Seawater desalination method implemented by solar membrane distillation

A solar membrane and membrane distillation technology, which is applied in the field of water desalination, can solve the problems of low energy consumption, low cost and high water production efficiency, lack of potential for scale-up and practical application, configuration optimization and thermal energy utilization. Less problems, to avoid direct heat conduction loss, save the condensate cooling link, the effect of small steam mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

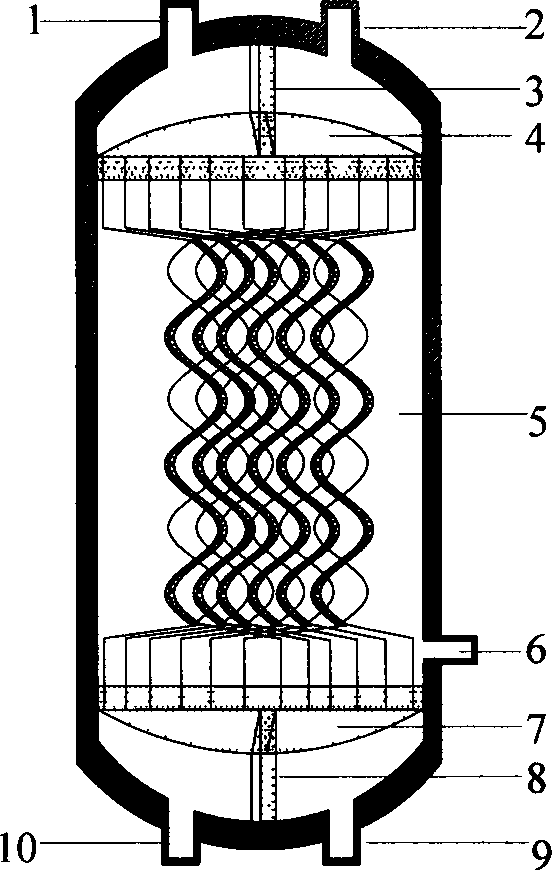

[0049] Embodiment 1: single-group multi-stage mode.

[0050] Inlet of hot liquid and condensate: ordinary sea water, TDS 31600mg / L;

[0051] The inlet temperature of hot liquid and condensate are respectively: 90°C and 25°C;

[0052] Hot liquid, condensate flow rate: 45L / h;

[0053] Solar heat collector heat collection area: 2.25m 2 ;

[0054] The number of hollow fiber membranes in the membrane module is 120, and the number of hollow fiber condenser tubes is 360. The hollow fiber material is polytetrafluoroethylene (PTFE), the inner diameter of the hollow fiber membrane is 0.6mm, the thickness is 0.2mm, the average pore The inner diameter of the fiber condenser tube is 0.5mm, the thickness is 0.15mm, the number ratio of the hollow fiber membrane to the hollow fiber condenser tube is 1:3, the inner diameter of the heat-insulating tubular spacer is 1.0mm, the thickness is 0.5mm, the gap between the hollow fiber membrane and the hollow fiber condenser tube The thickness is 0...

Embodiment 2

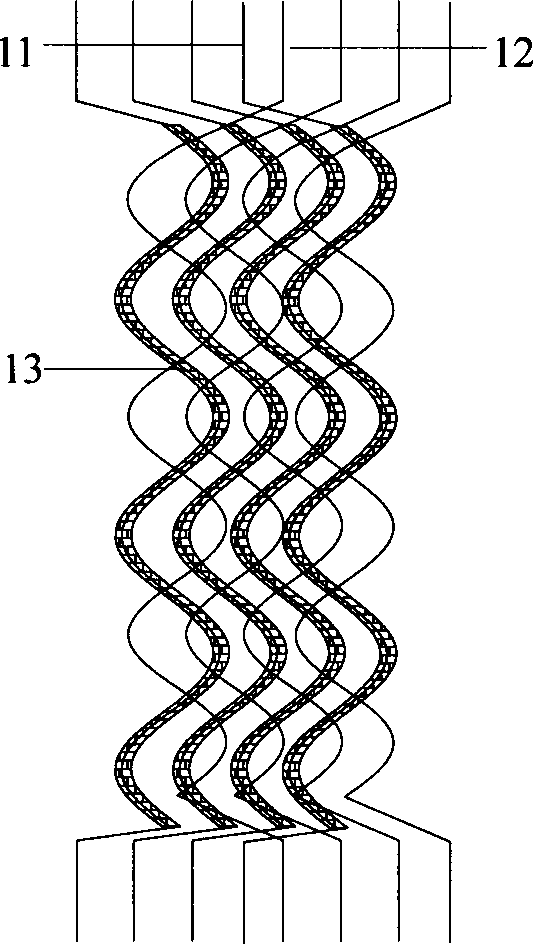

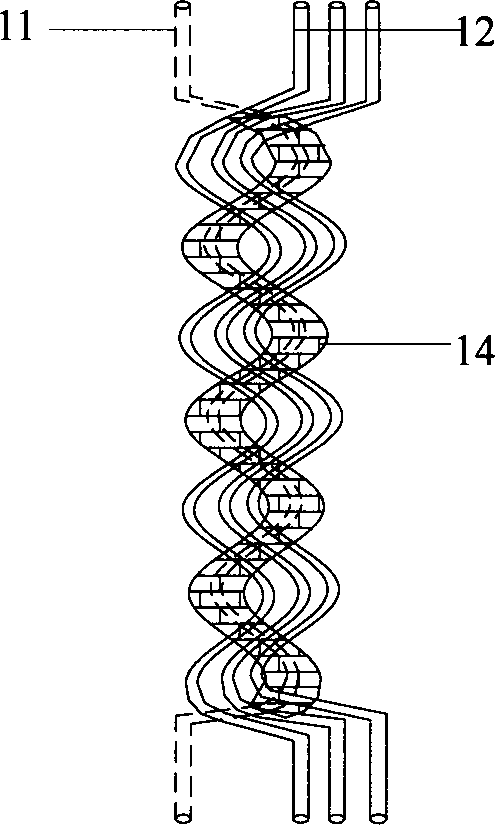

[0057] Embodiment 2: multi-group multi-level mode.

[0058] Inlet of hot liquid and condensate: ordinary sea water, TDS 32800mg / L;

[0059] The inlet temperature of hot liquid and condensate are respectively: 90°C and 25°C;

[0060] Hot liquid, condensate flow rate: 45L / h;

[0061] Solar heat collector heat collection area: 9.00m 2 ;

[0062] The number of hollow fiber membranes in the membrane module is 120, the number of hollow fiber condenser tubes is 360, the hollow fiber material is PTFE, the inner diameter of the hollow fiber membrane is 0.6mm, the thickness is 0.2mm, the average pore diameter is 0.2μm, the porosity is 75%, the inner diameter of the hollow fiber condenser tube is 0.5mm , thickness 0.15mm, the ratio of the number of hollow fiber membranes to hollow fiber condenser tubes is 1:3, the inner diameter of the heat-insulating tubular spacer is 1.0mm, the thickness is 0.5mm, the thickness of the gap between the hollow fiber membranes and the hollow fiber condens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com