Stirring device for Kambara reactor (KR) molten iron desulfurization

A technology of molten iron desulfurization and stirring devices, which is applied in the field of desulfurization devices in the metallurgical casting industry, and can solve the problems of many negative effects of the axial stirring force of the stirring head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

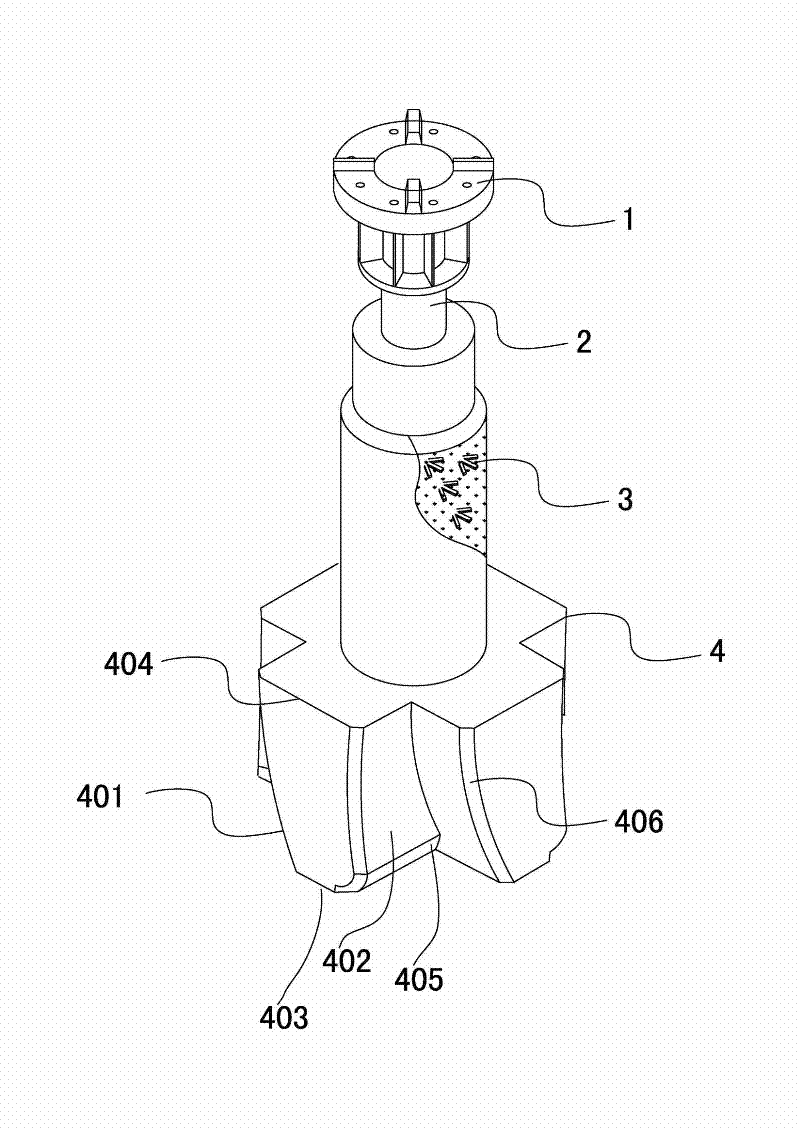

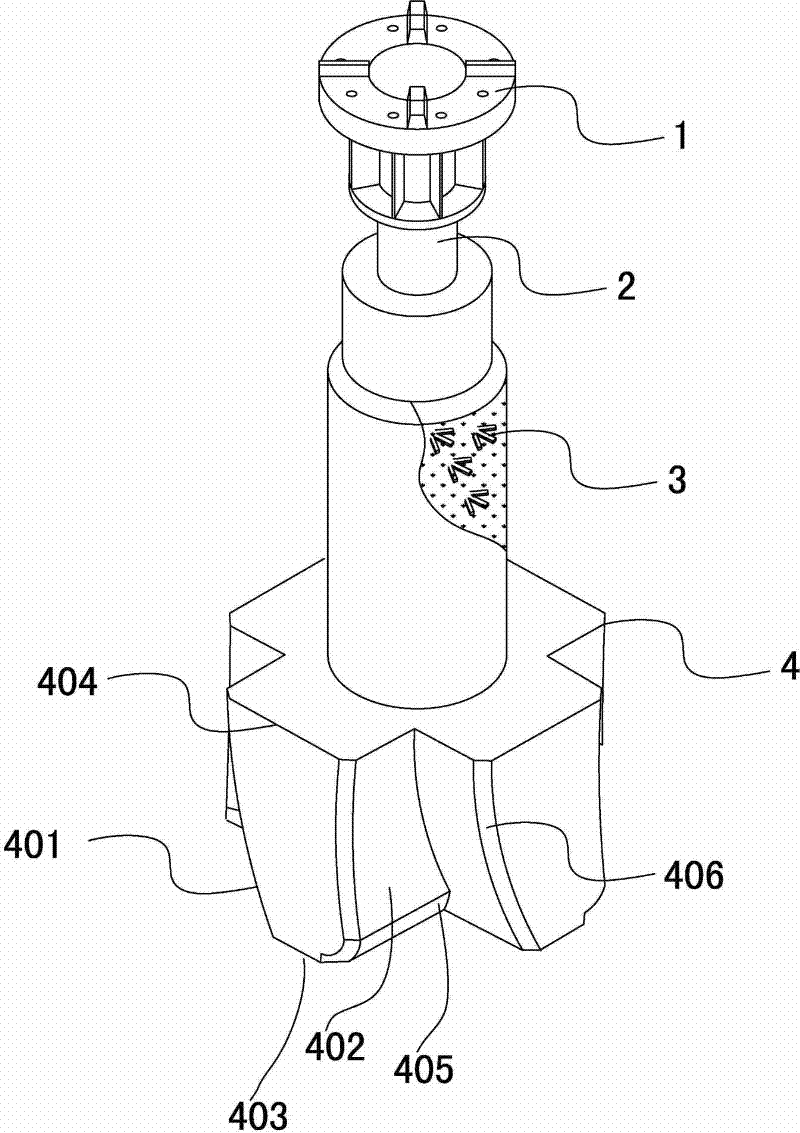

[0014] As shown in the figure, the agitating device for desulfurization of molten iron by the KR method includes a flange connector 1, an agitating shaft 2 fixedly connected to the flange connector 1, and an agitating blade 4 fixedly connected to the lower part of the agitating shaft 2; The iron facing surface 401 of the stirring blade 4 is a convex arc surface; the back iron surface 402 of the stirring blade 4 is a convex arc surface. A skeleton 3 is provided in the outer refractory protective layer of the stirring shaft 2 and in the refractory protective layer of the stirring blade 4 .

[0015] In order to improve the stress distribution in the molten iron stirring area, the width a of the blade bottom 403 of the stirring blade 4 in the present invention is smaller than the width b of the blade top 404 .

[0016] In order to strengthen the vortex effect in the stirring area, the angle 405 between the blade bottom 403 and the back iron surface 402 of the stirring blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com