Preparation method of Au-Pd/TiO2 NBs photocatalyst

A photocatalyst, au-pd technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as unfavorable separation and small particle size, and achieve Promote rapid transfer, improve absorption, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

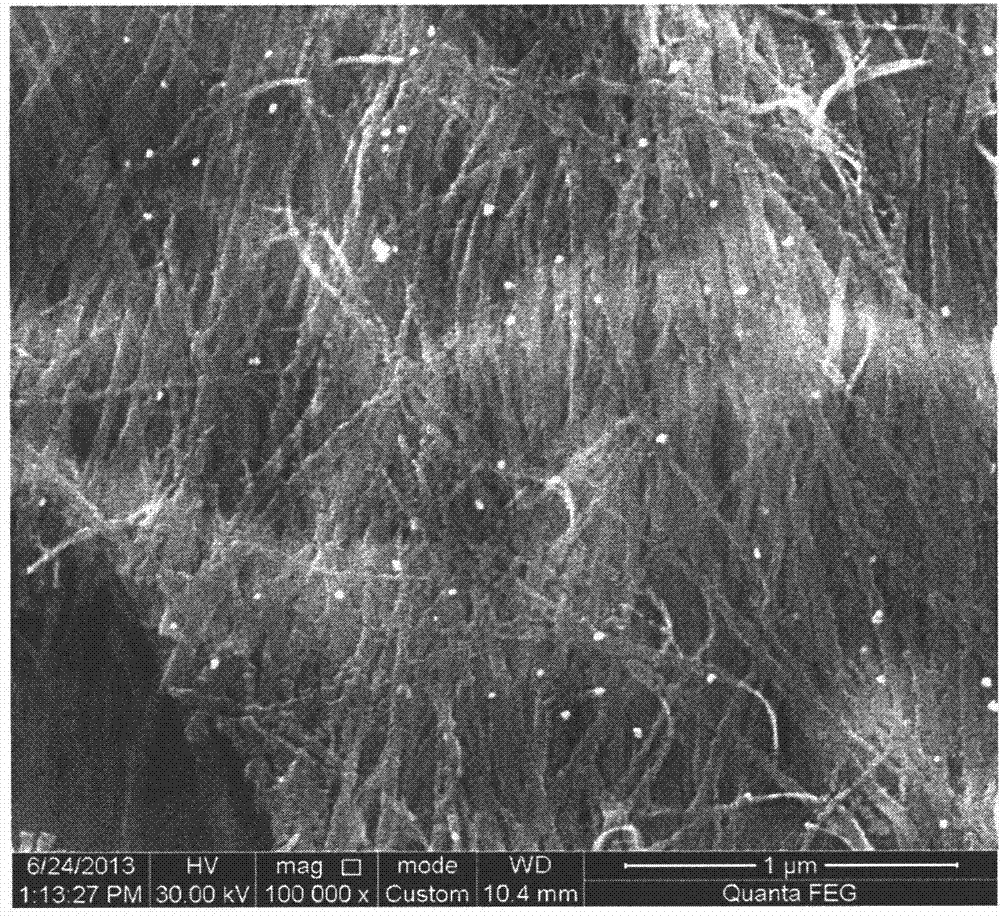

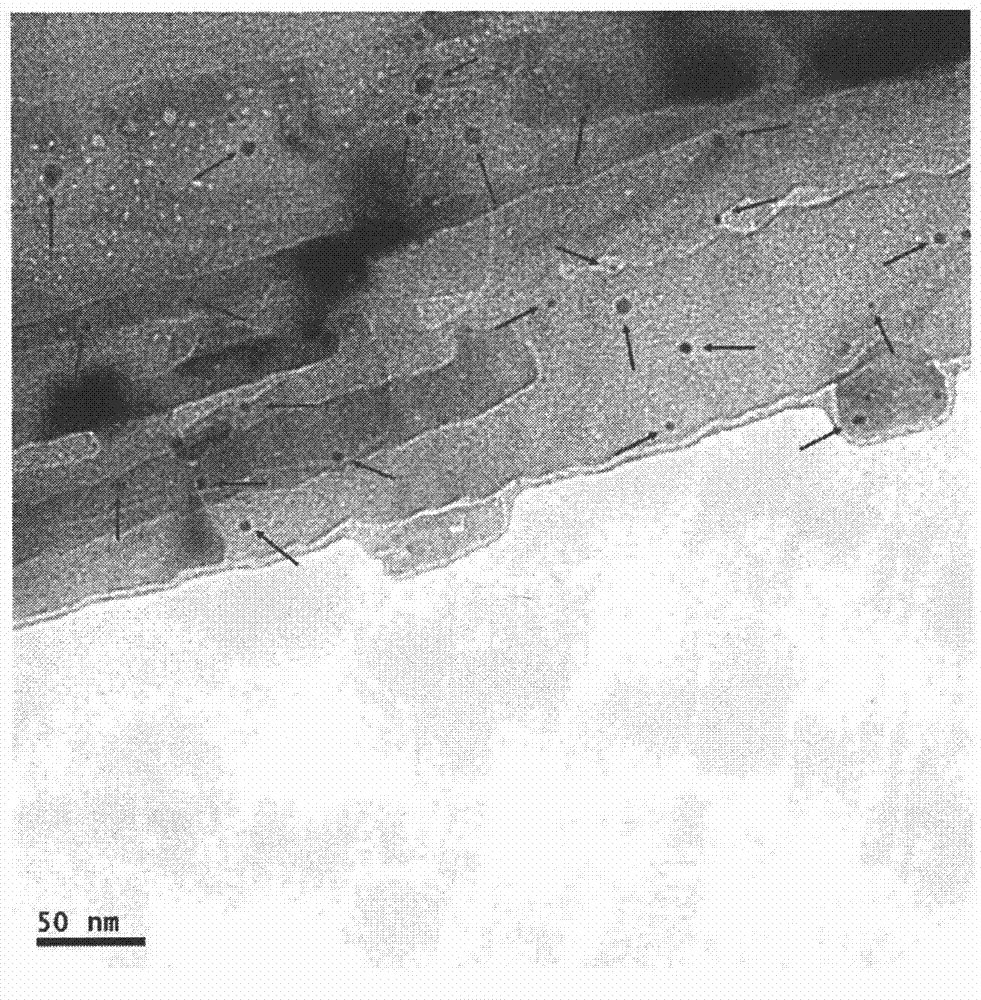

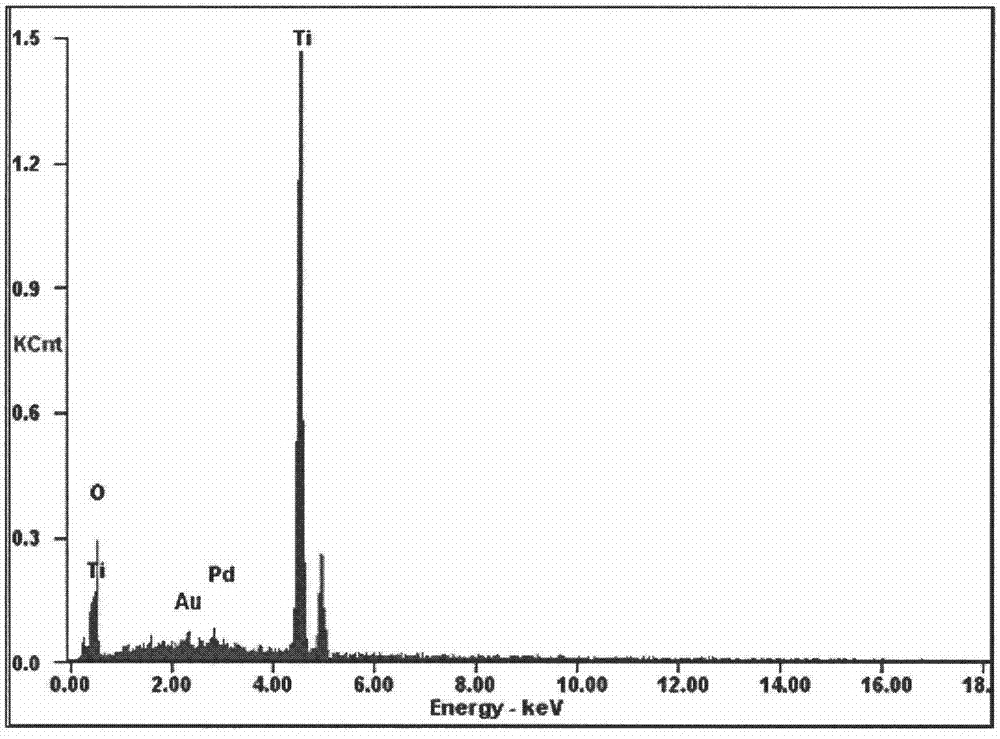

[0018] A kind of Au-Pd / TiO 2 The preparation method of NBs photocatalyst, the steps are as follows:

[0019] 1. TiO 2 Preparation of NBs: using titanium sheet as the substrate, anodizing the titanium sheet to prepare TiO 2 NBs, the electrolyte is ethylene glycol plus water 19:1 (v / v), the content of ammonium fluoride is 0.5wt%, the applied voltage is 60V, the oxidation time is 3h, before anodizing, the titanium sheet is ultrasonicated in ethanol and acetone respectively Wash for 10 minutes, then pickle for 30 seconds, rinse with deionized water, and dry in air at 100°C. Anodic oxidation uses a two-electrode system, and calcines in air at 540°C for 1 hour;

[0020] 2. Modification of Au-Pd bimetallic nanoparticles: TiO prepared in step 1 2 NBs were modified with Au-Pd bimetallic nanoparticles using a three-electrode system, TiO 2 NBs is the cathode, the platinum sheet is the anode, the SCE electrode is the reference electrode, 0.1mM chloroauric acid and palladium chloride a...

Embodiment 2

[0024] A kind of Au-Pd / TiO 2 The preparation method of NBs photocatalyst, the steps are as follows:

[0025] 1. TiO 2 Preparation of NBs: TiO was prepared by anodizing a 9mm×40mm×0.5mm titanium sheet 2 NBs, the electrolyte solution is ethylene glycol plus water (19:1v / v), the ammonium fluoride content is 0.4wt%, the applied voltage is 60V, and the oxidation time is 4h. Before anodizing, the titanium sheet was ultrasonically cleaned in ethanol and acetone for 10 min, and then acid-washed for 30 s (HF:HNO 3 :H 2 O=1:4:5), rinsed with deionized water, and dried in air at 105°C. Anodizing uses a two-electrode system. The prepared samples were calcined at 550 °C for 2 h in air.

[0026] 2. Modification of Au-Pd bimetallic nanoparticles: on prepared TiO 2 NBs were modified with Au-Pd bimetallic nanoparticles using a three-electrode system, TiO 2 NBs is the cathode, the platinum sheet is the anode, the SCE electrode is the reference electrode, 0.1mM chloroauric acid and palla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com