Gas circulation biological bubble tower methane/natural gas biological desulfuration method

A technology of gas circulation and biological desulfurization, which is applied in the field of biogas/natural gas biological desulfurization, can solve the problems of poor hydrogen sulfide solubility, failure to meet the use standard, and reduced desulfurization efficiency, so as to increase desulfurization efficiency, increase yield, and improve desulfurization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

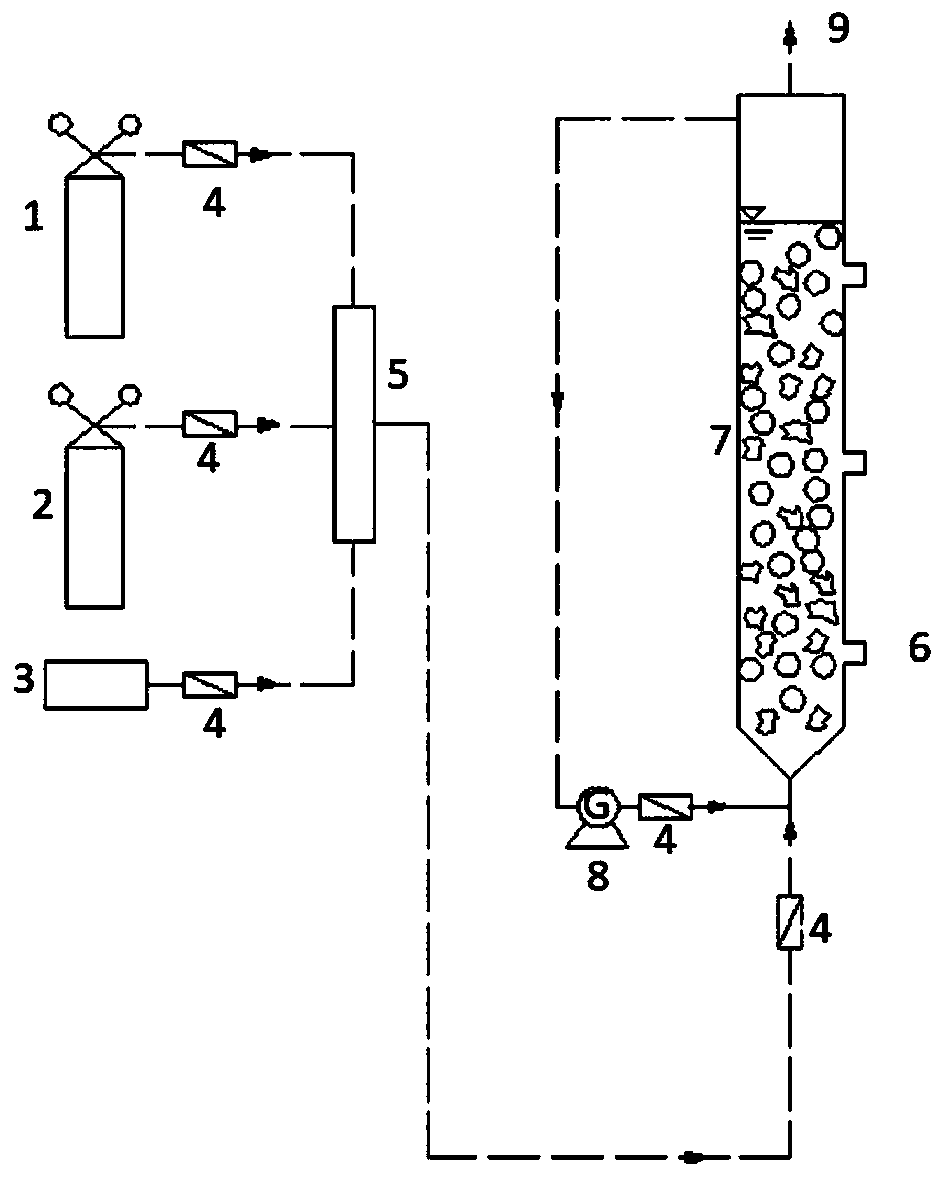

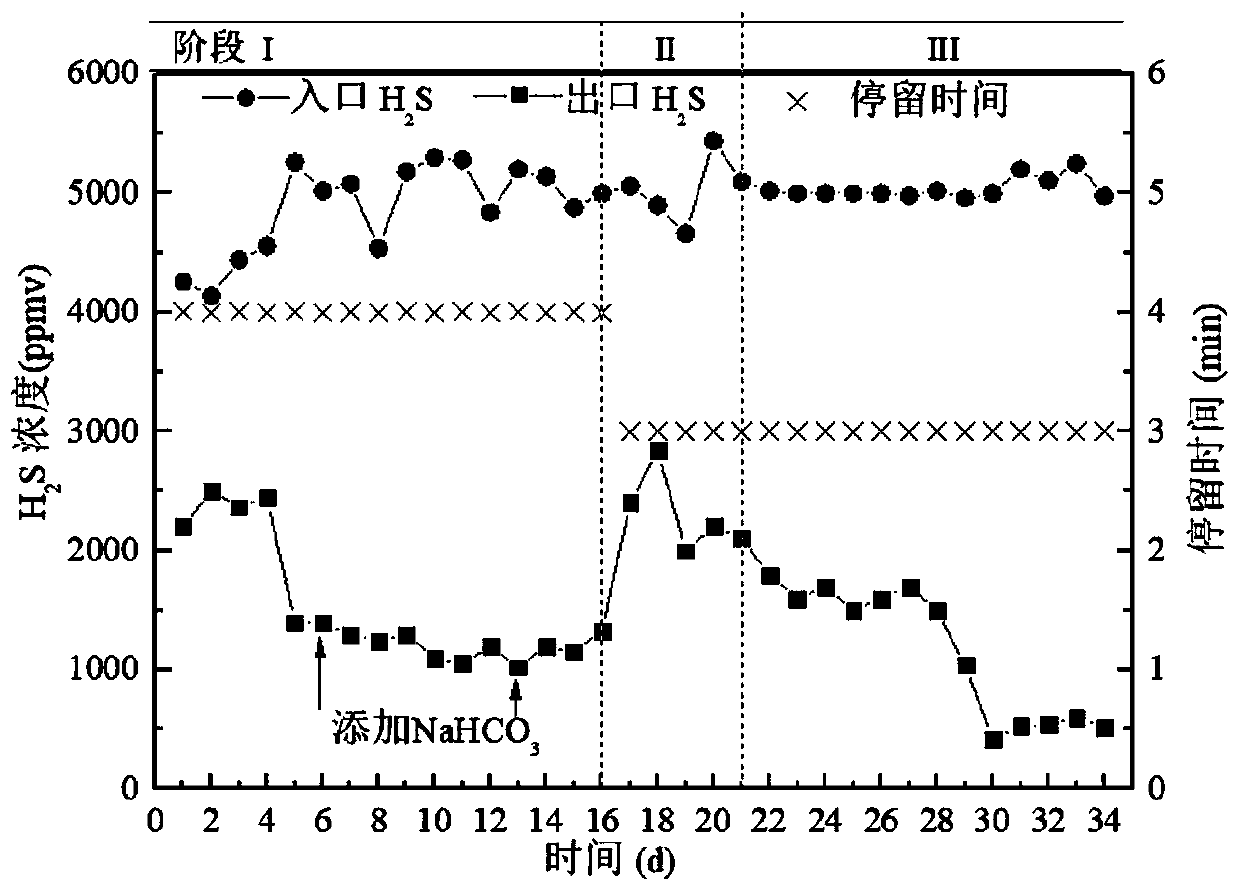

[0049] use figure 1 Shown biological bubble tower system ( figure 1 Middle --- means gas path), the filler is modified biological suspension filler, the material is polypropylene, and the density is 0.92g / cm 3 , The porosity is 84%, the specific surface area is 1200m 2 / m 3 , The filler volume is 0.25L, and the solution volume is 650mL. The simulated biogas (hydrogen sulfide content is about 0.5%) is made by mixing two gas cylinder gases in a certain proportion: (1) Ordinary nitrogen (N 2 ≥99.5%); (2)H 2 S standard gas (H 2 S is about 10%, the rest is N 2 ). O required for biological desulfurization 2 It is supplied by an air pump, and the air and the simulated biogas are evenly mixed and enter the reactor. The gas flow rate of the inlet pipe of the reactor is the same as the gas flow rate of the outlet pipe. The composition of the nutrient solution is shown in Table 1, with NaHCO added 3 As an inorganic carbon source for desulfurization bacteria (in actual production, the bioga...

Embodiment 2

[0062] use figure 1 The shown biological bubble column system, the filler is modified biological suspended filler, the material is polyethylene, and the density is 0.94g / cm 3 , Porosity is 90%, specific surface area is 1153m 2 / m 3 , The filler volume is 0.25L, and the solution volume is 650mL. The simulated biogas (hydrogen sulfide content is about 0.5%) is made by mixing two gas cylinder gases in a certain proportion: (1) Ordinary nitrogen (N 2 ≥99.5%); (2)H 2 S standard gas (H 2 S is about 10%, the rest is N 2 ). O required for biological desulfurization 2 It is supplied by an air pump, and the air and the simulated biogas are evenly mixed and enter the reactor. The gas flow rate of the inlet pipe of the reactor is the same as the gas flow rate of the outlet pipe. Nutrient solution components are shown in Table 1, add NaHCO 3 As an inorganic carbon source for desulfurization bacteria, 1 mol / L hydrochloric acid and sodium hydroxide solution were used to adjust the pH value of ...

Embodiment 3

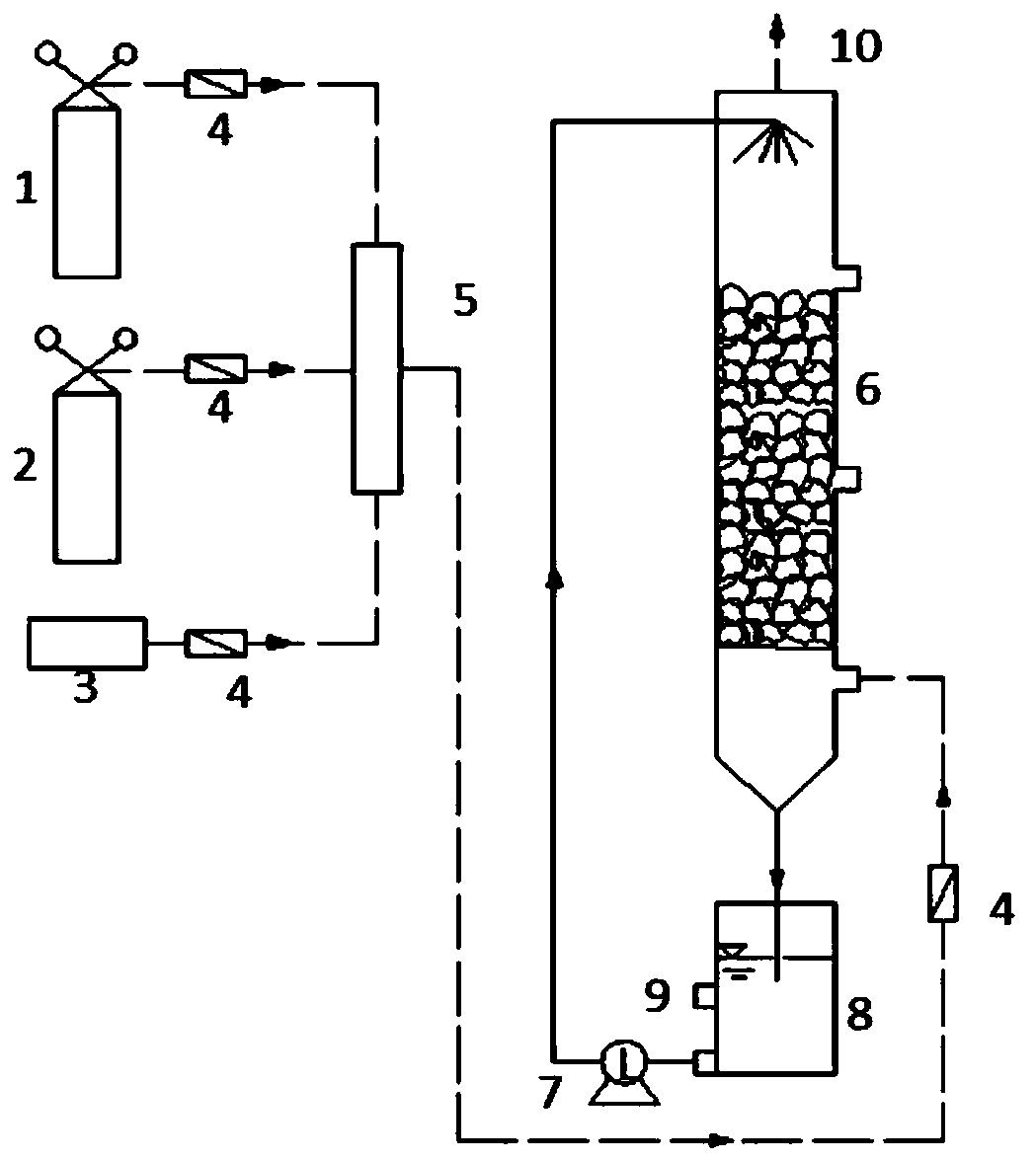

[0073] Respectively adopt figure 1 Shown biological bubble tower and figure 2 The shown biological trickling filter system ( figure 2 Middle——indicating waterway, ---indicating airway), the filler is modified biological suspension filler, the material is polyurethane, the density is 0.93g / cm 3 , The porosity is 87%, the specific surface area is 1450m 2 / m 3 , The filler volume is 0.25L. The volume of nutrient solution in the biological bubble tower is 650 mL. The nutrient solution of the biological trickling filter is trickling filtrate with a volume of 650 mL, which is separately placed in the circulating liquid tank and supplied to the bed of the trickling filter through a liquid circulating pump. Simulated biogas (with a volume fraction of about 0.5% H 2 S) Two cylinder gases are mixed according to a certain ratio: (1) Ordinary nitrogen (N 2 ≥99.5%); (2)H 2 S standard gas (H 2 S is about 10%, remaining gas is N 2 ). O required for biological desulfurization 2 Supplied by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com