High vanadium ferroalloy smelting method and ingot mould for smelting high vanadium ferroalloy

A smelting method and technology of high-vanadium ferro-vanadium, which is applied in the field of high-vanadium ferro-vanadium smelting and ingot molds for high-vanadium ferro-vanadium smelting, can solve the problems of high residual vanadium in slag, segregation of ferro-vanadium, production can not go smoothly, etc., to overcome the difficulty of breaking , changing the structure of ferrovanadium and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

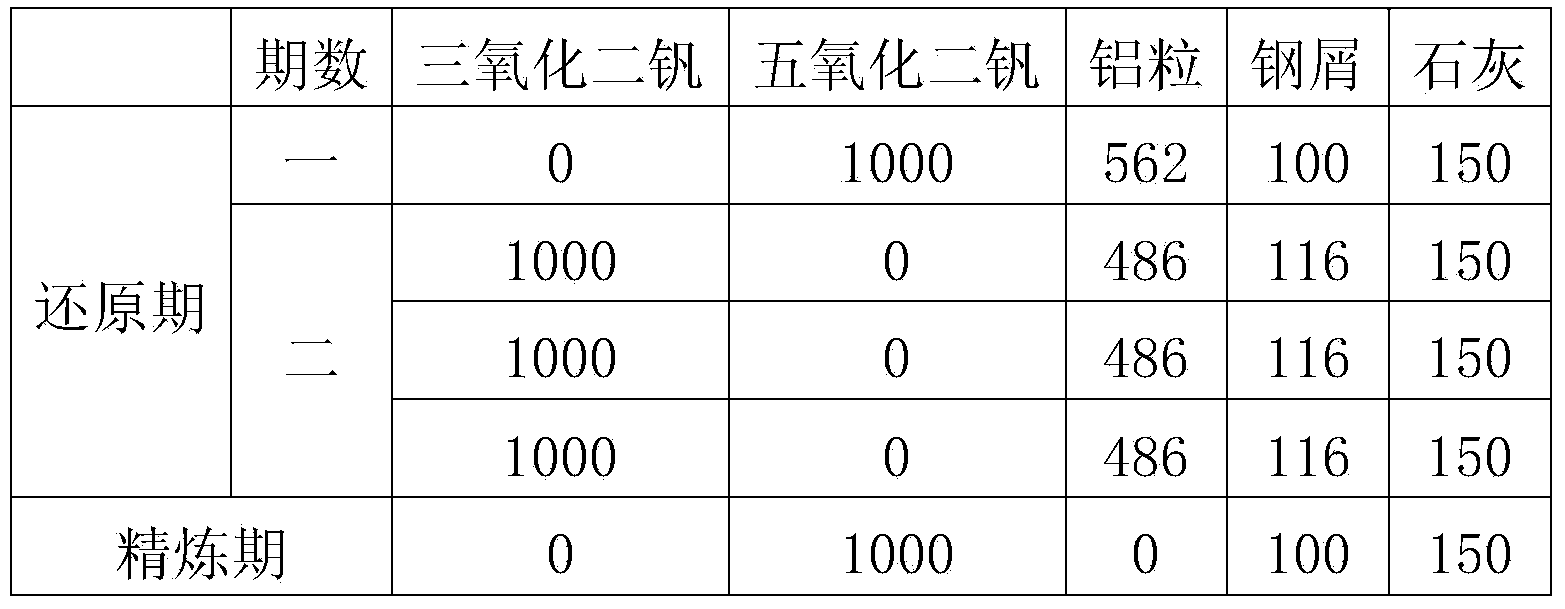

[0029] First carry out batching, each compound used and its proportioning ratio are as shown in Table 1.

[0030] Use 500 kg of vanadium-containing rich slag and 200 kg of lime as the bottom, quickly add the first-stage mixture into the electric arc furnace, turn on the electricity, and then return 1500 kg of hot vanadium-containing rich slag from the previous furnace to the furnace. 190V high-voltage full-load power transmission is used to speed up the chemical material speed. After 20-30 minutes of smelting, through visual inspection and sampling analysis, when the V content in the smelting slag is 0.48%, the first phase of poor slag is produced, and a low voltage of 135V and a low current of 6000A are used for slag production.

[0031] After the first stage of poor slag is discharged, enter the second stage of reduction, switch to a high voltage of 150V and a high current of 15000-18000A, add the second-stage mixture and the feeding speed of 78~ depends on the furnace condi...

example 2

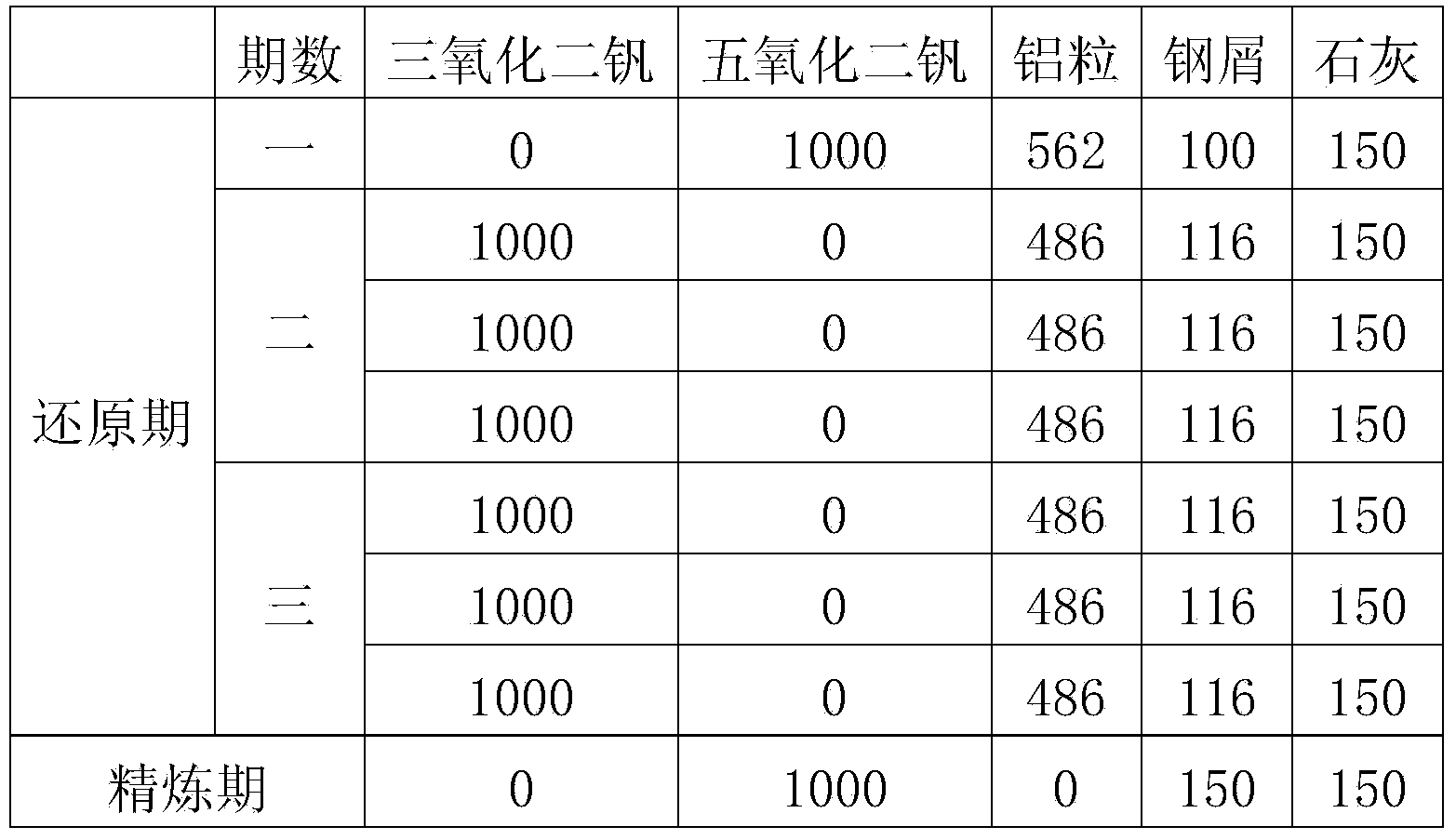

[0038] First carry out batching, each compound used and its proportioning ratio are as shown in Table 2.

[0039] Use 500 kg of vanadium-containing rich slag and 200 kg of lime as the bottom, quickly add the first-stage mixture into the electric arc furnace, turn on the electricity, and then return 2000 kg of hot vanadium-containing rich slag from the previous furnace to the furnace. 190V high-voltage full-load power transmission is used to speed up the chemical material speed. After 20 to 30 minutes of smelting, through visual inspection and sampling analysis, when the V content in the smelting slag is 0.45%, the first phase of poor slag is produced, and a low voltage of 135V and a low current of 6000A are used for slag production.

[0040] After the first phase of poor slag is discharged, enter the second phase of reduction, switch to a high voltage of 150V and a high current of 15000-18000A, add the mixture of the second phase, and the feeding speed depends on the furnace c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com