Preparation method for NaV2O5

A raw material, sodium carbonate technology, applied in the direction of chemical instruments and methods, vanadium compounds, single crystal growth, etc., can solve the problems of long time, danger, human toxicity, etc., to shorten the sintering time, reduce the risk, and shorten the sintering time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Concrete preparation process steps are as follows:

[0018] Prepare NaV 2 o 5

[0019] ① Weigh the sodium carbonate (Na 2 CO 3 ) 2.12 g, vanadium trioxide (V 2 o 3 ) 1.50 g and vanadium pentoxide (V 2 o 5 ) 5.45 g (the purity of the raw material is above 99%), then mix the three raw materials, put the mixture into an agate mortar, add 10-15 ml of absolute ethanol, grind the mixture until the absolute ethanol evaporates completely, so that the mixture can be mixed uniform.

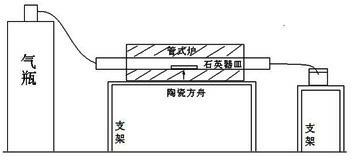

[0020] ② Put the mixture in the ceramic ark, put the ceramic ark into the quartz vessel, put the quartz vessel into the tubular resistance furnace, the quartz vessel is tubular, connect one end to the nitrogen or argon gas cylinder, and the other end to the latex tube, the latex tube comes out Put the air port into a beaker filled with a certain amount of water (for the experimental device, see figure 1 ), open the valve of the gas cylinder, pass nitrogen or argon and other chemically iner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com