Molten iron desulfurization stir head

A technology of molten iron desulfurization and stirring head, which is applied in the direction of manufacturing converters, etc., can solve the problems of inconvenient stirring head axial stirring force, high rise height of molten iron liquid level, and poor discharge of molten iron on the back iron surface, so as to improve stirring entrainment Depth, improve utilization efficiency, and improve the effect of comprehensive overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

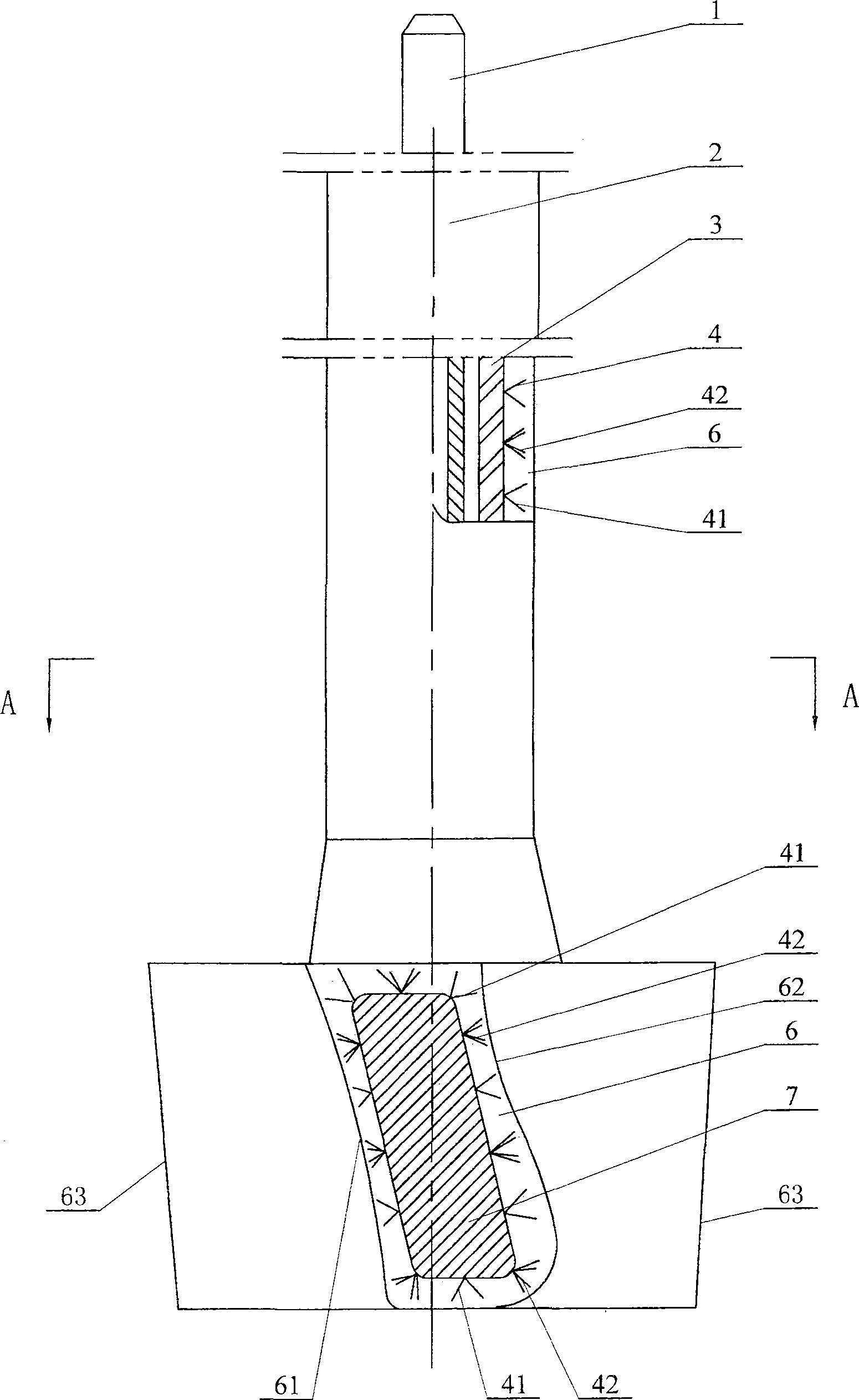

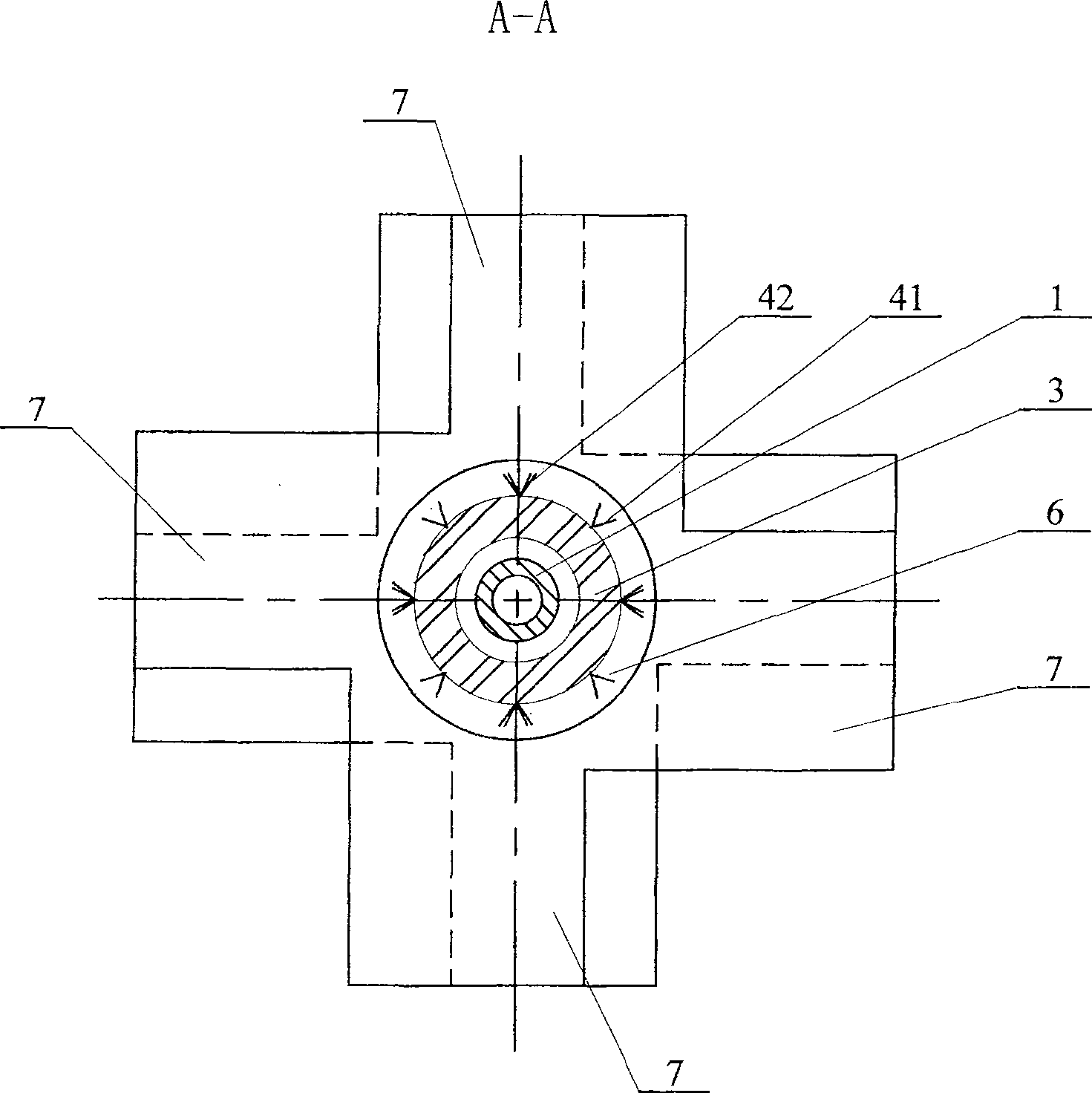

[0011] Specific implementation one: as figure 1 , figure 2 As shown, the stirring head in this embodiment is composed of an air-cooled pipe 1, a stirring head connecting member 2, a metal stirring shaft 3, a riveting member 4, a refractory material working lining 6 and a metal stirring blade 7. The refractory material of the stirring blade is composed of The shape structure of the working lining 6 is: the iron facing surface 61 is a front concave arc surface, the back iron surface 62 is an upper concave convex multi-segment arc surface, and the side surface 63 is an inclined surface from bottom to top. The riveting member 4 has two structures of a V-shaped riveting member 41 and a double-V butterfly riveting member 42, and is welded and arranged at an even interval between the metal stirring shaft 3 and the outer surface of the metal stirring blade 7. Among them, the stirring head connecting member 2 is the same as that in the prior art.

[0012] Further, the axial section ...

specific Embodiment approach 2

[0015] Specific implementation two: as figure 1 , figure 2 As shown, the structure and manufacturing process of this embodiment are the same as those of the first embodiment.

[0016] The difference lies in the material selection of each component: 45# carbon steel seamless steel pipe is used to make air-cooled pipe 1, 20CrMo thick-walled seamless cast steel pipe is used, and ordinary carbon steel threaded steel bar is used to make V-shaped rivet 41 and double V butterfly The riveting member 42 is made of Q235 thick plate to make four metal stirring blades 7, and the refractory working lining 6 is cast as a whole by using corundum mullite castable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com