Magnetic ferric oxide desulfurizer and preparation method thereof

A magnetic iron oxide and desulfurizing agent technology, which is applied in chemical instruments and methods, separation methods, combustible gas purification, etc., can solve the problems of insufficient contact between desulfurizing agent and sulfur-containing gas, low mechanical strength, etc., and achieve mechanical strength, The effect of improving mechanical strength and increasing sulfur capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a magnetic iron oxide desulfurizer and a preparation method thereof, the preparation method comprising the following steps:

[0042] S1. After putting 400g of α-FeOOH, 20g of alumina, 30g of fly ash and 10g of squash gum into a mixer and milling for 5 minutes, mixture I was obtained;

[0043] S2. Add 5 g of acetic acid and 200 g of water to the mixture I, continue to mix and grind for 10 minutes, and knead fully to obtain the mixture II;

[0044] S3. Put the mixture II into a screw extruder and extrude it into a strip shaped product of Φ4×2-10mm;

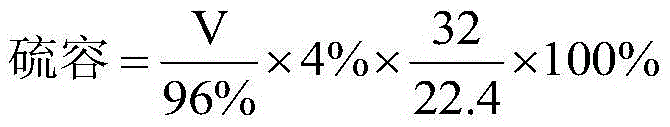

[0045] S4. Dry the strip shaped product at -5°C for 24 hours, and roast the dried material at 200°C for 6 hours to obtain a magnetic iron oxide desulfurizer. After testing, the sulfur capacity of the desulfurizer is 47.6%, and it is resistant to crushing in the radial direction. The force is 96N / cm, and the specific surface area is 105m 2 / g, pore volume 0.48ml / g.

[0046] According to the water re...

Embodiment 2

[0049] This embodiment provides a magnetic iron oxide desulfurizer and a preparation method thereof, the preparation method comprising the following steps:

[0050] S1. Put 900g of β-FeOOH, 100g of diatomaceous earth, 50g of volcanic ash and 100g of guar gum into a mixer and grind for 30 minutes to obtain the mixture I;

[0051] S2, add 100g of nitric acid and 400g of water to the mixture I, continue to mix and mill for 30min, after fully kneading, obtain the mixture II;

[0052] S3. Put the mixture II into a screw extruder and extrude it into a strip shaped product of Φ4×2-10mm;

[0053] S4. Dry the strip shaped product at 120°C for 3 hours, and roast the dried material at 300°C for 3 hours to obtain a magnetic iron oxide desulfurizer. The sulfur capacity of the desulfurizer is 44.8% after testing, and the radial crushing resistance It is 105N / cm, and the specific surface area is 95m 2 / g, pore volume 0.45ml / g.

[0054] According to the water resistance evaluation test, th...

Embodiment 3

[0057] This embodiment provides a magnetic iron oxide desulfurizer and a preparation method thereof, the preparation method comprising the following steps:

[0058] S1, put the carboxymethyl cellulose of the gamma-FeOOH of 700g, 300g pseudo-boehmite, 100g fly ash and 200g into the mixing mill and grind for 15min to obtain the mixture I;

[0059] S2, add 150g of hydrochloric acid and 300g of water to the mixture I, continue to mix and grind for 20min, after fully kneading, obtain the mixture II;

[0060] S3. Put the mixture II into a screw extruder and extrude it into a strip shaped product of Φ4×2-10mm;

[0061] S4. Dry the strip shaped product at 100°C for 10 hours, and roast the dried material at 400°C for 12 hours to obtain a magnetic iron oxide desulfurizer. The sulfur capacity of the desulfurizer is 43.7% and the radial crushing resistance is tested. It is 96N / cm, and the specific surface area is 92m 2 / g, the pore volume is 0.39ml / g.

[0062] According to the water re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com