Calcium oxide based high-temperature carbon dioxide adsorbent material doped with inert component and preparation method

An inert component, carbon dioxide technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve problems such as unfavorable industrial production of adsorbents, unfavorable adsorption processes, and reduced adsorption capacity, and is suitable for large-scale production. Application, good cycle stability, effect of grain size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

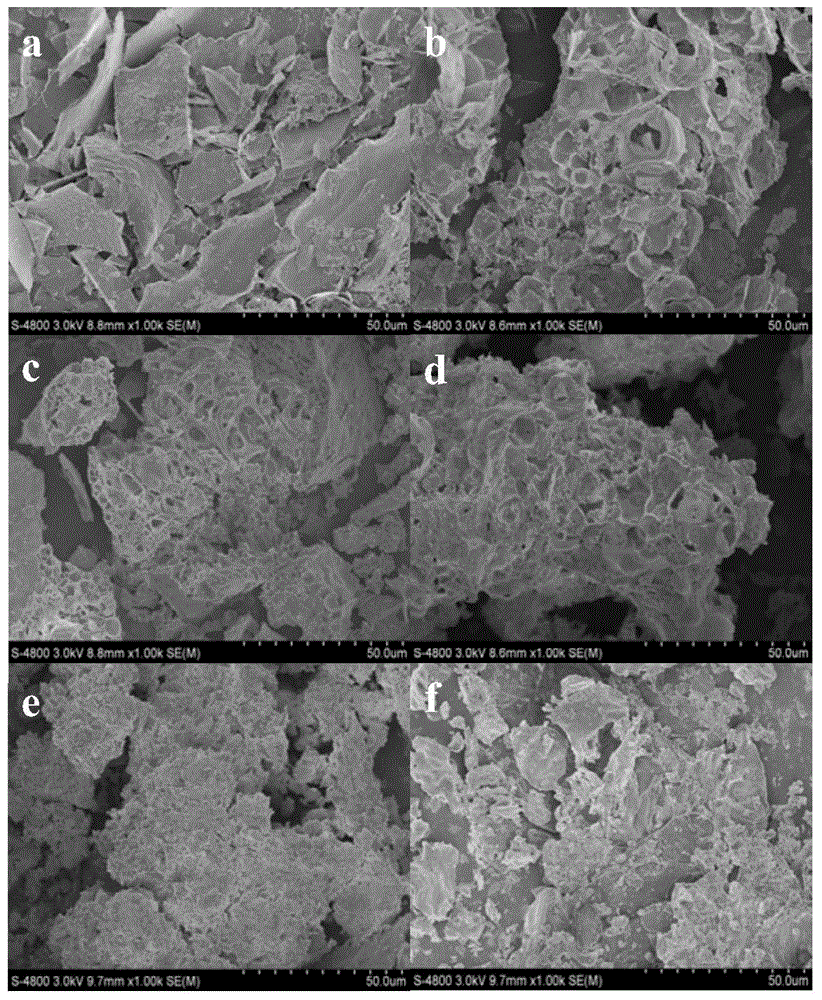

[0030] Sol-gel preparation of calcium oxide-based adsorbent doped with cerium oxide:

[0031] First, water is used as a solvent to dissolve calcium nitrate and cerium nitrate respectively, wherein the molar ratio of calcium nitrate and cerium nitrate is 15:1, and the dissolved nitrate solutions are mixed. Add citric acid to the mixed solution of nitrate, the ratio of citric acid to the total moles of metal ions is 2:1. After the citric acid was completely dissolved, the mixture was placed on a rotary evaporator, the temperature of the water bath was set at 70°C, and the time of the water bath was 3 hours, so that calcium and cerium could be evenly complexed. After bathing in water for 3 hours, the excess water was removed by vacuum to obtain a sol, and the sol was dried in an oven at 100° C. for 12 hours. The expanded and loose powder obtained after drying is put into a muffle furnace for roasting to obtain a calcium oxide-based adsorbent doped with cerium oxide.

Embodiment 2

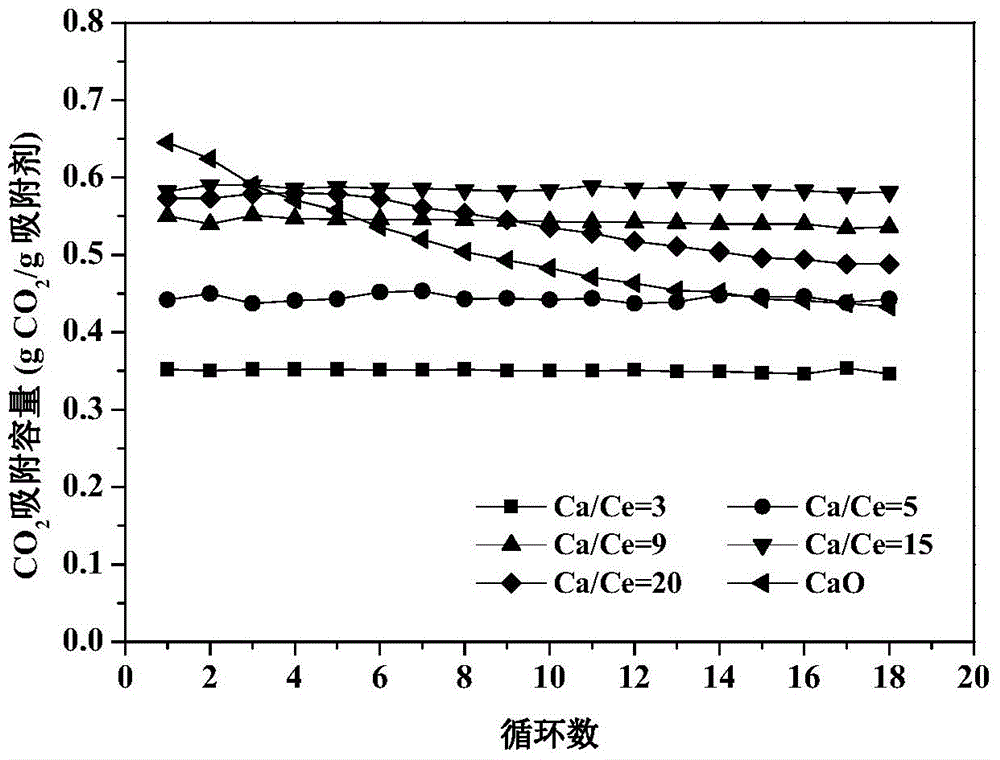

[0033] Using the preparation method in Example 1, the molar ratios of calcium nitrate and cerium nitrate were adjusted to be 3:1, 5:1, 9:1, 20:1, respectively, and pure CaO was used to prepare a series of calcium oxides with different ratios of calcium to cerium base adsorbent.

Embodiment 3

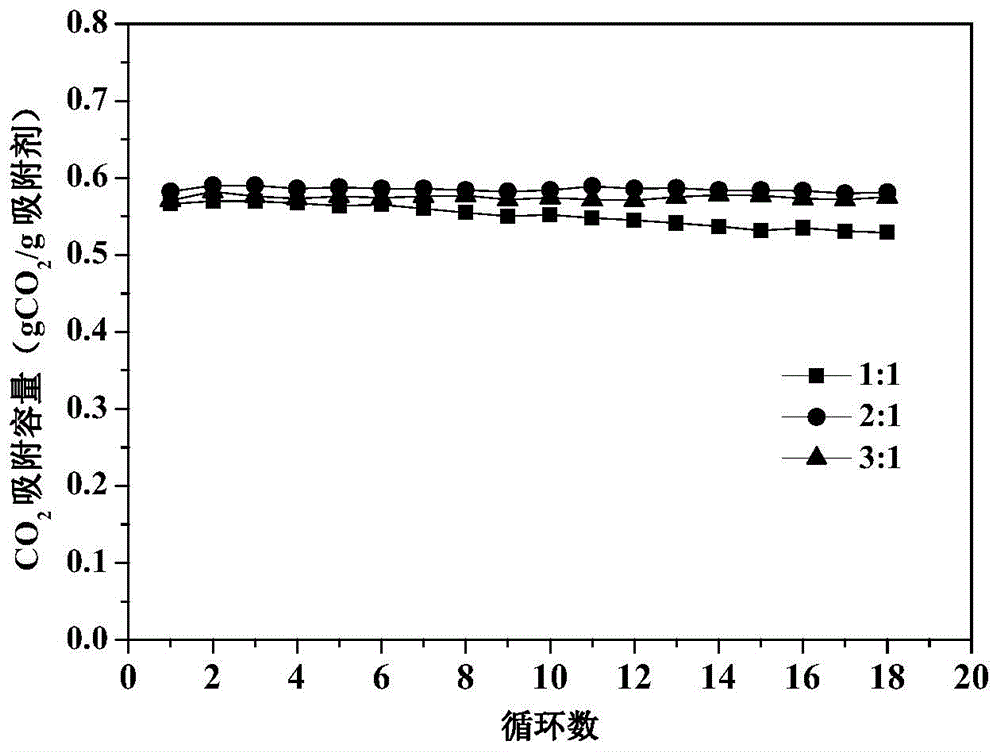

[0035] Using the preparation method in Example 1, adjust the ratio of citric acid to the total moles of metal ions to be 1:1, 3:1, and prepare a series of calcium oxide-based adsorbents with different amounts of citric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com