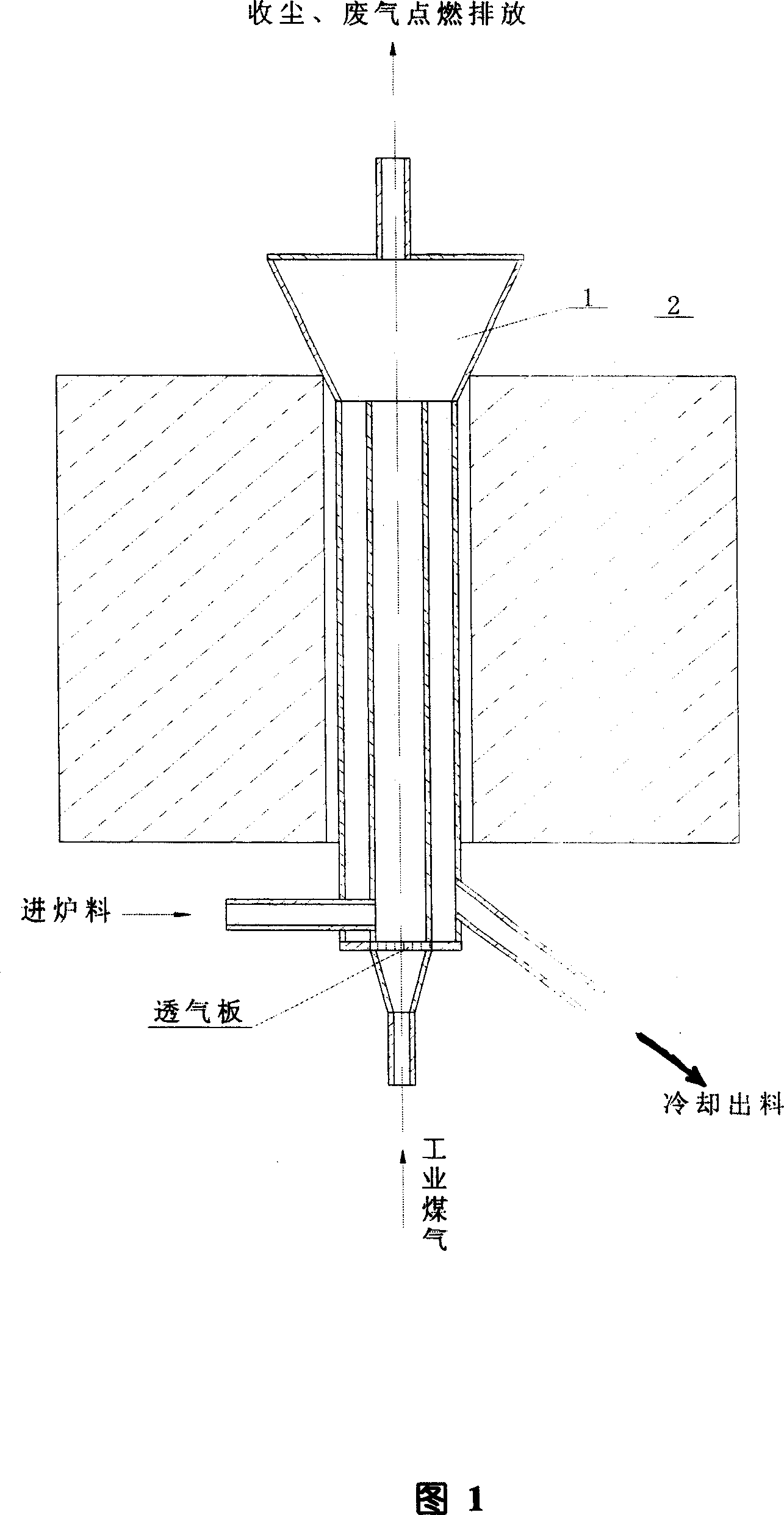

[0030] Use the vertical fluidized furnace of the bottom feeding and bottom discharging mode as shown in Figure 1. The diameter of the fluidized furnace tube 1 is 200 mm and the length is 1500 mm. The structure of the furnace tube is two parts, the inner layer and the outer layer. The furnace tube diameter is 100mm. Add 4kg of powder ammonium vanadate charge (filling rate is about 45%) with a particle size range of 0.1mm to 5.0mm into the inner layer from the feed pipe at the lower part of the fluidized furnace tube, and blast furnace gas from the fluidized furnace The lower end of the layer furnace tube is connected, and the gas flow rate is 2.0Nm 3 / h (standard cubic meter per hour), the external heating furnace 2 simultaneously heats the furnace tube of the fluidized furnace to a temperature of 650°C in the furnace tube; The inner layer of the inner layer moves towards the outer layer cooling discha...

Embodiment 2

[0032] Embodiment 2: produce vanadium trioxide with the inventive method

[0033] Use the vertical fluidized furnace of the bottom feeding and bottom discharging mode as shown in Figure 1. The diameter of the fluidized furnace tube 1 is 200 mm and the length is 1500 mm. The structure of the furnace tube is two parts, the inner layer and the outer layer. The furnace tube diameter is 100mm. Add 2 kg of powder ammonium vanadate charge (filling rate is about 20%) with a particle size range of 0.05mm to 10.0mm into the inner layer from the feed pipe at the lower part of the fluidized furnace tube, and blast furnace gas from the fluidized furnace The lower end of the layer furnace tube is connected, and the gas flow rate is 1.3Nm 3 / h (standard cubic meter per hour), the external heating furnace 2 simultaneously heats the furnace tube of the fluidized furnace to a temperature of 650°C in the furnace tube; The inner layer of the inner layer moves toward the outer layer cooling disc...

Embodiment 3

[0035] Embodiment 3: produce vanadium trioxide with the inventive method

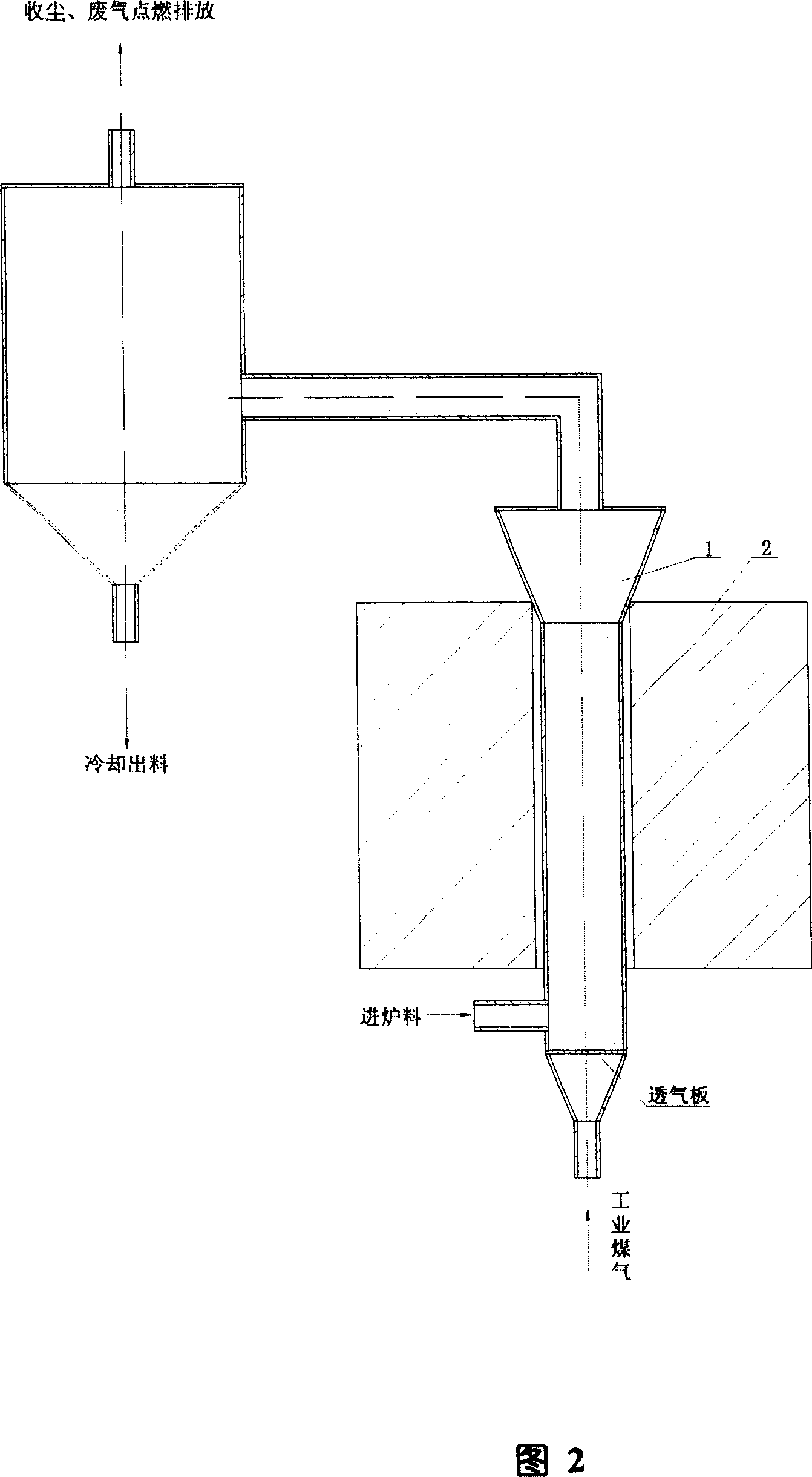

[0036] Use the vertical fluidized furnace of the bottom feeding and top discharging mode as shown in Figure 2, the fluidized furnace tube 1 has a diameter of 100mm and a length of 2500mm, and the powdered ammonium vanadate with a particle size range of 0.05mm to 5.0mm Charge 5kg (filling rate is about 50%) from the lower part of the fluidized furnace tube 1, and pass the coke oven gas from the lower part of the fluidized furnace tube, and the gas flow rate is 2.5Nm 3 / h, while the external heating furnace 2 heats the furnace tube of the fluidized furnace until the temperature inside the furnace tube is 630°C. Under the blowing of the gas, the charge will tumbling and flow in the furnace tube of the fluidized furnace, and move toward the upper cooling outlet. The reduction time is maintained for 5 minutes, and the charge is reduced to powdered vanadium trioxide. By cooling the discharge port, the vanad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com