Process for preparing nano grade vanadium trioxide

A vanadium trioxide, nano-scale technology, applied in the field of functional materials and inorganic chemistry, can solve the problems of high price, high reaction temperature, and long synthesis route, and achieve the effect of low price and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

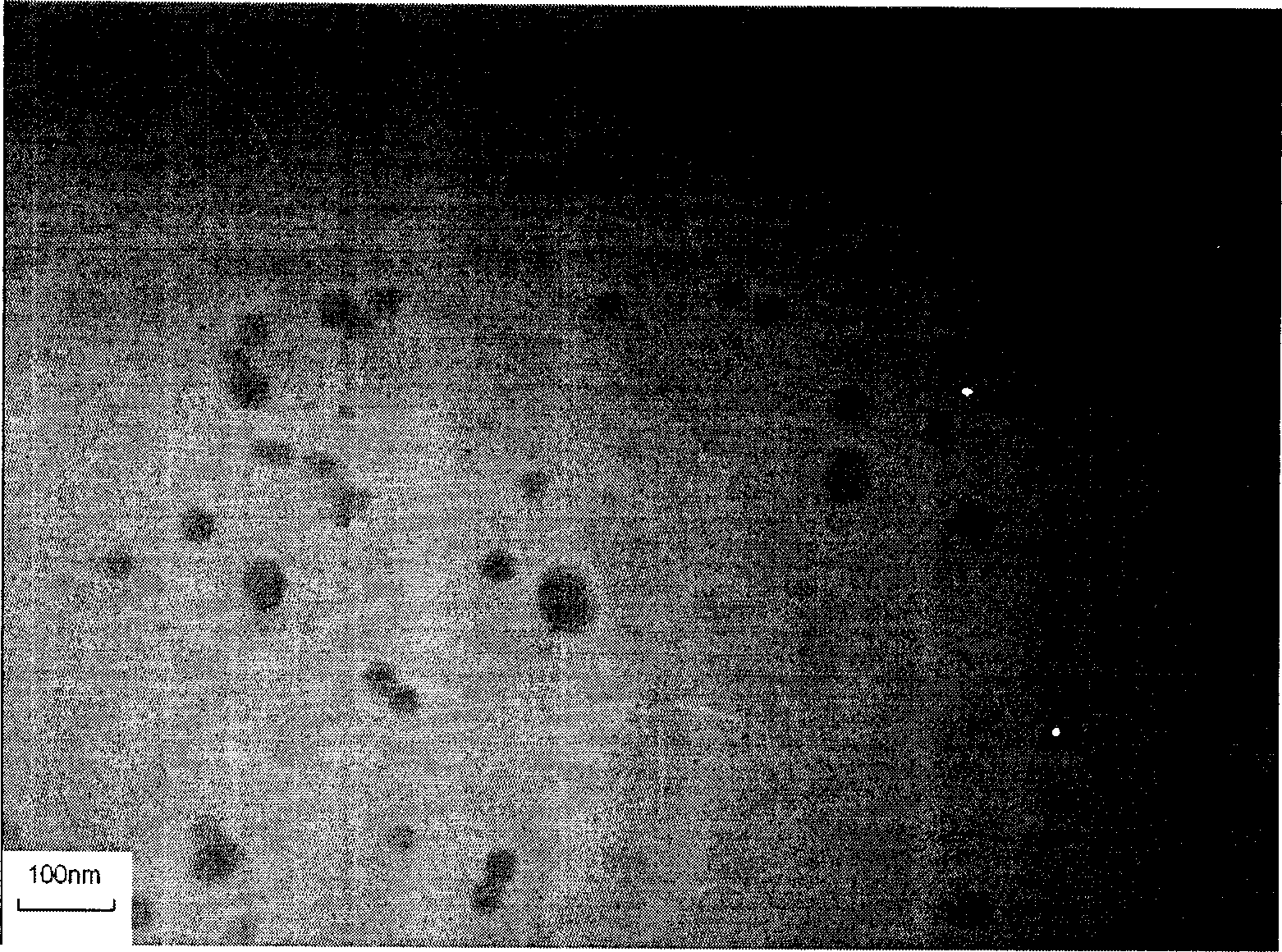

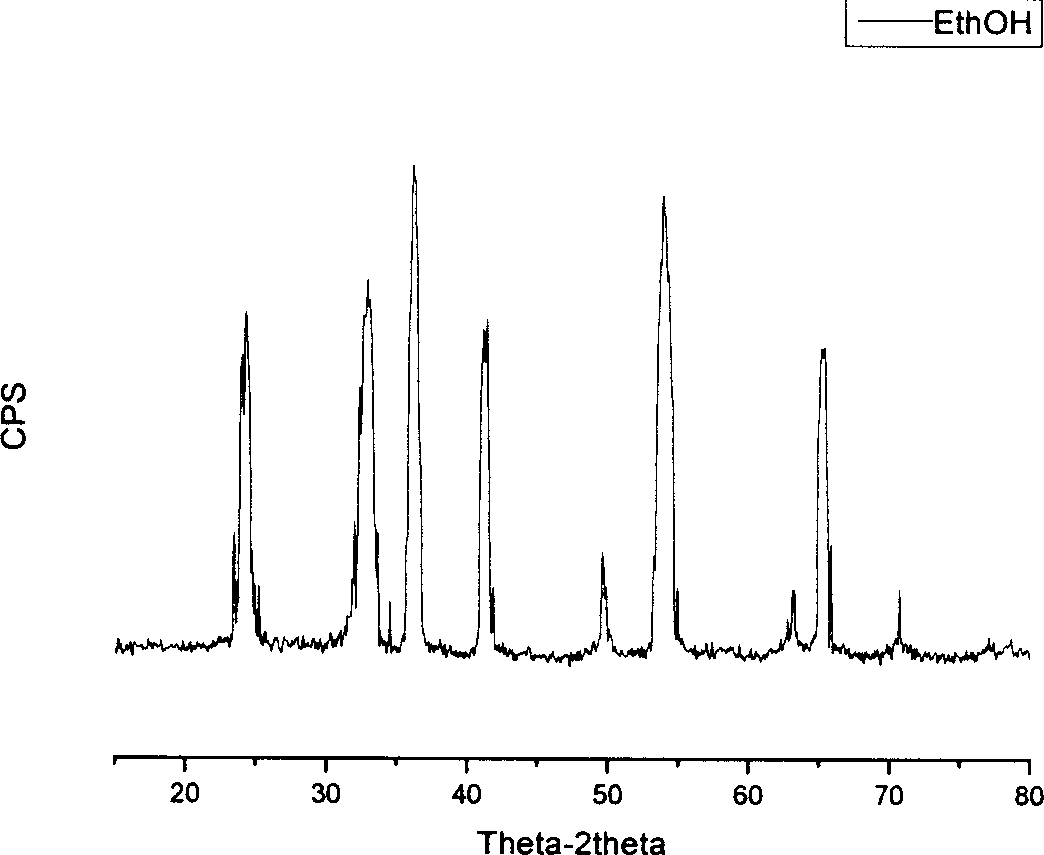

Image

Examples

Embodiment 1

[0023] Will 9.00g V 2 o 5 and 20.2 g H 2 C 2 o 4 2H 2 Add O to 100mL of absolute ethanol, reflux reaction for 2h to obtain VOC 2 o 4 weak. Dilute the solution to 250mL with absolute ethanol, then transfer it to a 0.5L autoclave, seal it and gradually raise the temperature to 250°C, and the system pressure also rises to 9.1MPa. In this case, after 3 hours of incubation, ethanol was released at a constant temperature within 1.7 hours. When the solvent was about to be exhausted, the temperature of the kettle rose sharply, reaching 300°C. Turn off the heat and allow to cool to room temperature. 6.60 g of a black powder were obtained.

Embodiment 2

[0025] 8.00g VOC 2 o 4 Add it to 250mL of methanol, then transfer it to a 0.5L autoclave, and after sealing it, gradually raise the temperature to 200°C, and the system pressure also rises to 7.0MPa. In this case, after 2.4 hours of heat preservation, methanol is released at a constant temperature within 1.2 hours. When the solvent was about to be exhausted, the temperature of the kettle rose sharply, reaching 256°C. Turn off the heat and allow to cool to room temperature. Obtained 3.34g black Nano V 2 o 3 powder.

Embodiment 3

[0027] 8.00g VOC 2 o 4 Dissolve in 250mL of ethanol and isopropanol mixed solvent (volume ratio is 2:1), then transfer to a 0.5L autoclave, seal it and gradually raise the temperature to 245°C, and the system pressure also rises to 7.8MPa. In this case, after 2.0 hours of heat preservation, the solvent was released at a constant temperature within 1.0 hours. When the solvent was about to be exhausted, the temperature of the kettle rose sharply and reached 270°C. Turn off the heat and allow to cool to room temperature. Get 3.30g black Nano V 2 o 3 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com