Industrial waste gas desulfurization, denitrification and dust removal equipment

A technology of desulfurization, denitrification, and dust removal equipment, which is applied in the fields of filtration of dispersed particles, transportation and packaging, separation of dispersed particles, etc., which can solve the problems of inconvenient dust particle collection and rapid removal, poor treatment effect and filtration and dust removal effect, and poor treatment effect and filtration effect. and other problems, to achieve the effect of facilitating centralized collection and rapid removal, improving the effect of treatment and reaction, and being beneficial to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

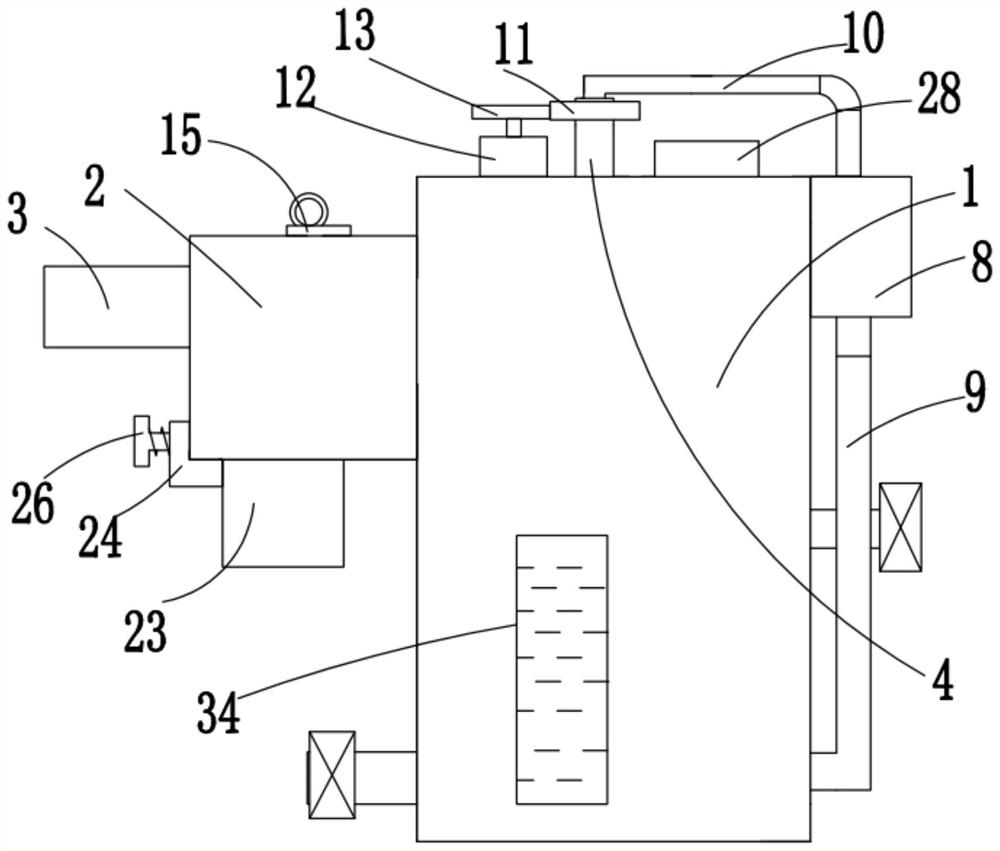

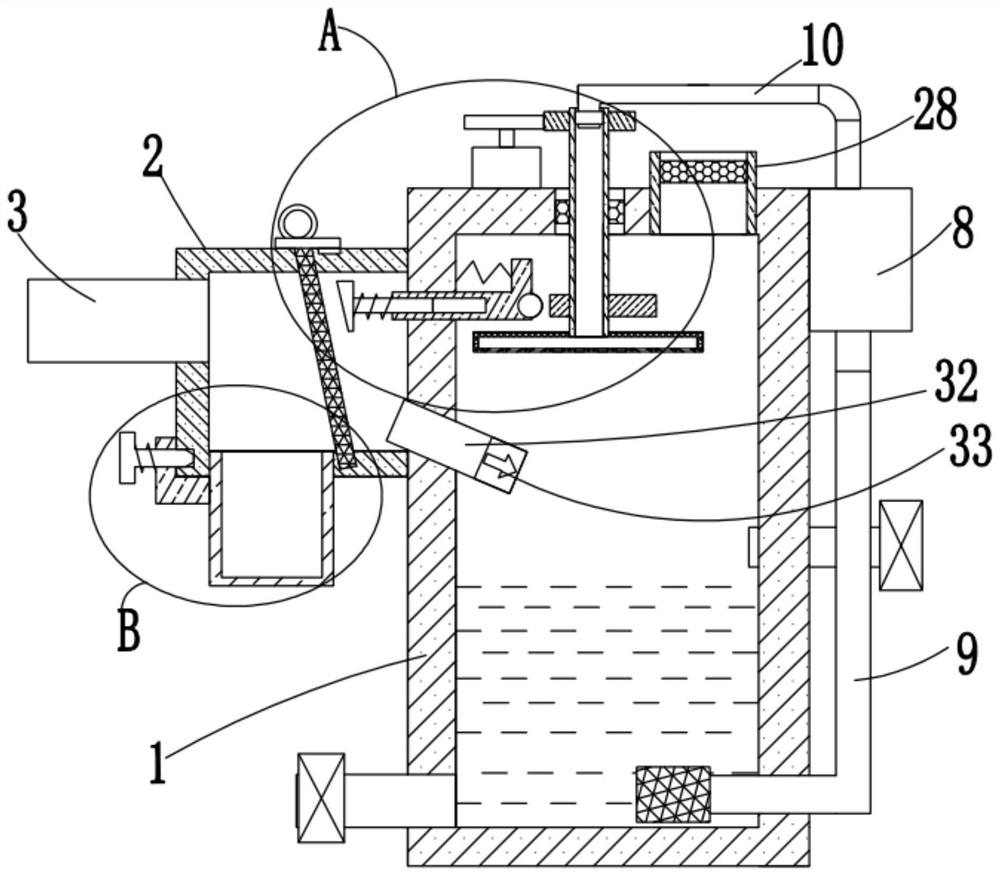

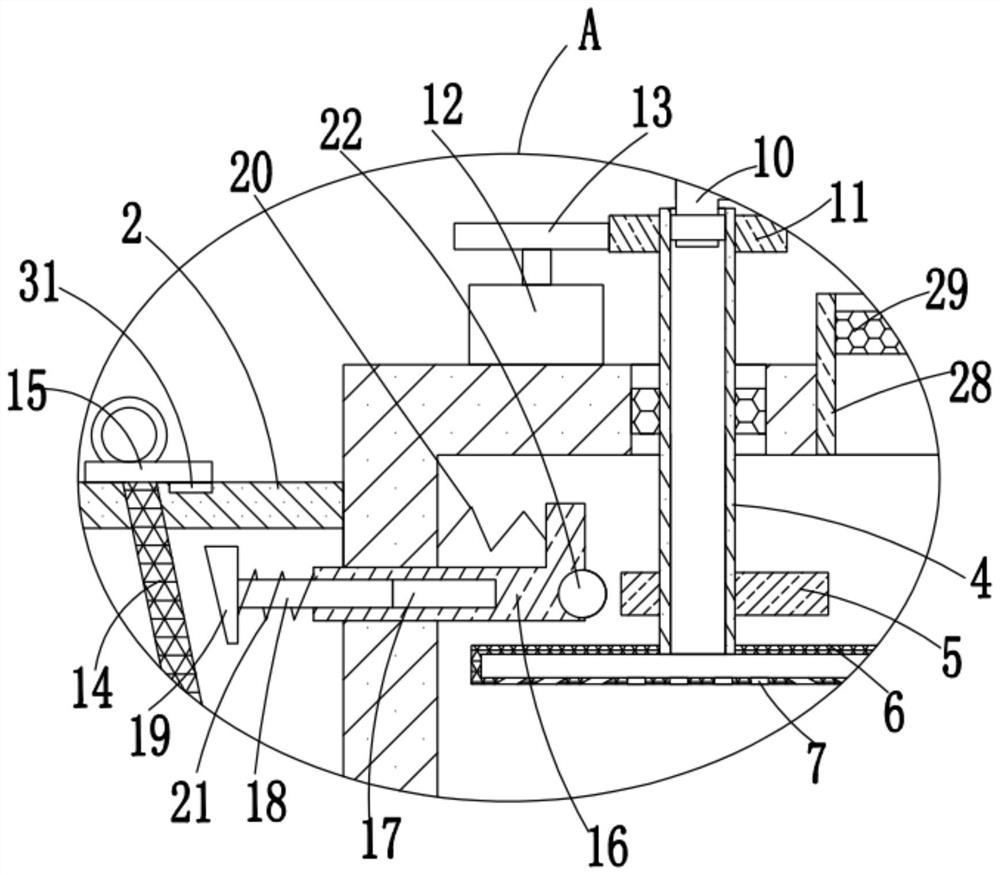

[0028] refer to Figure 1-5, this embodiment proposes an industrial waste gas desulfurization, denitrification and dust removal equipment, including a reaction box 1, the left bottom of the reaction box 1 is connected and fixed with a drain pipe, and the right side of the reaction box 1 is connected and fixed with a water inlet pipe, a drain pipe and The ends of the water inlet pipes far away from each other are connected and fixed with valves. The reaction box 1 is filled with processing liquid. The shower reaction mechanism comprises a vertical pipe 4 that is installed on the top inner wall of the reaction box 1, and the bottom end of the vertical pipe 4 is communicated with and fixed with a horizontal pipe 6 that both ends are a blocking mechanism, and the bottom inner wall of the horizontal pipe 6 is provided with A plurality of water outlet holes 7, the top of the standpipe 4 extends to the top of the reaction box 1, the first gear 11 located above the reaction box 1 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com