Sewage disposal system

A sewage treatment system and water outlet technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of affecting the treatment speed, clogged through holes, and poor treatment effect, etc. problem, to achieve the effect of prolonging the reaction time, improving the circulation effect and improving the effect of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

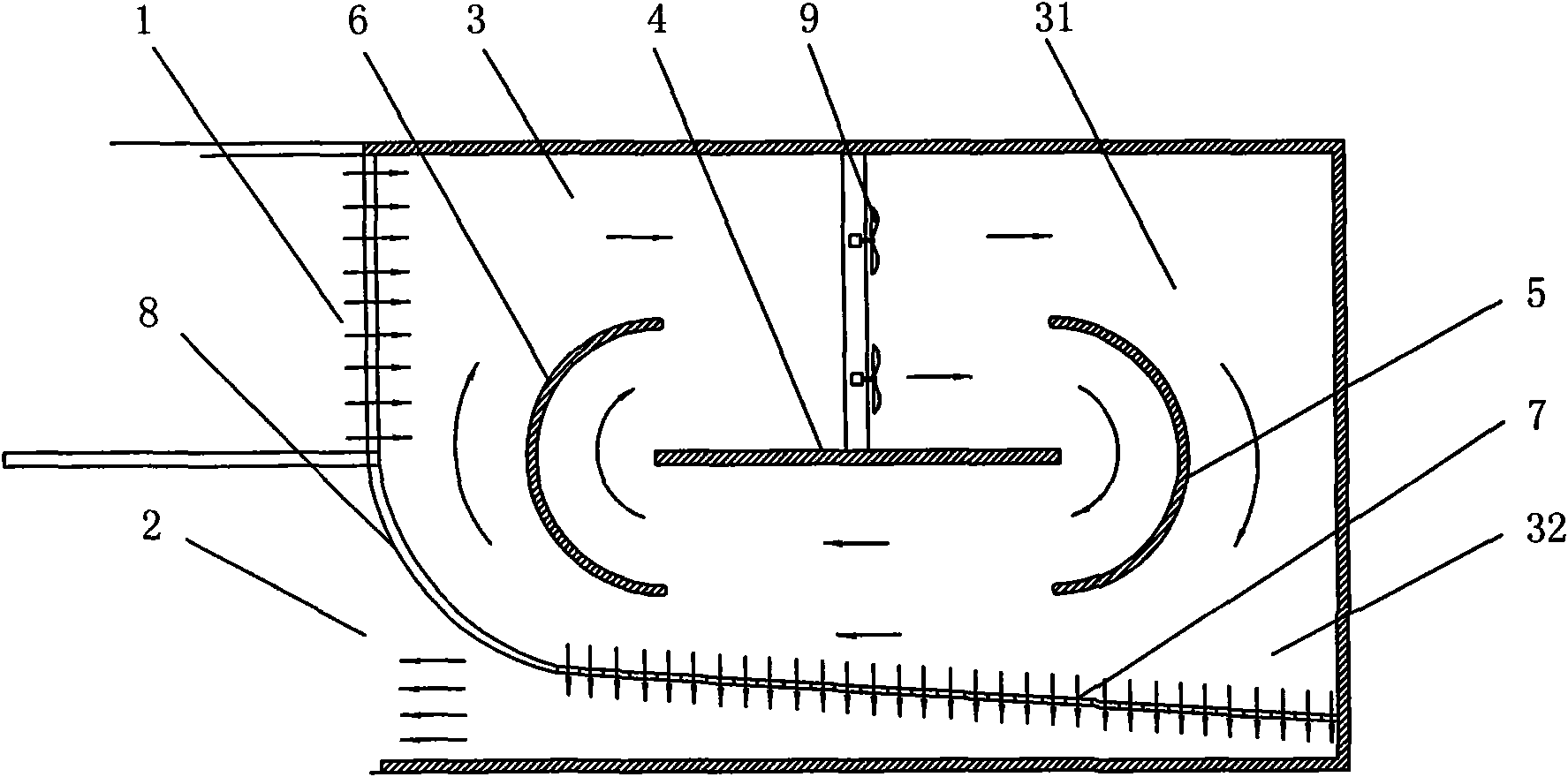

[0013] The present invention is described below in conjunction with accompanying drawing: figure 2 As shown, the sewage treatment system of the present invention includes a water inlet 1, a water outlet 2 and a corridor 3, a large amount of biological filler is placed in the corridor 3, and a straight partition wall 4 is arranged in the middle of the corridor 3, and the straight partition wall 4 is arranged in the middle of the corridor 3. The partition wall 4 divides the corridor 3 into a water inlet corridor 31 and a water outlet corridor 32, and opposite arc-shaped diversion walls 5 and 6 are arranged between the two ends of the straight partition wall 4 and the pool wall of the corridor 3 , the arc-shaped diversion walls 5 and 6 divide the corridor 3 into two circulation spaces; a side outlet screen 7 in the same direction as the partition wall 4 is arranged in the outlet corridor 32, and one end of the side outlet screen 7 is connected to the corridor The pool wall of 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com