MoS2@Cu2S@ copper foam composite nanometer material and preparation method and application thereof

A technology of composite nanomaterials and copper foam, which is applied in nanotechnology, metal material coating technology, liquid chemical plating, etc., can solve the problems of complex preparation process, etc., and achieve the effect of simple operation, large industrial application prospect, and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Cu(OH) 2 Preparation of @foam copper composite nanomaterials:

[0027] First, use absolute ethanol to ultrasonically clean the oil stains on the surface of commercial copper foam, the size of which is 1 × 2 cm 2 , sonicate for 15 minutes, and then use 1 mol / L hydrochloric acid to ultrasonically clean the oxides on the surface of the foamed copper for 30 minutes, and finally use deionized water to ultrasonically clean for 10 minutes, and the treated foamed copper is ready for use.

[0028] Measure 7.5 mL of deionized water into No. 1 and No. 2 centrifuge tubes, add 2.525 g potassium hydroxide to No. 1 centrifuge tube to make a 6 mol / L solution, and add 0.4108 g persulfate to No. 2 centrifuge tube Ammonium, configured as a 0.24 mol / L solution, was sonicated for 15 min until the solid was completely dissolved. Inject the solution in the No. 2 centrifuge tube into the No. 1 centrifuge tube, and then sonicate for 5 minutes. Finally, add the treated foam copper and react at...

Embodiment 2

[0034] MoS 2 @Cu 2 Preparation of S@foam copper composite nanomaterials:

[0035] Measure 30 mg of deionized water into a conical flask, add 45 mg of sodium molybdate dihydrate and 90 mg of thiourea in sequence, and ultrasonicate for 15 min until the solid is completely dissolved. The mixed solution is transferred to a 50 mL autoclave, and finally the Cu(OH) prepared in Example 1 is added. 2@Foam copper composite material, heat up to 180°C, react for 6 h, after the reaction is completed, wash and dry to obtain the target product.

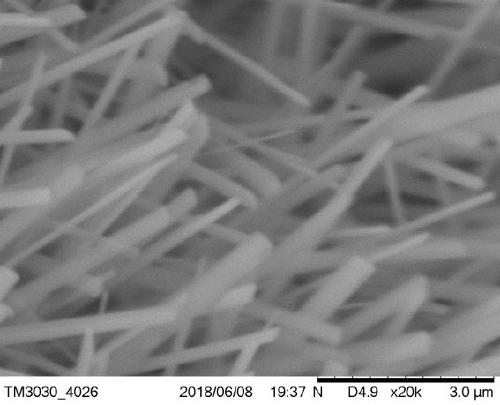

[0036] image 3 MoS prepared for Example 2 2 @Cu 2 The SEM image of the S@foam copper composite nanomaterial, as can be seen from the figure: the prepared MoS 2 @Cu 2 The surface of S nanorods is rough, a small part of the nanorods are agglomerated into spheres, and the average diameter of most of the nanorods is about 500 nm.

Embodiment 3

[0038] MoS 2 @Cu 2 Preparation of S@foam copper composite nanomaterials:

[0039] Measure 30 mg of deionized water into a conical flask, add 45 mg of sodium molybdate dihydrate and 90 mg of thiourea in sequence, and ultrasonicate for 15 min until the solid is completely dissolved. The mixed solution is transferred to a 50 mL autoclave, and finally the Cu(OH) prepared in Example 1 is added. 2 @Foam copper composite material, heat up to 200°C, react for 6 h, after the reaction is completed, wash and dry to obtain the target product.

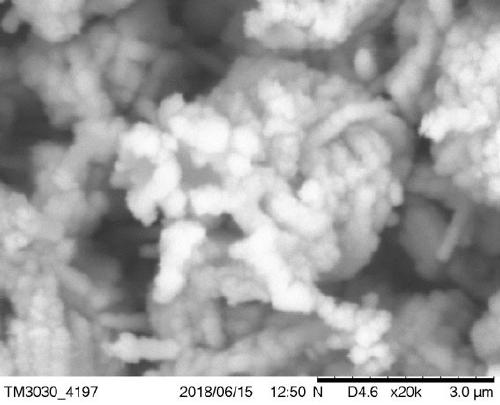

[0040] Figure 4 MoS prepared for Example 3 2 @Cu 2 The SEM image of the S@foam copper composite nanomaterial, as can be seen from the figure: the prepared MoS 2 @Cu 2 The S nanorods have a rough surface and uniform size, and the average diameter of the nanorods is about 600 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com