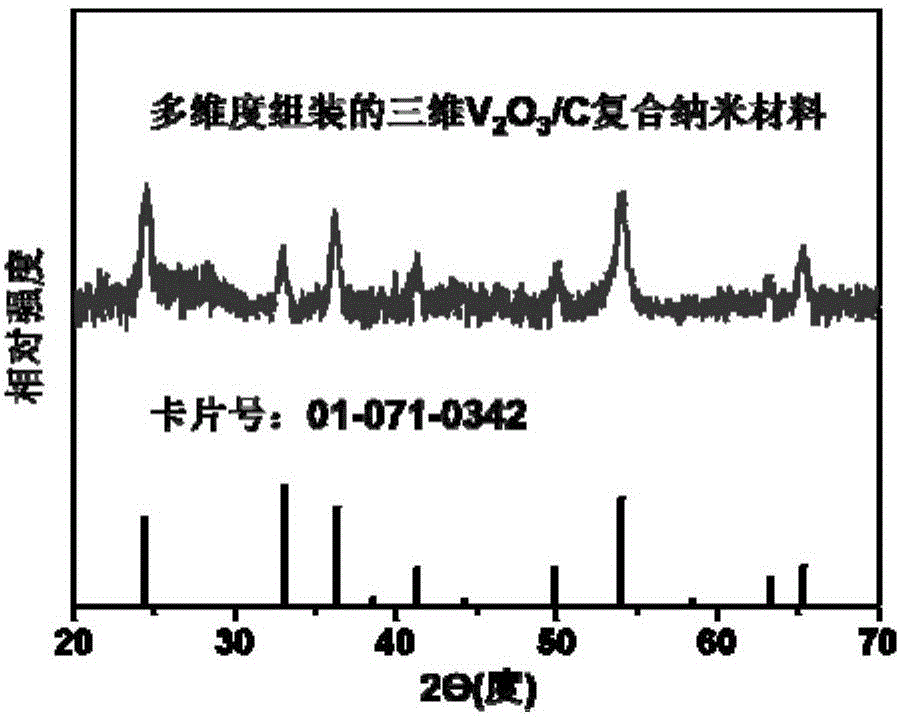

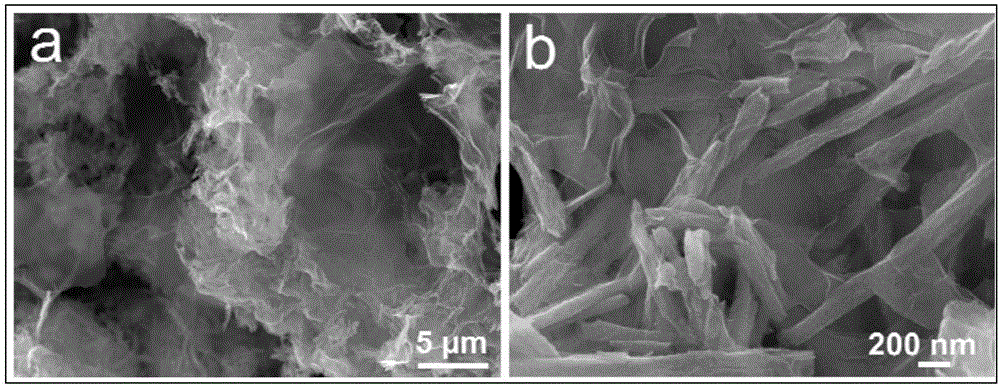

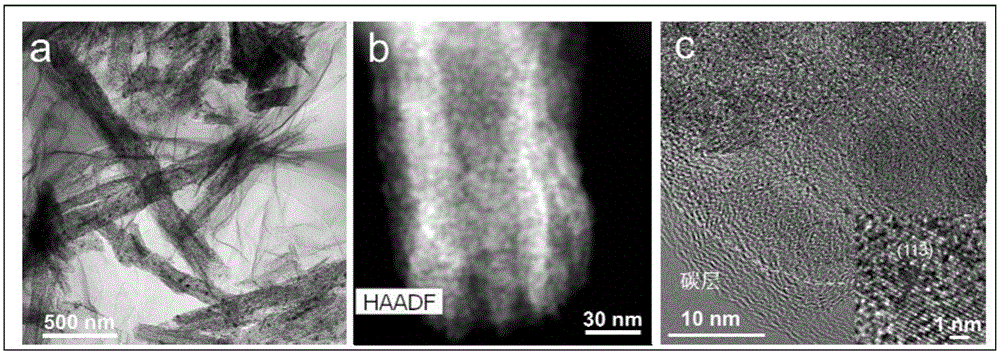

Multi-dimensional assembled three-dimensional vanadium trioxide/carbon composite nano material as well as preparation method and application thereof

A composite nanomaterial, multi-dimensional technology, applied in the field of three-dimensional V2O3/C composite nanomaterials and its preparation, can solve the problem of unreported composite nanomaterials, achieve excellent cycle stability and high rate characteristics, improve cycle life, The effect of relieving expansion stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Three-dimensional V assembled in multiple dimensions 2 o 3 / C composite nanomaterial preparation method, it comprises the steps:

[0034] 1) Weigh 0.8mmol of V 2 o 5 powder and an equal amount of hexadecylamine powder were added to equal volumes of deionized water and absolute ethanol, and stirred evenly;

[0035] 2) Mix and stir the solution obtained in step 1), then transfer the mixed solution into a reaction kettle, react at a temperature of 180° C. for 36 hours, take out the reaction kettle, and naturally cool to room temperature;

[0036] 3) centrifuging the product obtained in step 2), repeatedly washing the obtained precipitate with deionized water and absolute ethanol, and drying in an oven to obtain vanadium oxide nanovolumes;

[0037] 4) Take 200 mg of vanadium oxide nanovolumes obtained in step 3), add them to 5 mL of absolute ethanol, then add reduced graphene oxide with a mass ratio of 8% and 5 mL of deionized water, stir evenly, and then add 10 mg of h...

Embodiment 2

[0045] Three-dimensional V assembled in multiple dimensions 2 o 3 / C composite nanomaterial preparation method, it comprises the steps:

[0046] 1) Weigh 0.8mmol of V 2 o 5 powder and an equal amount of hexadecylamine powder were added to equal volumes of deionized water and absolute ethanol, and stirred evenly;

[0047] 2) Mix and stir the solution obtained in step 1), then transfer the mixed solution into a reaction kettle, react at a temperature of 180° C. for 36 hours, take out the reaction kettle, and naturally cool to room temperature;

[0048] 3) centrifuging the product obtained in step 2), repeatedly washing the obtained precipitate with deionized water and absolute ethanol, and drying in an oven to obtain vanadium oxide nanovolumes;

[0049] 4) Take 150 mg of vanadium oxide nanovolumes obtained in step 3), add them to 5 mL of absolute ethanol, then add reduced graphene oxide with a mass ratio of 8% and 5 mL of deionized water, stir evenly, and then add 10 mg of h...

Embodiment 3

[0054] Three-dimensional V assembled in multiple dimensions 2 o 3 / C composite nanomaterial preparation method, it comprises the steps:

[0055] 1) Weigh 2mmol of V 2 o 5 powder and an equal amount of hexadecylamine powder were added to equal volumes of deionized water and absolute ethanol, and stirred evenly;

[0056] 2) Mix and stir the solution obtained in step 1), then transfer the mixed solution into a reaction kettle, react at a temperature of 200° C. for 72 hours, take out the reaction kettle, and naturally cool to room temperature;

[0057] 3) centrifuging the product obtained in step 2), repeatedly washing the obtained precipitate with deionized water and absolute ethanol, and drying in an oven to obtain vanadium oxide nanovolumes;

[0058] 4) Take 300 mg of the vanadium oxide nanovolumes obtained in step 3), add them to 10 mL of absolute ethanol, then add reduced graphene oxide with a mass ratio of 12% and 10 mL of deionized water, stir evenly, and then add 15 mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com