Carbon-coated vanadium trioxide nano material preparing method and lithium ion batteries

A vanadium trioxide, lithium ion battery technology, applied in secondary batteries, battery electrodes, nanotechnology and other directions, can solve the problems of poor cycle and rate performance, agglomeration and electrode powder, harsh synthesis conditions, etc., to achieve the reaction speed Fast, easy material structure, uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

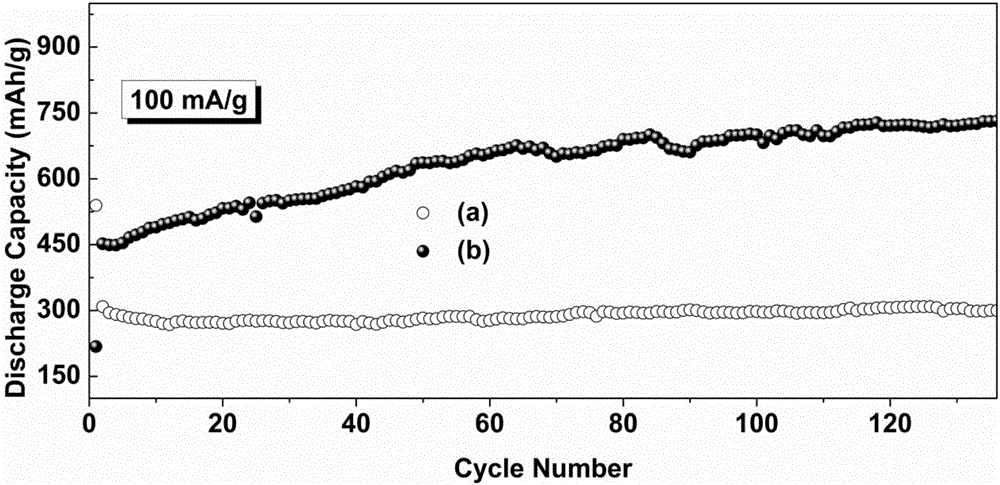

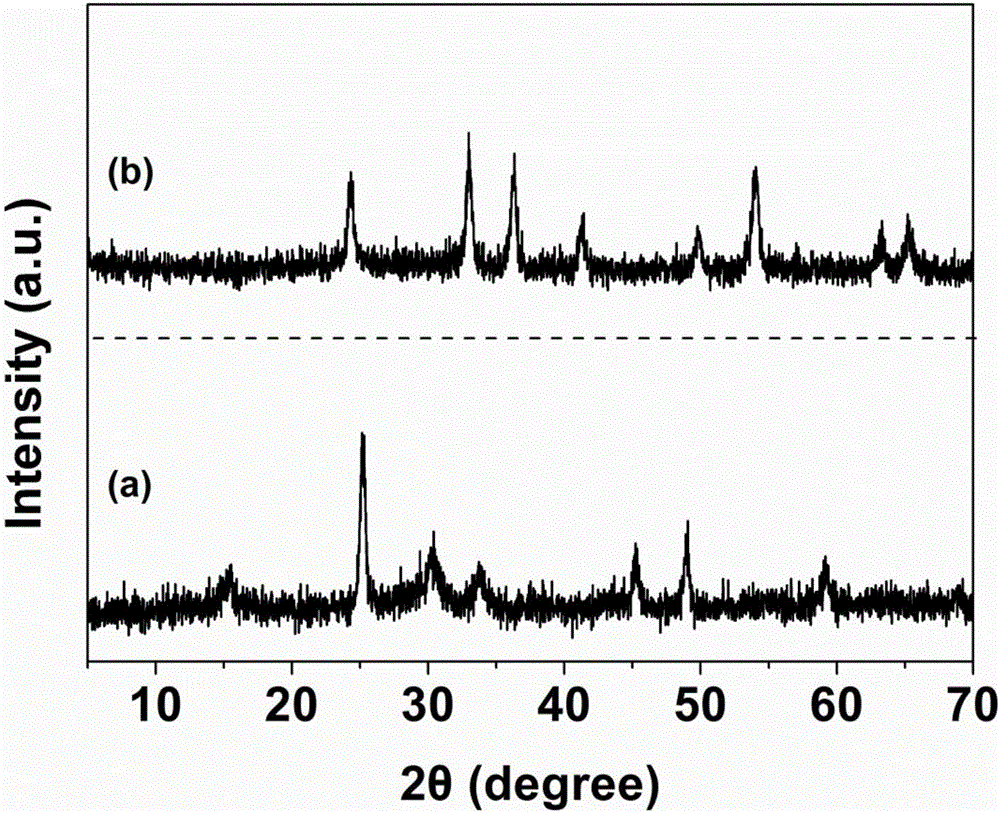

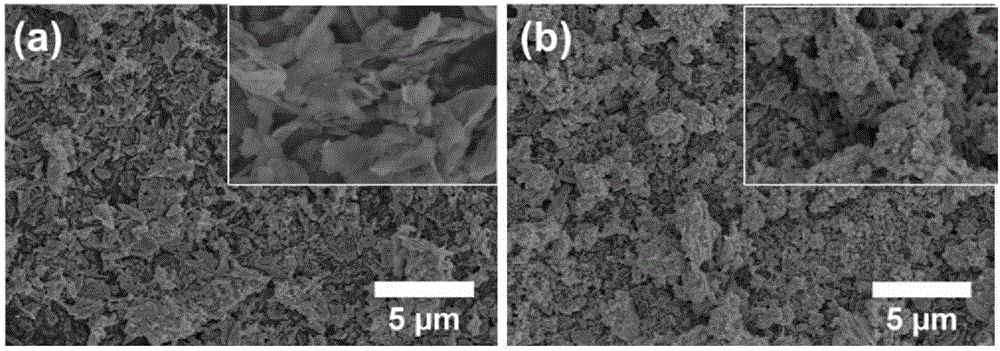

Embodiment 1

[0030] This embodiment is for the preparation of V 2 o 3 nanoparticle approach. Specific steps are as follows:

[0031] (1) Preparation of VO 2 (B) @C nanosheet precursor

[0032] Using high temperature mixed hydrothermal method, according to V 2 o 5 The molar ratio of glucose and glucose was 1:1, weighed and placed in two reaction chambers of a special high-temperature mixed hydrothermal reactor, and added 5ml of deionized water respectively. Then put the reaction kettle into the oven to heat up after sealing, and when the temperature of the oven rises to 200 ° C, the reaction kettle is rotated so that the reactants in the two chambers in the reaction kettle are mixed for hydrothermal reaction, and the heat preservation is continued for 6 hours . After the completion of the hydrothermal reaction, cool to room temperature to obtain VO 2 (B) @C nanomaterials, and washed several times with deionized water and absolute ethanol, put the obtained powder in a vacuum drying...

Embodiment 2

[0038] This example is to prepare 3D hierarchical porous V 2 o 3 @C micro-nano structure method. Specific steps are as follows:

[0039] (1) Preparation of 3D hierarchical porous VO 2 (B) @C micro-nano structure precursor

[0040] Using high temperature mixed hydrothermal method, according to V 2 o 5 The molar ratio of glucose and glucose was 1:1, weighed and placed in two reaction chambers of a special high-temperature mixed hydrothermal reactor, and added 5ml of deionized water respectively. Then put the reaction kettle into the oven to heat up after sealing. When the oven temperature rises to 240 ° C, the reaction kettle is rotated so that the reactants in the two chambers in the reaction kettle are mixed for hydrothermal reaction, and the heat preservation is continued for 6 hours. . After the completion of the hydrothermal reaction, cool to room temperature to obtain VO 2 (B) @C nanomaterials, and washed several times with deionized water and absolute ethanol, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com