LCD (liquid crystal display) integral touch device with an external copper process

A liquid crystal display and touch device technology, applied in the input/output process of instruments, data processing, optics, etc., can solve the problems of large impedance, high impedance ratio, power consumption increase, etc., and achieve channel impedance reduction and touch response speed. , The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the embodiment given with accompanying drawing, but embodiment does not constitute any limitation to the present invention.

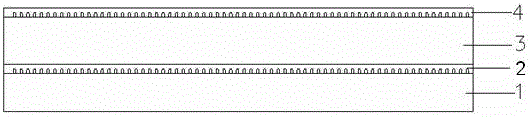

[0028] see figure 1 , an LCD liquid crystal display integrated touch device with external copper process, consisting of a four-layer structure of an upper glass substrate 1, a first metal grid conductive layer 2, an OC insulating layer 3, and a second metal grid conductive layer 4, the upper glass The flexible transparent substrate selected for substrate 1 is one of polymethyl methacrylate, polyurethane and polycarbonate; the OC insulating layer 3 is composed of PI substrate and high insulating material, and is directly coated on the first metal Grid conductive layer 2.

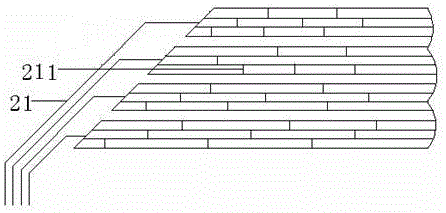

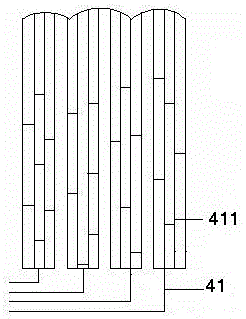

[0029] see figure 1 , figure 2 The first metal grid conductive layer 2 is a layer of metal copper by low-temperature sputtering, and the first metal grid lines 21 are directly formed by exposure and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com